Moniteur – Moniteur 40 Series VALVE Positioners User Manual

Page 3

Moniteur

M O N I T E U R D E V I C E S I N C O R P O R A T E D

3 6 C o m m e rc e R o a d , C e d a r G ro v e , N J 0 7 0 0 9 Te l . ( 9 7 3 ) 8 5 7 - 1 6 0 0 F a x ( 9 7 3 ) 8 5 7 - 7 2 8 9

w w w . m o n i t e u r d e v i c e s . c o m

Page 2

Input Signal

3 - 15 psig

Split Range Available

Impedance

N/A

Stroke Range:

0 - 90°

Supply Range:

20 to 100 PSIG

Air Delivery:

7 SCFM

Air Consumption:

0.26 SCFM

Operating Temperature:

-4° to +158° F

Linearity

+/- 1%

Hysteresis

1% max.

Sensitivity

+/- 0.5%

Repeatability

+/- 0.5%

Pneumatic Connections:

1/8 NPT - Gauge Ports

1/4 NPT - Supply / Outlet

Enclosure:

Designed to NEMA 4, 4X

Enclosure Weight:

Approx. 4.8 lbs.

Input Signal

4 - 20 mA @ 24 VDC

Split Range Available

Impedance

250 +/- 15 ohms

Stroke Range:

0 - 90°

Supply Range:

20 to 100 PSIG

Air Delivery:

7 SCFM

Air Consumption:

0.15 SCFM

Operating Temperature:

-4° to +158° F

Linearity

+/- 1%

Hysteresis

1% max.

Sensitivity

+/- 0.5%

Repeatability

+/- 0.5%

Pneumatic Connections:

1/8 NPT - Gauge Ports

1/4 NPT - Supply / Outlet

Enclosure:

Designed to NEMA 4, 4X

Enclosure Weight:

Approx. 6.5 lbs.

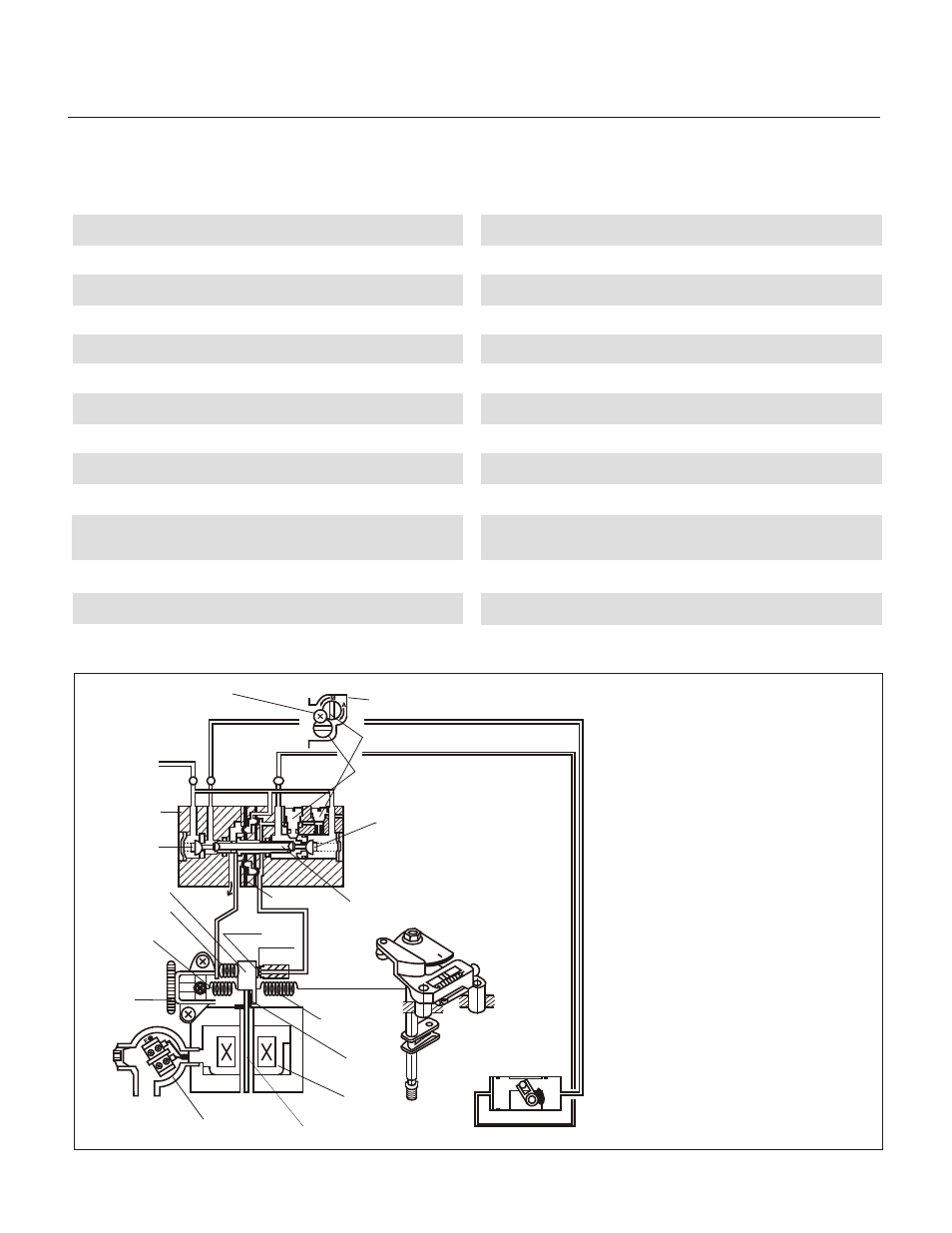

Specifications -3-15 psi Pneumatic

Air Supply

Pilot Valve

Inlet Valve B

Counter Weight

Compensation

Spring

Zero

adjusting

Spring

Zero

adjusting

Screw

Flapper

Nozzle

Automatic

Manual

Inlet Valve A

Actuator

Terminal Box

Armature

Torque

Motor

Plate

Spring

Feedback

Spring

Stopper Screw

Do not move

Sensitivity adjusting screw

(Adjusts GAIN)

Change-over screw

(Built-in bleed restriction)

Exhaust Valve

Diaphragm

Principle Of Operation

As the signal current from the controller

increases, the plate spring of the torque

motor works as a pivot. As the armature

receives the rotary torque in the counter-

clockwise direction, the counter-weight

is pushed to the left, the clearance

between the nozzle and the flapper will

increase, and the nozzle back pressure

will decrease. As a result, the exhaust

valve of the pilot valve moves to the

right, and the output pressure of OUT1

increases (as OUT 2 decreases) to

move the actuator.

The movement of the actuator in turn

rotates the feedback shaft and spring.

The actuator stays in the position where

the spring force is balanced with the

force generated by the input current in

the torque motor. The compensation

spring is for direct feedback of the

motion of the exhaust valve, and is

connected to the counter weight to

enhance the stability of the loop. The

zero point is adjusted by changing the

zero adjustment spring tension.

Specifications - 4-20 mA Electro-Pneumatic

OUT 1

OUT 2

Installation and Operating Instructions

Series 40 Positioners