Lippert Components Trailer Axle (8-12K) User Manual

Page 16

Rev: 04.18.2014

Page 16

Trailer Axle 8-12K Owners Manual FULL

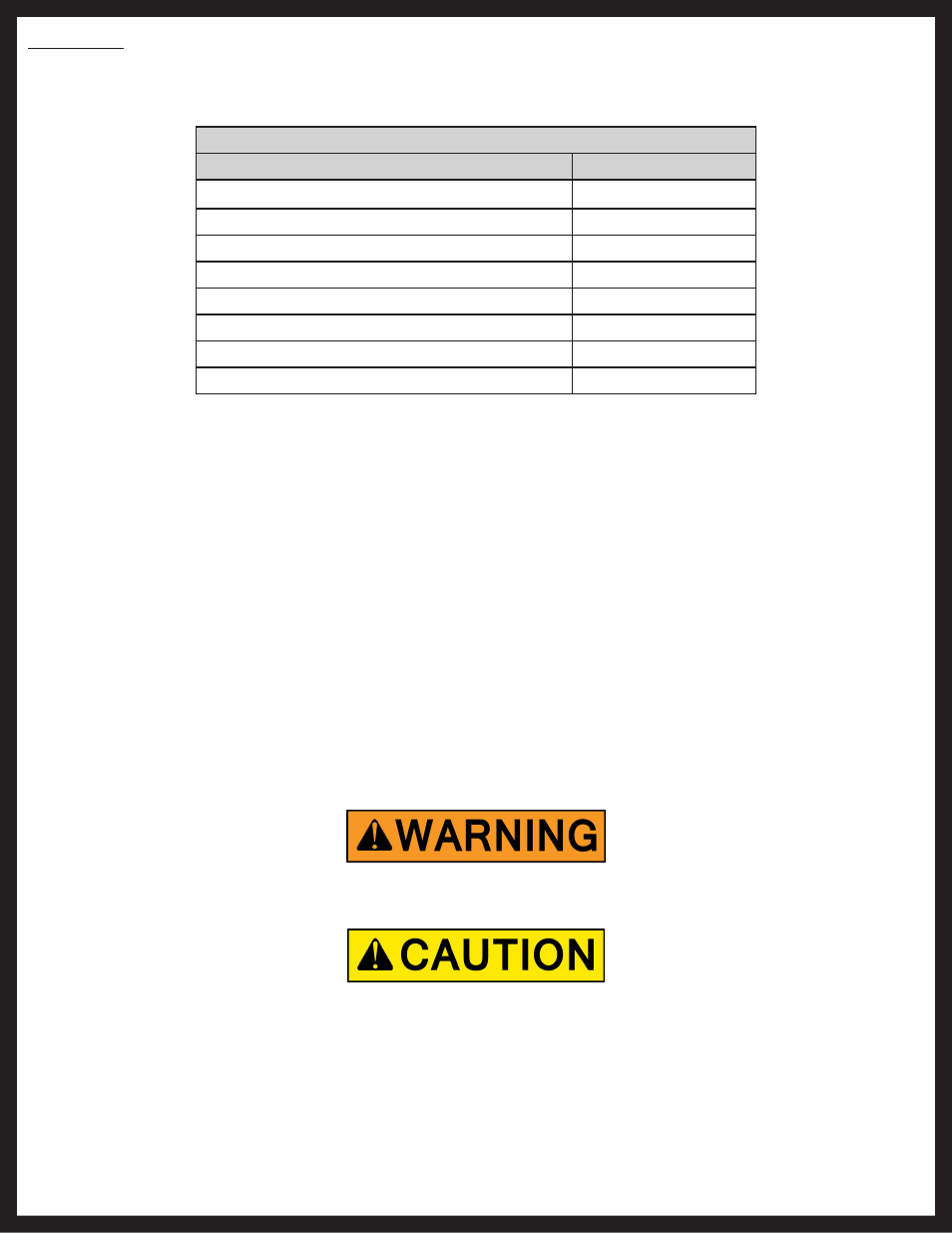

Equalizer and Spring Eye Nut Torque Specifications

Bolt Type

Torque

9/16" 8K U-Bolt Nuts

90 ft-lbs

5/8" 10K U-Bolt Nuts

95 ft-lbs

5/8" 12K U-Bolt Nuts

115 ft-lbs

9/16" Shoulder Bolts

35 ft-lbs

9/16" Non-Shoulder Bolts

Snug

10K and 12K Spring Eye Bolt

200 ft-lbs

10K and 12K Center Hanger/Equalizer Bolt

300 ft-lbs

Keeper Bolt

Snug

Inspection

All the components of your suspension system should be visually inspected for signs of wear, damage or

loose fasteners at least every 6,000 miles. When replacing or tightening loose fasteners, consult the torque

specs below for correct torque values.

Worn spring eye bushings or sagging or broken springs should be replaced using the following method:

1. Support the trailer with the wheels just off the ground. Follow the trailer manufacturer’s

recommendations for lifting and supporting the unit.

2. After the unit is properly supported, place a suitable block under the axle tube near the end to be

repaired. This block is to support the weight of the axle only so that suspension components can be

serviced or replaced.

3. Disassemble the U-bolts, nuts, and tie plates.

4. Remove the spring eye bolts and the spring.

5. If the spring eye bushings are to be replaced, press out the old bushing by hand or tapping out with a

punch.

6. Free-floating nylon bushing needs no lubrication. Press the new bushing into the spring eye by hand

or gently tapping it in with a bounceless rubber or plastic mallet.

7. Reinstall repaired or replaced components in reverse order.

NOTE: For multiple axle units, the weight of each axle must be supported as outlined in Step 2 before

disassembly of any component of the suspension system.

Lift unit by the frame and never the axle or suspension. Do not go under unit unless it is properly

supported by jack stands. Unsupported units can fall causing death or serious injury.

Always wear eye protection when servicing the axle, brakes, hubs, springs and wheels. Failure to wear

eye protection may result in serious injury.

If the equalizer or equalizer bushings must be replaced, follow the instructions above for lifting and

supporting the trailer unit and then proceed as follows:

1. With both axles blocked up, remove the spring eyebolt, keeper bolt, and equalizer bolt from the

equalizer to be repaired or replaced.

2. Press the old nylon bushing out of the equalizer.

3. Reassemble in reverse order.