Using sanding discs – Milwaukee Tool 6088-30 User Manual

Page 9

9

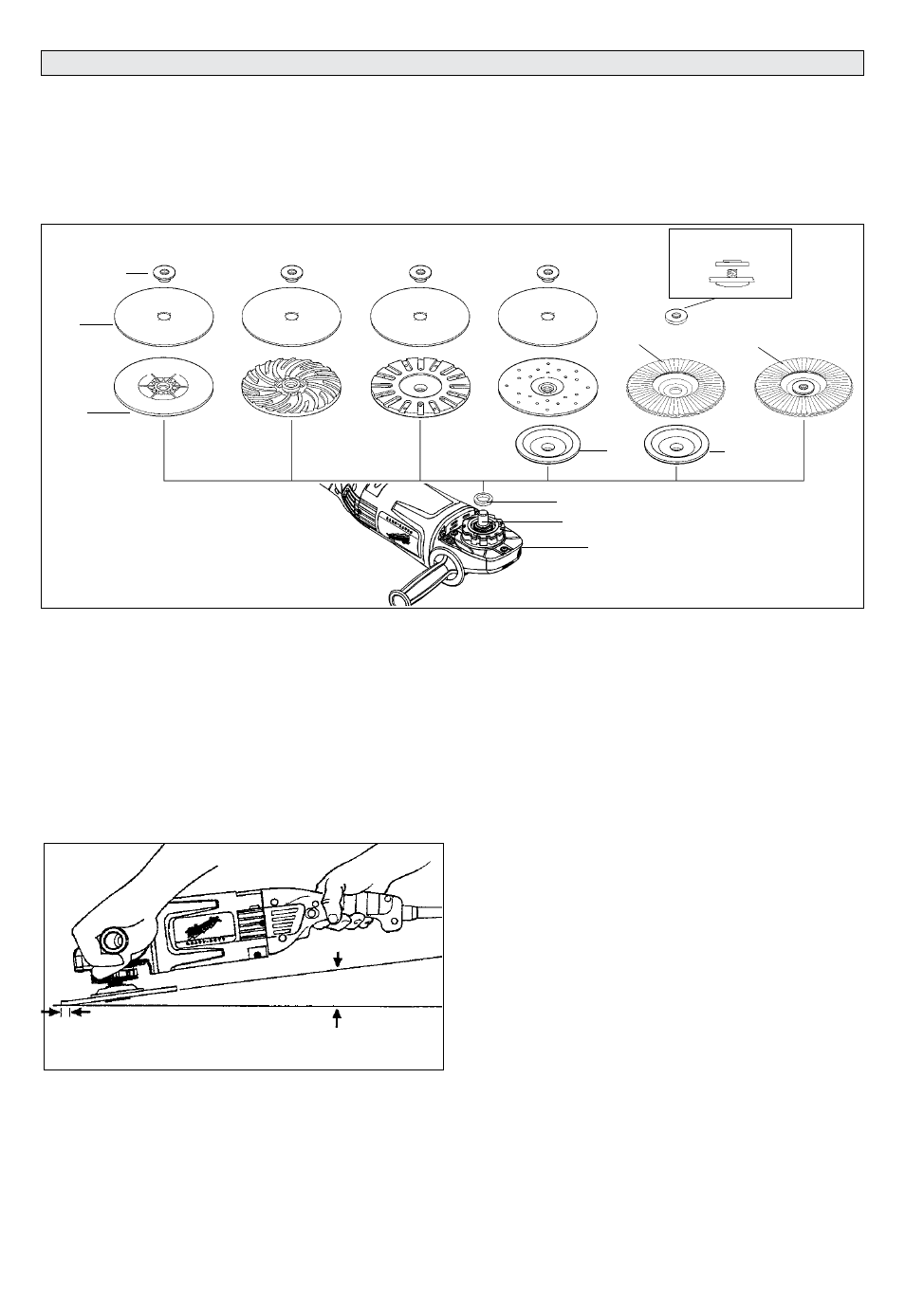

Installing Sanding Discs

1. Unplug tool and place it upside down on a level

surface as shown. Remove any accessories from

spindle.

2. Thread nylon washer onto spindle. Attach

backing pad and sanding disc using Fig. 6

to determine type and order of assembly.

Fig. 6

Spindle lock button

Spindle

Backing

pads

A. Polypropylene

B. Spiral

C. Rubber

D. Phenolic

Disc nut

Sanding

disc

Nylon washer

Rubber

pad

Type 27

flange

Flap disk

Flap disk with hub

B

C

D

A

Disc nut position

using sanding discs

NOTE: When installing flap disc without hub,

position disc nut as shown.

3. To tighten, press the spindle lock button while

turning disc nut clockwise.

4. To remove sanding disc and backing pad, unplug

tool and reverse procedure.

Removing Welds or Hammer Marks

When removing welds or hammer marks, limit

coarse sanding to the immediate area. Use suc-

cessively finer grits to smooth surface.

Cross Sanding

When finishing a surface that has been pre-

pared by a coarse disc or wheel, sand at right

3. Use long, sweeping, side to side strokes, advanc-

ing forward to produce the desired finish.

Sanding

1. Use a clamp, vise or other practical means to

hold your work, freeing both hands to control your

tool. Firmly grasp rear handle and side handle

before starting and while tool is in operation.

Allow sanding disc to come to full speed before

beginning to sand.

2. Hold tool at 5° to 15° angle as shown to ensure

proper sanding pressure and control (Fig. 7). Too

great an angle will result in too much pressure

and could cause excessive wear to the disc and

workpiece. Too small an angle will reduce control.

Hold at a 5° to 15° angle

Fig. 7

For best results use only

this portion of disc

angles to the strokes made by the coarser disc.

Finishing marks left from previous sanding are eas-

ily seen and removed for a uniform finish. Failure

to cross sand when changing from a coarse disc to

a finishing disc may result in deep scratches and

circular marks.

Selecting Sanding Discs & Grit

Refer to the table below to select the correct type

of sanding disc for your job. Generally, use 16, 24

or 36 grit for heavy stock removal; 50, 60 or 80 grit

for medium stock removal and 120 grit for finishing.

Always begin with a coarse grit, using successively

finer grits to obtain the desired finish. See Catalog

for a complete list of MILWAUKEE sanding discs.

Finishing Metal

Constantly move across the surface. Work faster on

curved surfaces where contact areas are smaller

and pressure is greater. Flat areas may appear at

the end of the stroke when pressure is too heavy.

Ease up on pressure at end of each stroke and

when reversing strokes.

Troubleshooting

Deep scratches and circular marks can result from:

• Using too coarse a grit

• Using a partially glazed disc

• Dirt or loose metal on the workpiece

• Failure to sand across the grain when changing

from coarse to finishing discs

Bluish discoloration of metal surface indicates:

• Excessive heat caused by circular motion in a

small area

• Excessive pressure

• Use of worn out or glazed discs