LAARS HWG-M2-250 - Installation, Operation and Maintenance Instructions User Manual

Page 7

9600 HWG Water Heater

Page 7

Cold water supply piping, fittings and accessories.

1.

Install a strainer between the 9600 HWG and the

system. For proper pipe size and distance

limitations, refer to Table 3.

2.

Connect a drain valve and a shut off valve to the

9600 HWG cold inlet. On multiple units install a

check valve at each unit’s cold water inlet.

3.

Where check valves have been installed on cold

water inlet piping, check to be sure system has

an adequately sized expansion tank to allow

thermal expansion to occur.

Hot water supply piping.

Follow the manufacturer’s guidelines for

completion of the hot water system connections.

NOTE: A listed temperature and pressure

relief valve listed as complying with the Standard

for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, 1). ANSI

Z21.22 latest edition, or 2). CAN / CGA 1 - 4.4, of

suitable discharge capacity must be installed in the

separate storage tank system.

3.4 Tank Temperature Control

The 9600 HWG is turned on and off by a remote

tank aquastat. Locate the aquastat above the cold

water inlet fitting in the separate storage tank. The

9600 HWG draws water off the bottom of the tank

and pumps hot water back into the tank. When the hot

water level reaches the level of the aquastat, the

aquastat switch will open and turn off the 9600 HWG.

Please contact your factory representative if you

have any questions about storage tank application.

If a water heater is installed in a closed water

supply system, such as one having a backflow

preventer in a cold water supply line, means shall be

provided to control thermal expansion, such as a

properly sized potable water expansion tank.

If the relief valve on the appliance discharges

periodically, this may be due to thermal expansion in

Table 3. Water pipe and tube sizing between unit and tank.

Note: This unit must be installed in a pressurized closed

system that maintains a minimum of 10 psi static pressure.

* If water hardness is greater than 10 grains, a water soft-

ening or particle suspension device must be installed be-

fore the heater, or warranty will be void.

Copper tube or

pipe size

Maximum

allowable tubing

length

Amount

deducted for

each additional

90° elbow

Amount

deducted for

each additional

45° elbow

1¼"

40'

2'

1½'

1½"

120'

2'

1½'

2"

270'

2'

1½'

a closed water supply system. Contact the water

supplier or local plumbing inspector on how to correct

this situation. Do not plug the relief valve.

No valves shall be placed between the tank T &

P relief valve and the tank. Pipe the outlet from the

relief valve such that any discharge from the relief

valve will be conducted to a suitable place for

disposal when relief occurs. Do not reduce line size or

install any valves in this line. The line must be

installed to allow complete drainage of both the valve

and the line.

3.5 Condensate Drain Connection

A black plastic fitting (labeled CONDENSATE)

is located on the side of the cabinet. This fitting will

accept 1/2" OD plastic tubing.

1.

Connect a plastic tube between the fitting and

the floor drain or condensate pump if a floor

drain is not accessible.

NOTE: Connecting tubing must run

DOWNWARDS from the level of the fitting. See

Figure 8.

2.

Above the fitting is a hole in the cabinet. Behind

this hole is a 1/2" OD tube which serves as a

condensate relief if the lower drain becomes

blocked (see Figure 9).

3.

Run this condensate relief tube through the hole

in cabinet and to a drain pan. DO NOT pipe in

common with condensate drain fitted in A

above.

3.6 Electrical Connections

All electrical wiring must conform to local codes

and/or the 1). National Electrical Code ANSI/NFPA

No. 70-Latest Edition, or 2). The CSA Standard C22.1

“Canadian Electrical Code - Part 1”.

Single pole switches, including those of safety

controls and protective devices must not be wired in a

grounded line.

All electrical connections are made in the field

wiring box which is located on the left side of the

unit.

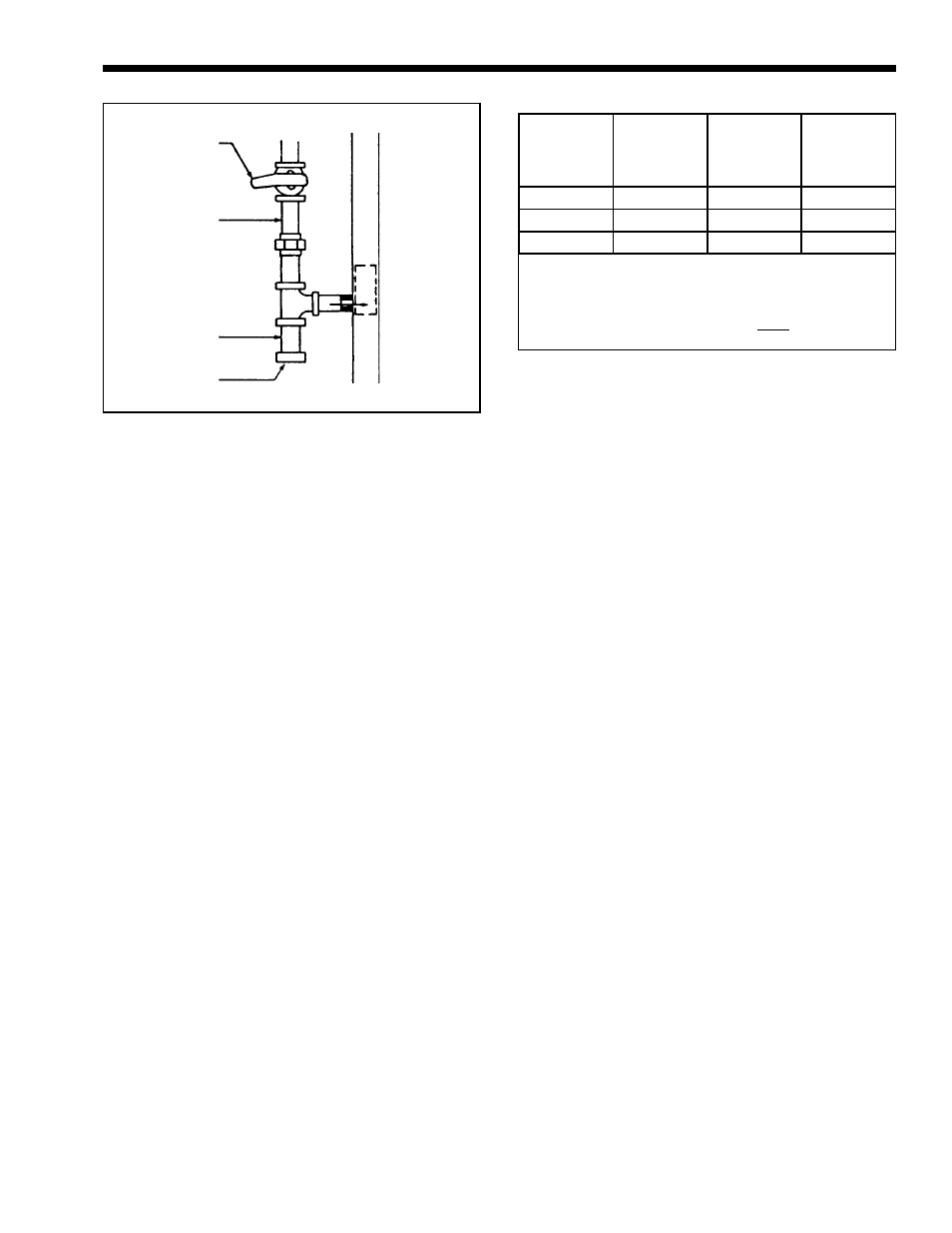

Figure 5. Gas supply piping.

To

9600 HWG

Manual Main

Shut Off

Gas Supply

Drip Leg

Cap