Installation, Operation, Maintenance – Leslie Controls AFG-2, etc small flow airmate pressure reducing valve and air loader User Manual

Page 3

3

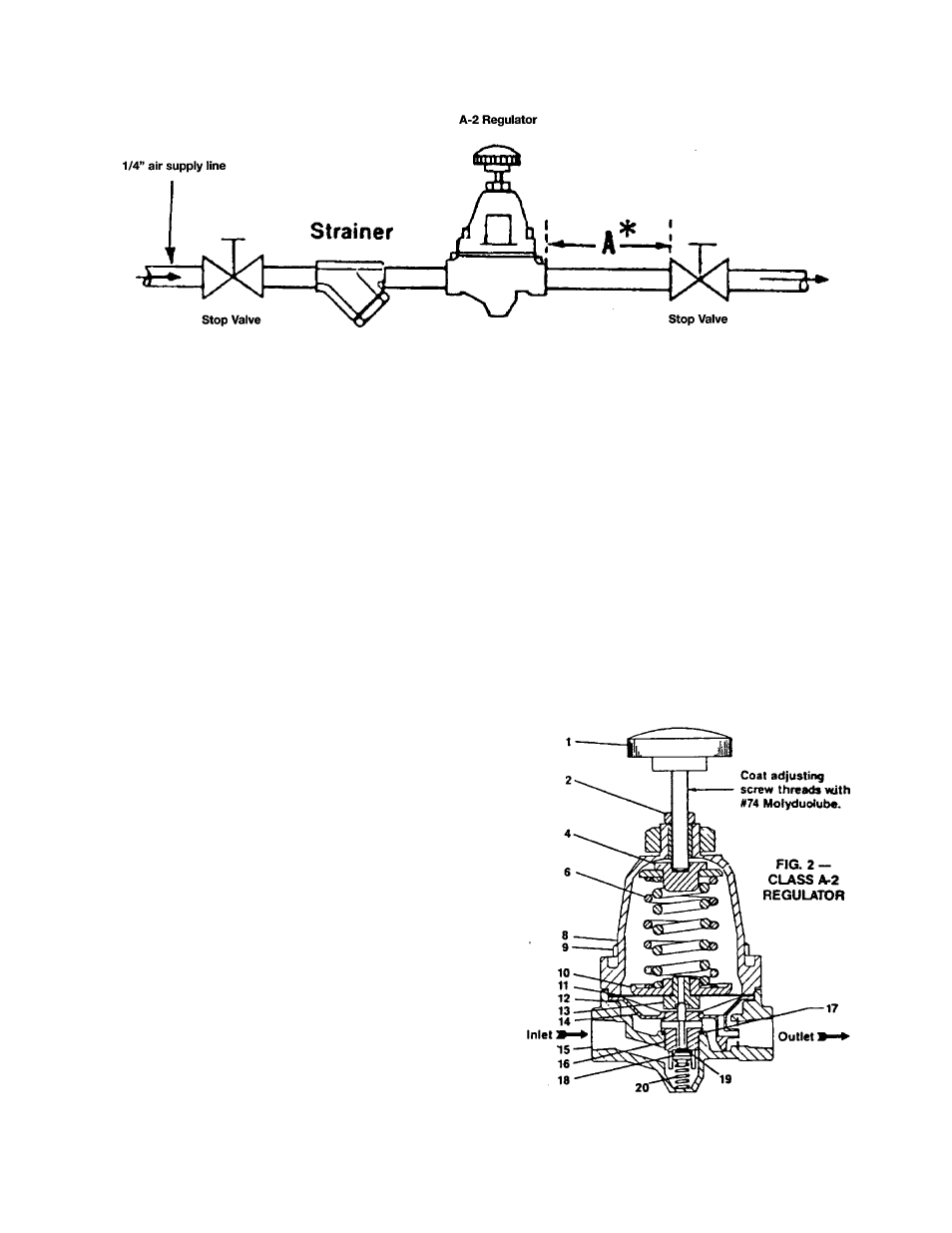

Figure 1 - Installation Detail

INSTALLATION

Install as shown in Fig. 1. Use non-corrosive fittings and

piping throughout. Use fine wire mesh or poromet filter

screen.

Note: Strainer, shown for Class A-2 Types, is not

necessary for Filter Type Classes, AF-2.

*

When used with air motors or pulsating equipment,

line “A” should be of a sufficient length and diameter

to provide a reservoir. On close coupled installations

install small reservoir.

OPERATION

1. Open inlet supply valve to regulator.

Note: Supply pressure should be at least 5 PSIG above

maximum controlled pressure desired.

2. Open outlet stop valve partially.

3. Turn handwheel (1) clockwise to start flow through

regulator. Adjust for desired controlled pressure.**

Tighten locknut (2). Open outlet to stop valve fully.

** Turn handwheel clockwise to increase controlled

pressure; counterclockwise to decrease.

MAINTENANCE

DISMANTLING

1.

Shut-off air supply. Loosen locknut (2). Relieve all

adjusting spring compression.

2.

Disassemble adjusting spring case (8), top spring seat

(4), adjusting spring(s) (6) and nozzle-diaphragm

assembly from main body.

3.

Grasp internal rib of aspirator plate (14) (marked “Lift

Here”) and lift out of main body. Remove gasket (12).

4.

Unscrew valve seat (16) with “O” Ring (17) from

main body. Lift out main valve (18), with “O” Ring

(19), and main valve spring (20).

Figure 2 - Class A-2 Regulator