LAARS Mighty Venter MV2 (Sizes 175-400) - Install and Operating Manual User Manual

Page 6

Page 6

LAARS Heating Systems

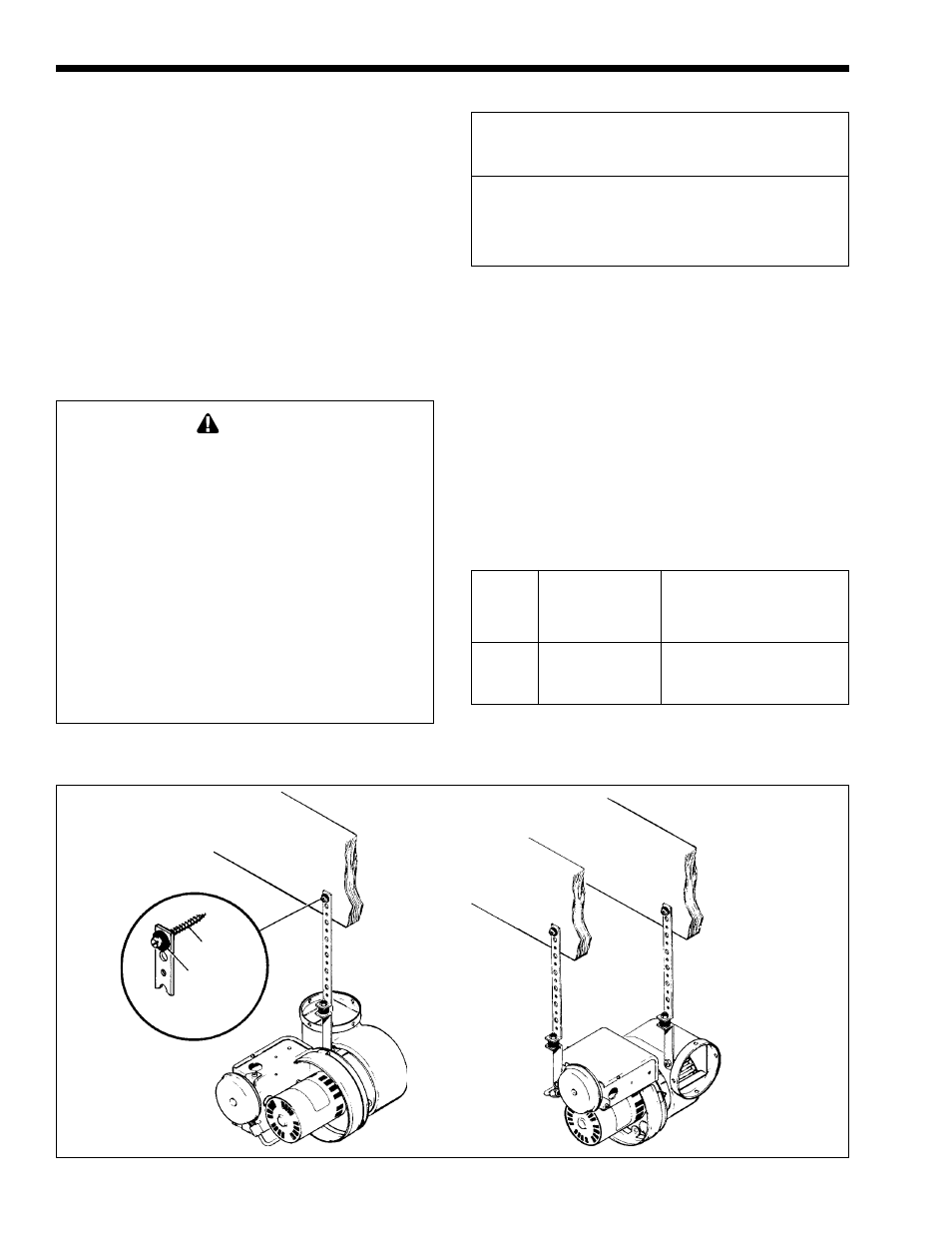

Figure 3. Power Venter Discharge Options.

To facilitate installation and reduce vibration, 2

mounting brackets, 2 rubber isolators, and 2 rubber

grommets are included. One of the brackets can be

used as a temporary “third hand” while positioning it

for permanent installation (see Figure 3).

When installing the Power Venter for horizontal

discharge, install one of the brackets to the electrical

box using the nut/screw provided. Install the other to

the damper rod. When installing the Power Venter for

vertical discharge, only one bracket is needed. Mount

this bracket to the motor as shown in Figure 3.

SECTION 3.

Electrical Wiring

WARNING

All wiring from the Power Venter to the appliance

must comply with local codes, or in their absence,

the National Electric Code (NFPA #70) in the United

States and/or CSA C22.1 Electrical Code in

Canada.

Disconnect 115 VAC power to the appliance before

proceeding with wiring the Power Venter. The power

can be disconnected by tripping the circuit breaker

or removing the fuse protecting the appliance.

All wiring must comply with applicable codes and

ordinances. All 115 VAC wiring must be rigid or

semi-rigid metal conduit with 18 AWG, 300 VAC,

90° C rated copper wire.

Wire the hot water boiler and the Power Venter

exactly as shown in Figure 7 and follow these steps:

1. Connect the black and white (115 VAC) wires

from the Power Venter to the boiler control box as

shown in Figure 7.

2. Connect the red, blue and yellow (24 VAC)

wires to the terminal block as shown in Figure 7.

Make sure the current capacities of the wires,

switches, etc. at 115 VAC meet the ratings in Table 3.

3. Remove factory-installed jumper from

between boiler terminals 3 and 4.

Equivalent Full Load

Power Venter

Currents

Model

Motor HP

(Amps - 115 VAC)

MV1

1/25

1.3

MV2

1/8

4.4

Table 3. Electrical Ratings.

Boiler

Vent

Vent

Fig. Boiler Draft Hood Pipe

Hood

Rough-in

No.

Size

Outlet

Dia.

Dia.

Dim.

4

175

6"

4"

4"

8.0" Dia.

5

250

7"

6"

6"

9.0" Dia.

6

325

8"

6"

6"

9.0" Dia.

6

400

9"

6"

6"

9.0" Dia.

Table 2.