LAARS Mini-Therm JVS (Sizes 50-225) - Users Manual User Manual

Page 4

Page 4

LAARS HEATING SYSTEMS

D. Air Shutter Adjustment

(when required)

1. STOP! Read the safety information on the last page.

2. Perform a System Start-Up in accordance with

Section A of this manual.

3. Remove the burner cover by loosening the two

thumbscrews.

4. Observe the flame pattern on all burners. If the

flame on any burner is pulsing, unstable or lifting

continue with this procedure. Otherwise skip to

step 10.

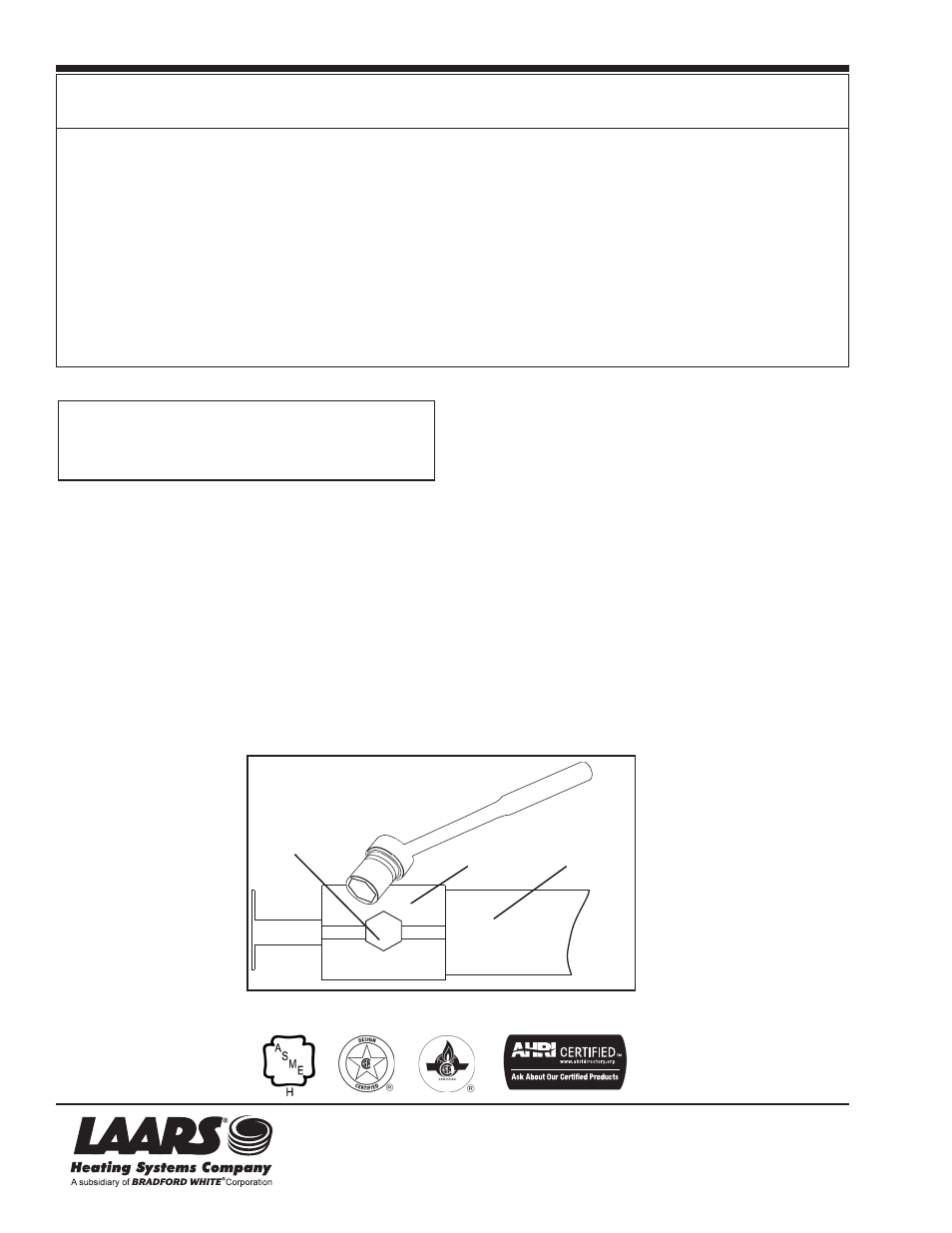

5. On all burners exhibiting an abnormal flame, loosen

but do not remove the air shutter locking screw

using a 5/16 inch wrench. (See Fig. 5 below.)

6. On each affected burner, slowly close the air

shutter until a normal flame is observed, then re-

tighten its associated locking screw.

7. Turn the boiler off.

8. Perform a System Start-Up in accordance with

Section A of this manual.

9. Observe the flame pattern on all burners. If

the flame on any burner is pulsing, unstable or

lifting, repeat steps 5 and 6 until all burners are

exhibiting a normal flame.

10. Re-install the burner cover and tighten it in place.

LOCKING SCREW

(5/16" HEAD)

AIR SHUTTER BURNER

Boiler

Type of

Valve

Model

Size

Suffix*

Gas

Part No.

Mfr. No.

Manufacturer

JVS

50-75

D

NAT

V0077400

VR8304H

HONEYWELL

JVS

100-225

K

NAT

V0079000

VR8304H

HONEYWELL

JVS

50-75

D

LP

V0077500

VR8304H

HONEYWELL

JVS

100-225

K

LP

V0079100

VR8304H

HONEYWELL

JVH

50-160

C

NAT

V2001800

SV9501H

HONEYWELL

JVH

225

C

NAT

V2001900

SV9601H

HONEYWELL

JVH

50-225

C

LP

V2002300

SV9501H

HONEYWELL

*Suffix Definitions

C = On/Off Firing

D = On/Off Firing

K = Two-Stage Firing

Figure 5 - Removing the Air Shutter Locking Screw

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1355 Kuehner Drive, Simi Valley, CA 93063 • 800.900.9276 • Fax 800.559.1583 (Sales, Service)

1869 Sismet Rd., Mississauga, Ontario, Canada LHW 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Printed in U.S.A. © Laars Heating Systems 1212 1026w

Table 1 - Gas Control Valves

Note: The warranty does not cover any damage

caused by lack of required maintenance or

improper operating procedures.

H2355700A