Milwaukee Tool 5268-21 User Manual

Page 4

6

7

Cut

approximately

1/4" deep with

a core bit.

Side view

of slab

Pull bit out as far

as possible once

or twice per inch

drilled.

Drill a hole

through the

work.

Dust and debris

will fall through

the hole.

Top view

NOTE: If the 48-20-

5099 threaded stud is

used, or a center pin

and guide plate are

not available, use a

template or notched

board to start the hole.

5. Start the tool. After drill-

ing to about the depth

of the core bit teeth,

remove the center pin

and guide plate from

the core bit (not necesary for LHS system). Re-

sume drilling.

6. To change the core bit, hold the tool upwards,

pointing it away from your body, and run it briefl y

in forward to loosen the core bit from the adapter.

NOTE: To make deeper holes, remove the core bit,

break and remove the core, then resume drilling.

When drilling long or deep holes, after each inch

of penetration pull the bit partially out of the hole

while the tool is running, to help clear dust from the

bit fl utes. Dust can clog the bit fl utes and can make

the bit bind in the hole. If this occurs, stop the tool,

free the bit and begin again.

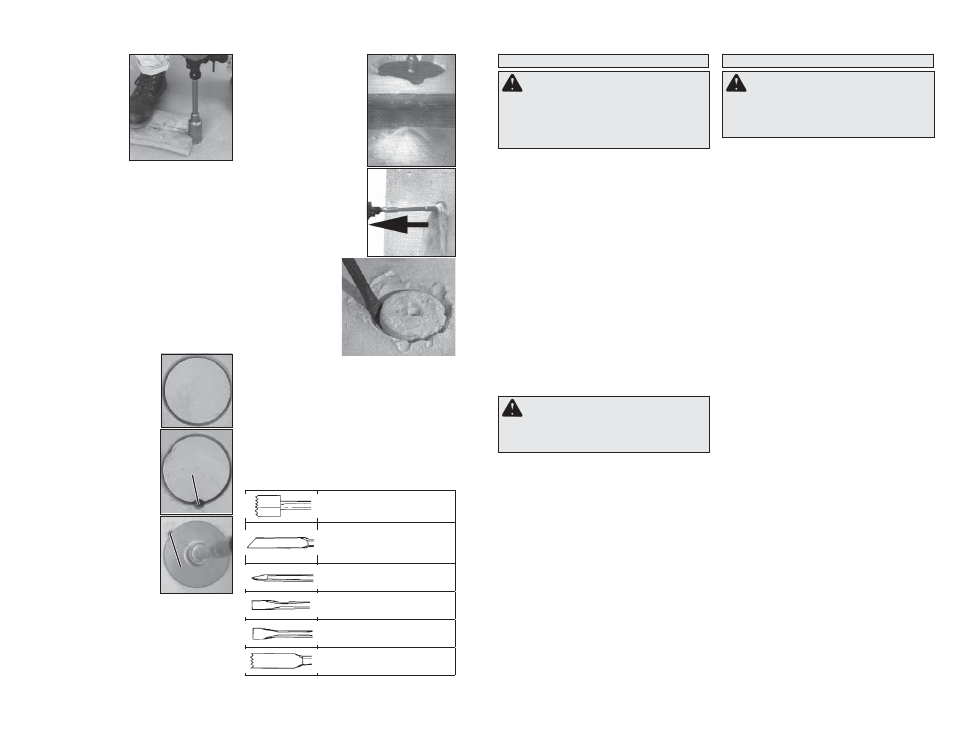

Drilling Large Diameter Holes with Core Bits

When drilling holes with large diameter core bits,

dust may build up in the cut and can cause the tool

to stall, bind, or cut slowly. By creating an opening

for the dust to escape, drilling time, bit stress, and

tool stress can be reduced.

1. Start the cut as normal.

2. Once the bit is fi rmly estab-

lished in the cut (about 1/4"

deep), remove the bit from the

cut.

3. Remove the bit from the tool.

4. Install a standard fluted bit,

approximately 7/8" in diameter,

onto the tool.

5. Drill a perpendicular hole

through the kerf of the large

hole.

• Depending on the location of

the work, the hole should either

break through the other side of

the hole/fl oor or extend 4"-5"

past the end of the workpiece

(such as into the dirt below a

concrete slab).

• If dust builds up in the hole,

vacuum it out and continue

drilling.

Chiseling and Chipping

MILWAUKEE Rotary Hammers may be used for

chipping and chiseling.

When chiseling, hold the tool at an angle to the

workpiece. Work from a corner or close to the edge

of the workpiece, breaking off one small area at a

time rather than attempting too large an area.

A variety of accessories are available.

• If drilling through a wall,

the hole for dust should

be drilled on the lowest

part of the large hole kerf

as the dust will fall there

when drilling and can be

evacuated more easily.

6. Reinstall the core bit and

continue drilling. Dust and

debris will fall through the

hole and optimize the cut-

ting ability of the bit.

NOTE: If unable to drill a hole

in the kerf, pull back on the

bit with the hammer running.

This will remove some of the

dust and debris from the cut.

Repeat this for every inch of

drilling. If necessary, vacuum

dust and debris from the cut

and surrounding area.

7. For core bits, once

the maximum core

bit depth is drilled,

the core must be

b r o k e n a n d r e -

moved.

• Install a chisel bit.

• Place the chisel into

the hole kerf.

• Chisel down into

the kerf at several

points until the core is loose or broken.

• Remove the core and vacuum/remove any

remaining dust and debris.

• Install the core bit and continue the cut.

Bushing Tools

Used to surface concrete.

Mortar Cutting Chisels

(Seam Tools)

For removing old mortar for tuck

pointing or caulking.

Bull Points

For demolition work and starting

holes in concrete slabs.

Flat Chisels

For edging, chipping or channeling.

Scaling Chisels

For removing weld spatter or scale

and cutting straight lines.

Slotting Chisel

For slotting and cutting between

drilled holes in concrete and masonry.

ACCESSORIES

WARNING

To reduce the risk of injury,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

MAINTENANCE

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, bro-

ken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

WARNING

To reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the tool

or try to do any rewiring on the tool’s electrical

system. Contact a MILWAUKEE service facility

for ALL repairs.

WARNING

To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.