NORAC UC4+BC+MC2 User Manual

Page 26

23

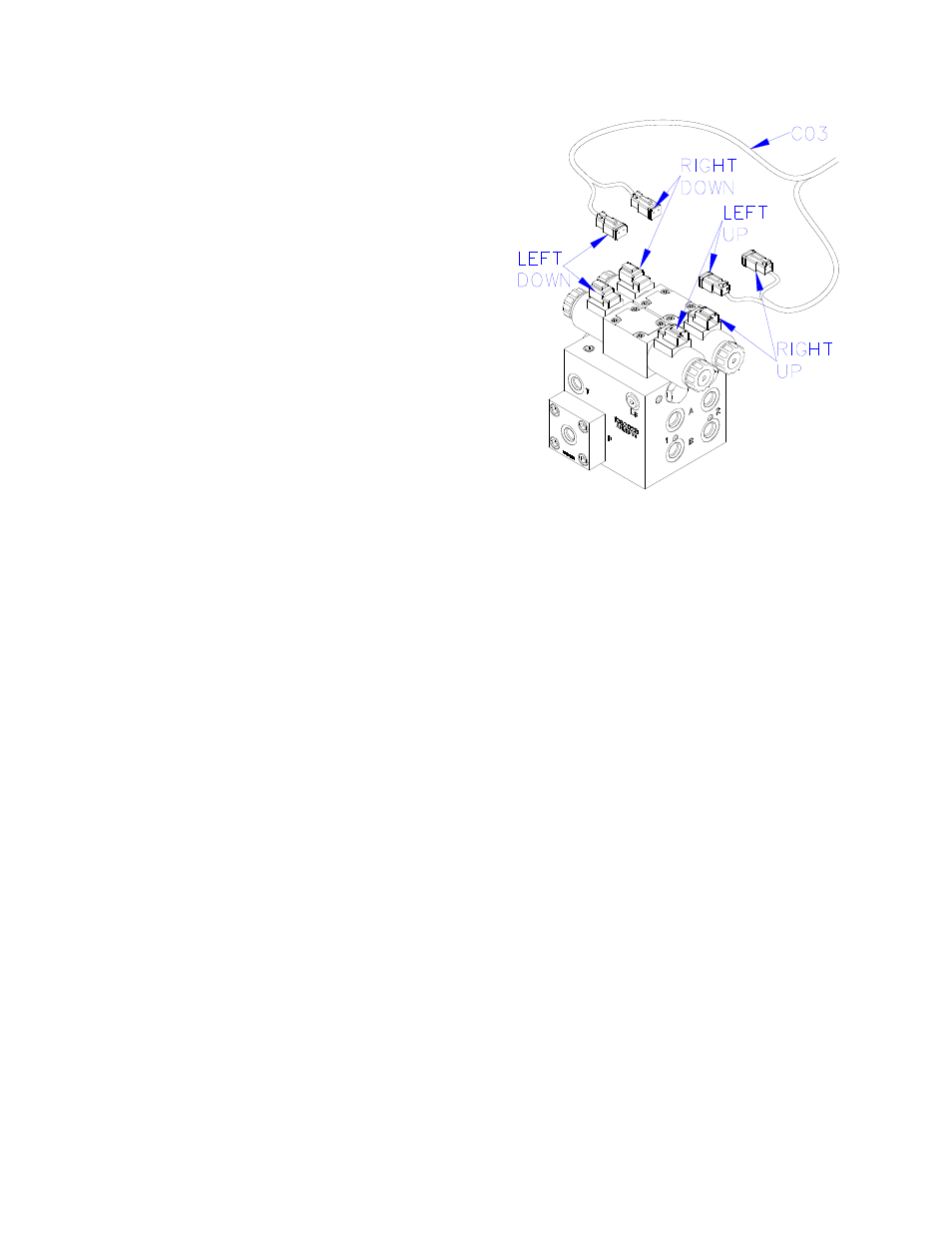

7. Route C11 to the rear of the sprayer,

in the vicinity of the valve block.

8. Connect the 6-pin shroud (S6) on C12

to the mating connector (T6A) on C11

(Figure 26).

9. Route the free end of C12 to the Miller

valve block and insert the 2-pin tees

between the matching valve

connections. For each tee, the function

(e.g. “Main Up”) is labeled on the branch

wire.

10. Unplug the connectors on the existing

valves. There are 4 connectors to

unplug (as labeled on the valve bank):

LEFT UP, LEFT DOWN, RIGHT UP and

RIGHT DOWN. Plug in the 2-pin tower

of C12 to the matching existing valve

connections. For each connector, the

function (e.g. “LEFT UP”, etc.) is labeled

on the branch wire.

11. Connect the 6-pin tower on the valve

cable (C03) onto the mating connector

(S6A) on C11 (Figure 26).

12. Route the free end of C03 to the

vicinity of the NORAC valve block.

13. The connectors on the valve cable

(C03) are marked RIGHT UP, LEFT

UP, RIGHT DOWN and LEFT

DOWN. Cables labeled with UP go

on the same side as the hydraulic hoses.

Figure 27: Valve Cable Connections

14. Connect the AMP 4-pin plug – P4 (C11)

to the 4-pin AMP receptacle on the tee

of C05 (Figure 28).

15. Route the sensor roll bias cable (C05)

to the chassis roll sensor. Follow

existing cables and/or hydraulic lines.

16. Connect the CAN Node cable (C02B)

to the 4-pin AMP plug on the tee of

C05 (Figure 28).

17. Route the CAN Node cable (C02B) to

the roll sensors. Follow existing cables

and/or hydraulic lines.

18. Connect the sensor branch cable (C02)

to the 4-pin AMP plug on C02B

(Figure 28).

19. Route the sensor branch cable (C02) to

the wing and main sensors. Follow

existing cables and/or hydraulic lines

along the boom.

20. Cable-tie the installed cables every 12

inches.