Milwaukee Tool 5316-21 User Manual

Page 3

4

5

Grounded tools require a three wire extension

cord. Double insulated tools can use either a two

or three wire extension cord. As the distance from

the supply outlet increases, you must use a heavier

gauge extension cord. Using extension cords with

inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the

required minimum wire size.

The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension

cord to make up the total length, be sure each cord

contains at least the minimum wire size required. If

you are using one extension cord for more than one

tool, add the nameplate amperes and use the sum

to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be

sure it is marked with the suffi x “W-A” (“W” in

Canada) to indicate that it is acceptable for outdoor

use.

• Be sure your extension cord is properly wired

and in good electrical condition. Always replace a

damaged extension cord or have it repaired by a

qualifi ed person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

Recommended Minimum Wire Gauge

for Extension Cords*

Extension Cord Length

* Based on limiting the line voltage drop to fi ve volts

at 150% of the rated amperes.

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

25'

18

18

18

18

16

14

12

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

50'

18

18

18

16

14

12

10

EXTENSION CORDS

WARNING

To reduce the risk of injury,

always use a side handle when using

this tool. Always brace or hold securely.

ASSEMBLY

WARNING

To reduce the risk of injury,

always unplug tool before attaching

or removing accessories or making adjust-

ments. Use only specifi cally recommended

accessories. Others may be hazardous.

Adjusting the Side Handle Position

1. Loosen the side handle by unscrewing the side

handle grip until the side handle rotates freely.

2. Rotate the side handle to the desired position.

3. Tighten the side handle grip securely.

OPERATION

WARNING

To reduce the risk of injury,

always unplug tool before attaching

or removing accessories or making adjust-

ments. Use only specifi cally recommended

accessories. Others may be hazardous.

WARNING

To reduce the risk of injury,

keep hands and cord away from the

bit and all moving parts.

WARNING

To reduce the risk of injury

do not grasp the bit while the chuck is rotat-

ing or while the bit is falling from the chuck.

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with

side shields.

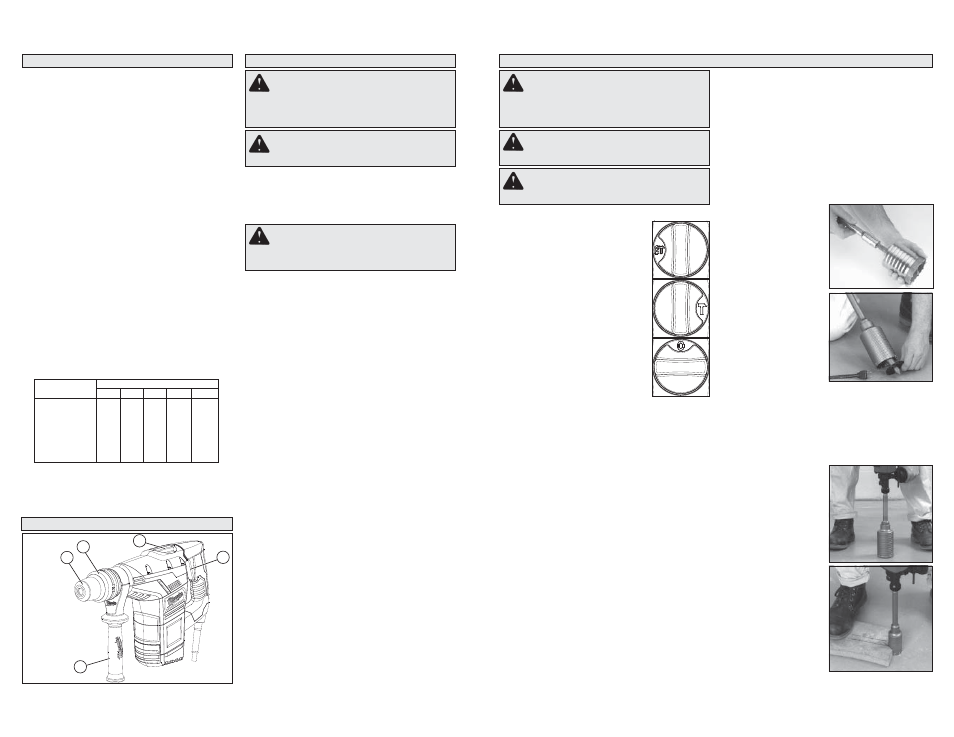

FUNCTIONAL DESCRIPTION

1. Side handle

2. Bit holder

3. Bit release collar

4. Mode selector

knob

5. Trigger

Installing Bits and Chisels

Be sure that the shank of the bit is clean. Dirt par-

ticles may cause the bit to line up improperly. Do not

use bits larger than the maximum recommended

capacity of the drill because gear damage or mo-

tor overloading may result. For best performance,

be sure that the bit is properly sharpened and the

shank is lightly greased before use. Use caution

when handling hot bits and chisels.

SDS-Max Drive System

1. Unplug tool.

2. Insert the bit or chisel into the nose of the tool.

3. Push bit into tool until it locks.

5. Check to see that the bit is locked by tugging on it.

6. To remove bits and chisels, pull back on the bit

release collar and remove bit.

Spline Drive System

1. Unplug tool.

2. Insert the bit or chisel into the nose of the tool.

If you are using a rotary bit, make sure that the

splines on the shank engage with the splines

inside the nose of the tool.

If you are using a chisel, make sure that the notch

in the shank faces up.

3. Push bit into tool until it locks.

4. Check to see that the bit is locked by tugging on it.

5. To remove bits and chisels, pull bit release collar

toward the rear of tool and remove bit.

Selecting Action

T h e s e M I L W A U K E E R o t a r y

Hammers have three settings:

hammering with rotation, hammering-

only, and chisel adjustment.

1. Hammering with rotation. Use

this setting for drilling holes with

drill bits.

2. Hammering only. For use with

“hammering-only” accessories.

Use this setting for chiseling or

setting self-drilling anchors.

3. Chisel adjustment. Use this set-

ting to adjust the angle of the chisel

blade in relation to the tool. With a

chisel mounted in the tool:

• turn the knob to this setting

• rotate the chisel to the desired

angle

• turn the knob to "hammering-only".

NOTE: To engage the hammering mechanism,

maintain pressure on the bit. When the pressure

on the bit is released, the hammering will stop.

Starting and Stopping

1. To start the tool, grasp the handle fi rmly and pull

the trigger.

2. To stop the tool, release the trigger. Make sure

the tool comes to a complete stop before laying

the tool down.

Operating

Position the tool, grasp the handles fi rmly and pull

the trigger. Always hold the tool securely using both

handles to maintain control. This tool has been

designed to achieve top performance with only

moderate pressure. Let the tool do the work.

If the speed begins to drop off when drilling large

or deep holes, pull the bit partially out of the hole

while the tool is running to help clear dust. Do not

use water to settle the dust since it will clog the bit

fl utes and tend to make the bit bind in the hole. If

the bit should bind, a built-in, non-adjustable slip

clutch prevents the bit from turning. If this occurs,

stop the tool, free the bit and begin again.

Cold Starting

If this tool is stored for a long period of time or

at cold temperatures, it may not hammer ini-

tially because the lubrication has become stiff.

To warm up the tool:

2

1

4

5

1. Insert and lock a bit or chisel into the tool.

2. Pull the trigger and apply force to the bit or chisel

against a concrete or wood surface for a few

seconds. Release the trigger

3. Repeat until the tool starts hammering. The

colder the tool is, the longer it will take to warm

up.

Using Rotary Percussion Core Bits

Core Bits are useful for drilling large or long holes

in concrete. MILWAUKEE Heavy-Duty Core Bits

have heat-treated steel bodies with durable carbide

tips. These core bits are specially designed for fast,

accurate drilling with combined hammering and

rotary action.

1. Clean and lubricate the

threads on the adapter

and core bit to make

later removal easier.

Thread the adapter

shank to the rear of the

core bit.

2. Push the guide plate

onto the pointed end

of the center pin. In-

sert the center pin and

guide plate assembly

into the core bit. Be

sure the small end of

the center pin is se-

curely placed into the

hole in the center of the

core bit.

For LHS systems, screw the threaded end of the

centering bit into the core bit.

NOTE: If using an extension, fi rst thread the

adapter shank to the extension. Then thread the

core bit to the extension.

3. Insert the adapter into the nose of the tool as

described in “Installing Bits and Chisels”. Set the

knob to the "hammering with rotation" setting.

4. Press the centering

bit fi rmly against your

center mark, hold the

tool fi rmly and pull the

trigger.

NOTE: If the 48-20-

5099 threaded stud is

used, or a center pin

and guide plate are not

available, use a tem-

plate or notched board

to start the hole.

5. Start the tool. After drill-

ing to about the depth

of the core bit teeth,

remove the center pin

and guide plate from

the core bit (not nec-

esary for LHS system).

Resume drilling.

3