Starting the engine & running-in ('breaking-in) – O.S. Engines 12TZ(P) User Manual

Page 9

16

STARTING THE ENGINE & RUNNING-IN ('Breaking-in)

PRESSURIZED FUEL SYSTEM

Before starting the engine, always

check the tightness of all the screws

and nuts especially those of joint and

movable parts such as throttle arm.

Missing retightening the loose screws

and nuts often causes the parts break-

age that is capable of harming you.

Never run your vehicle without installing the

air cleaner. Dust and dirt that may otherwise

be drawn into the engine will rapidly shorten

its life.

The somewhat violent changes of vehicle

attitude that occur in off-road running,

combined with the fact that, in buggy type

cars, the fuel tank is often located some

distance from the carburetor, means that fuel

'head' at the carburettor can vary and upset

running.Therefore,it is recommended that a

muffler pressurized fuel feed system be used.

Lay the chassis on a stand and start the

engine so that the tiers may not be in

contact with the ground.

Running- in is a procedure for an engine to

come close to actual running conditions

(fuel, r.p.m., engine temperature, etc.).

Excessively rich running and prolonged

low speed running mean nothing. Prolon-

ged low speed running and low tempera-

ture running may result in the oil in the fuel

being gelled and piston/liner being agglu-

tinated.

Try to make time to run the car at full throttle.

Lengthen full throttle running time gradually.

When the car can run full throttle with rich

mixture at the straight, close the needle-valve

a little. Repeat this procedure until the car runs

at the maximum speed at the latter straight

course.

17

The following procedure is suitable for these

engines when the O.S. T-1040 tuned silencer

and a fuel containing up to 30% nitrome-

thane are used.

Fill the tank completely with fuel.

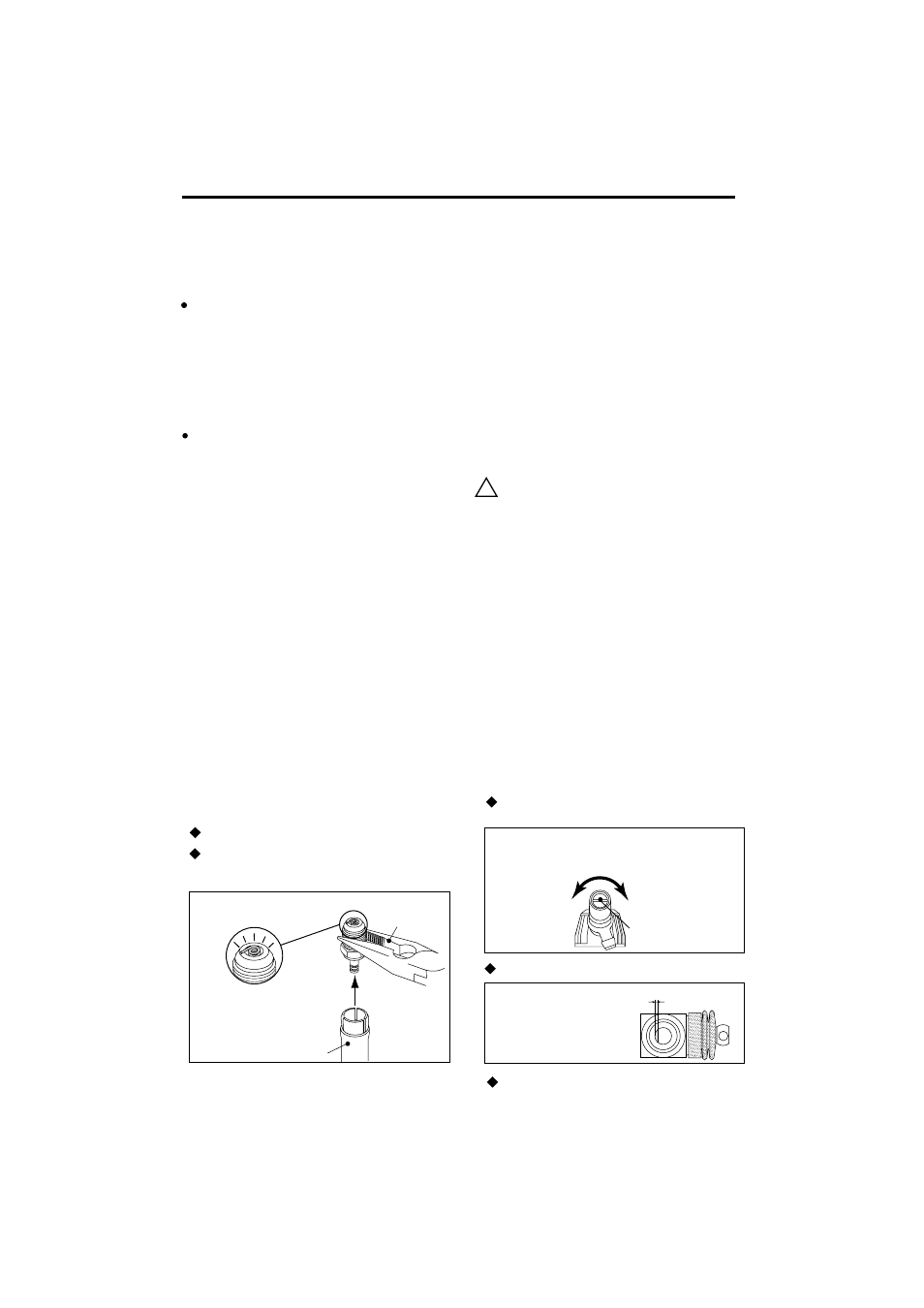

Temporarily remove the glowplug to check

that it glows bright red when energized.

Glow Plug Igniter

Pliers

Element glows when energized.

Replace the plug when the

element does not glow or is

burnt out.

Turn the needle-valve clockwise until it stops. This

is the fully closed position. Do not force it to turn

further.

Metering needle and mixture control valve

are set at basic position. (Refer to P23.)

Needle Valve

Open

Close (clockwise)

approx 0.5mm

The carburetor is set as shown below at the

factory. Start the engine as it is.

The needle-valve is set approx. 1-3/4 turns

opened from the fully closed position.

Throttle is set approx. 0.5mm open.

Approx. 0.5mm open

factory setting with the

reducer removed