LAARS Mini-Therm JVS (Sizes 50-225) - Users Manual User Manual

Page 2

Page 2

LAARS Heating Systems

Important: When lighting or relighting, wait the

full 5 minutes specified in the lighting instructions.

Unburned gases can accumulate in the fire box and

may flash back. Allow ample time for natural air

movement to clear the gases from the chamber before

lighting or relighting.

Relighting - All Models:

1. Turn off electrical power to the boiler.

2. Turn the gas valve knob (clockwise for JVS) to

Off.

3. Wait five minutes.

4. Turn the gas valve knob (counterclockwise for

JVS) to On.

5. Restore power to the boiler, and set the

thermostat to the desired temperature. The

pilot will automatically ignite when there is

a call for heat.

Circulator Pump:

In normal operation, the pump is energized by the wall

thermostat via the pump relay supplied with the boiler.

Caution: Hazard of electrical shock!

Disconnect power to the boiler before

servicing the relay or transformer.

B. System Shut Down

Turn off all gas valves and the electrical

disconnect switch. Whenever danger of freezing exists,

shut off the water supply, remove the drain plugs in the

left side of the heater and open the drain valve on the

right side. Drain every part of the system which might

be subject to freezing temperatures.

Should overheating occur or the gas supply fail

to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at

a location external to the appliance.

En cas de surchauffe ou si l'admission de gas

ne peut être coupée, ne pas couper ni débrancher

l'alimentation électrique de la pompe. Fermer plutôt le

robinet d'admission de gas à l'extérieur de l'appareil.

To Shut Down Boiler:

(JVS and JVH) Automatic Ignition Systems:

1. Turn off power to the boiler and set the

thermostat to the lowest setting.

2. Turn the gas valve knob (clockwise for JVS) or

switch to the Off position.

C. Maintenance

1. Lubricate the water circulating pump according

to the instructions found on the pump.

2. If a strainer is employed in a pressure reducing

valve or in the piping, clean it every six months.

3. At start-up and periodically thereafter, the flame

should be observed for proper performance. If

the flame has “sooting” tips, check for debris

near the orifices. If this continues, call a service

technician.

4. For JVS models, ensure proper operation of the

mechanical damper, mounted in the flue collar,

by observing the damper handle. Be sure the

handle swings when the draft inducer starts.

Depending on the boiler size, the swing may be

as little as 30°. Remove any obstructions and

clean around the pivot rod (handle) holes.

5. Inspect the venting system for obstructions,

leakage and corrosion at least once each year.

6. Keep the boiler area clear and free from

combustible material, gasoline and other

flammable vapors and liquids.

7. Be certain all combustion air and ventilation

openings are unobstructed.

8. Check for fouling on the external surfaces of the

heat exchanger every six months.

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion

and is a sign of combustion air and/or venting

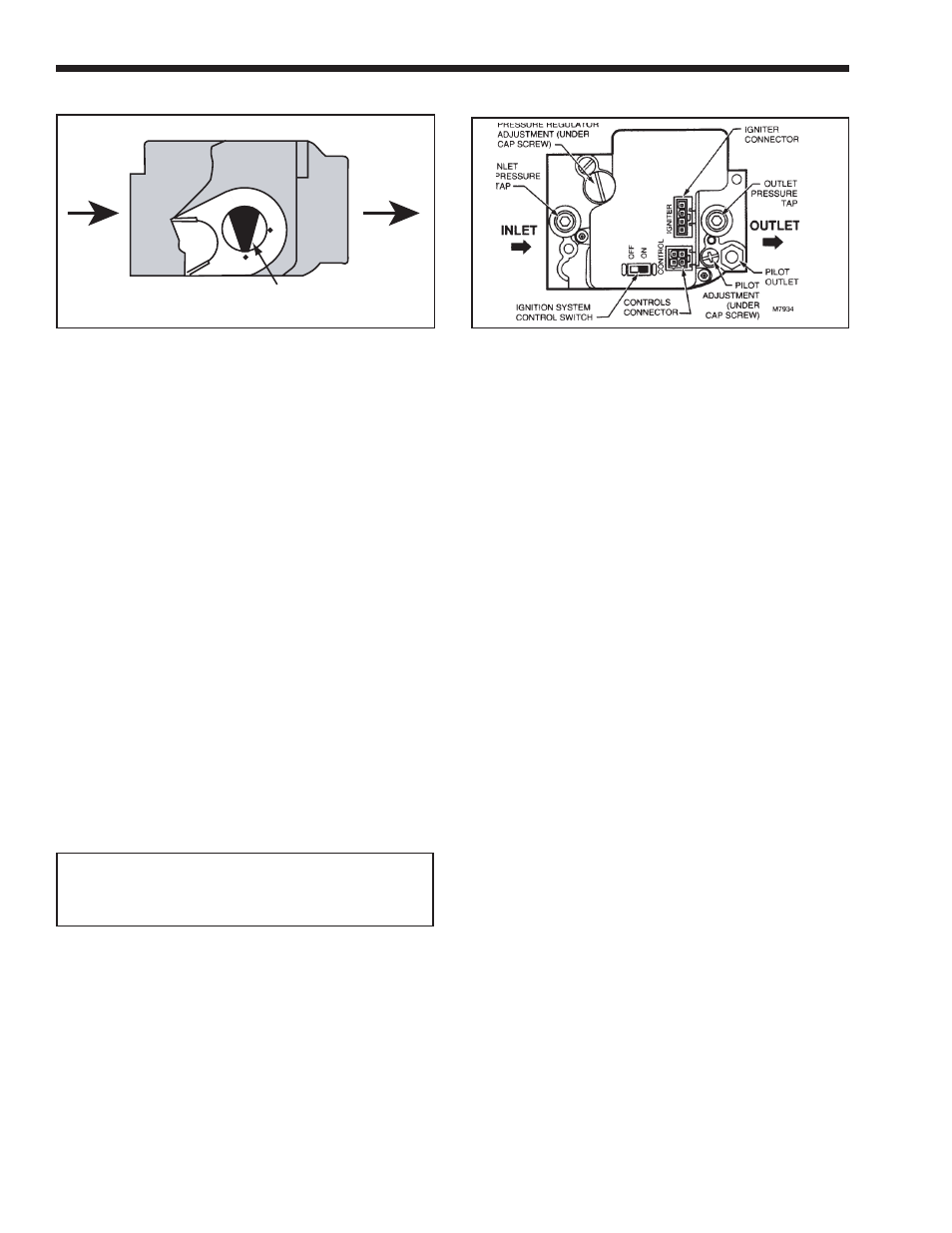

Figure 2 - Gas Control for JVH Models

ON

OFF

Gas Control Knob

Figure 1 - Gas Control for Automatic Ignition System (JVS)