1b. vent sizing, 1c. inspection and unpacking, 1d. installer information – LAARS Mighty Venter MV2 (Sizes 175-400) - Install and Operating Manual User Manual

Page 3: Mighty venter power vent system

Mighty Venter Power Vent System

Page 3

SECTION 1.

1a. General Information

WARNING

The MV1 and MV2 Mighty Venter must be installed

in accordance with the procedures outlined in these

instructions. Warranty applies only if the installation

and operating instructions applicable to the model

purchased are expressly and completely followed.

The Laars Mighty Venter, Models MV1 and

MV2, are designed to make side-wall venting possible

for Laars hot water boilers, Models HH, PH, VW and

PW, sizes 175 - 400. Both the MV1 and MV2 are

equipped with a fan-prover switch which disables the

gas valve if the Power Venter fails to operate.

The Mighty Venter installation must comply with

the latest edition of the National Fuel Gas Code, ANSI

Z223.1, and in Canada, CAN1-B149.1 or .2 and all

local codes that apply. The installation must include

the draft hood assembly shipped with the boiler,

including vent damper if required.

1b. Vent Sizing

Take into consideration the dimensions in Table 1

when designing the vent system. The vent pipe length

shown includes all vent pipe before and after the

Power Venter.

1c. Inspection and Unpacking

Immediately upon receiving the Mighty Venter

kit, inspect the shipment packaging for damage.

Record any damage on the shipping documents.

Unpack the equipment and carefully inspect it for

obvious damage caused in shipment. If any damage is

found, YOU must file a claim with the transporter. The

transporter will not accept a claim from the shipper,

Laars Heating Systems.

The Mighty Venter kit includes three cartons:

Carton 1. Power Venter (MV1 or MV2)

Carton 2. Vent Hood

Carton 3. Vent Reducers/Adapter

Verify the contents of each carton by checking

against the parts list on page 8.

1d. Installer Information

1.

Before beginning the installation, read these

instructions completely and make sure each part

is placed to safely vent flue gases to the

outdoors.

2.

Carefully read the installation instructions

located in the Side Wall Vent Hood carton.

3.

Laars does not provide the vent pipe necessary

for this installation. Use Table 1 as an aid in

selecting the proper vent pipe diameter.

4.

Locate the Power Venter as close as possible to

the point of termination (i.e., the wall). This will

insure the vent pipe between the boiler and the

Power Venter inlet is under negative pressure.

5.

Make sure the power supply is adequate for the

Power Venter motor requirements. Do not add

the Power Venter to a circuit where the total load

is unknown.

Caution

To prevent personal injury and equipment damage,

disconnect the power supply to the hot water boiler

when working on the Power Venter.

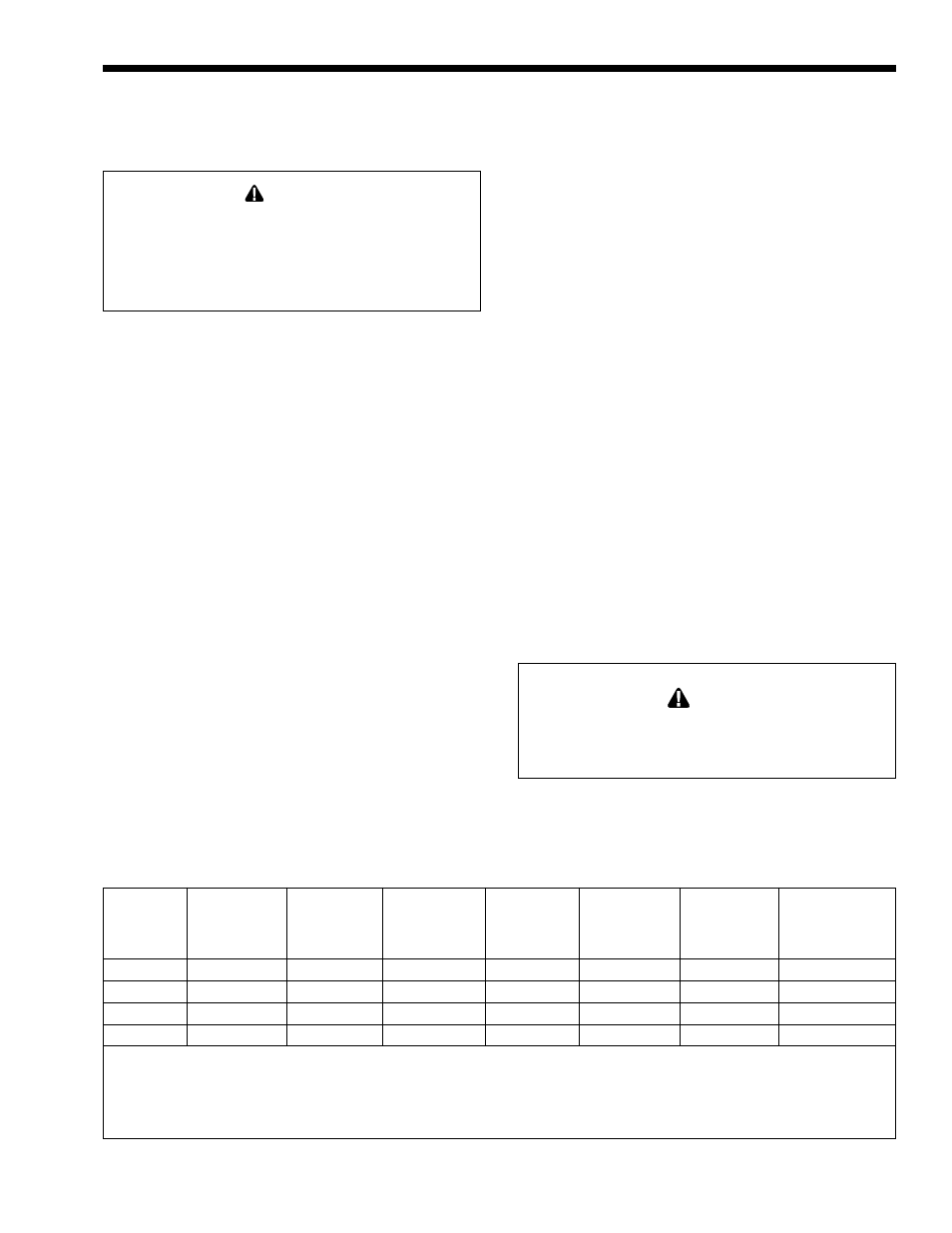

Table 1. Critical Vent Sizing Data.

Notes:

1. Table 1 is for single boiler installations only.

2. To calculate the equivalent vent pipe length, add the length of the straight pipe plus 10 feet (3.0m) for every

90° elbow and 5 feet (1.5m) for every 45° elbow.

3. Vent pipe reducers will be supplied by Laars.

Minimum

Maximum

Mighty

Boiler/

Mighty Venter

Boiler/Heater

Vent Pipe

Equivalent

Equivalent

Mighty Venter

Venter

Heater

Order Number

Outlet Diameter

Diameter

Pipe Length

Pipe Length

Diameter

Model

Size

in

mm

in.

mm

feet

m

feet

m

in

mm

MV1

175

10718702

6

152

4

102

11

3.4

90

27.4

4

102

MV1

250

10718703

7

178

6

152

11

3.4

100

30.5

4

102

MV2

325

10718704

8

203

6

152

11

3.4

100

30.5

6

152

MV2

400

10718705

9

229

6

152

11

3.4

100

30.5

6

152