Tensioning v-belt drives – I.C.E. BMA-136 HBR User Manual

Page 16

15

TENSIONING V-BELT DRIVES

1. Ideal tension is the lowest tension at which the belt will not slip under peak load conditions.

2. Check tension frequently during the first 24-48 hours of operation.

3. Over-tensioning shortens the belt and bearing life.

4. Keep belts free from foreign material that may cause slip.

5. Make V-drive inspection on a periodic basis. Tension when slipping. Never apply belt dressing as this will damage the

belt and cause early failure.

Check and tighten belt tension. The following procedure is recommended for tightening belts:

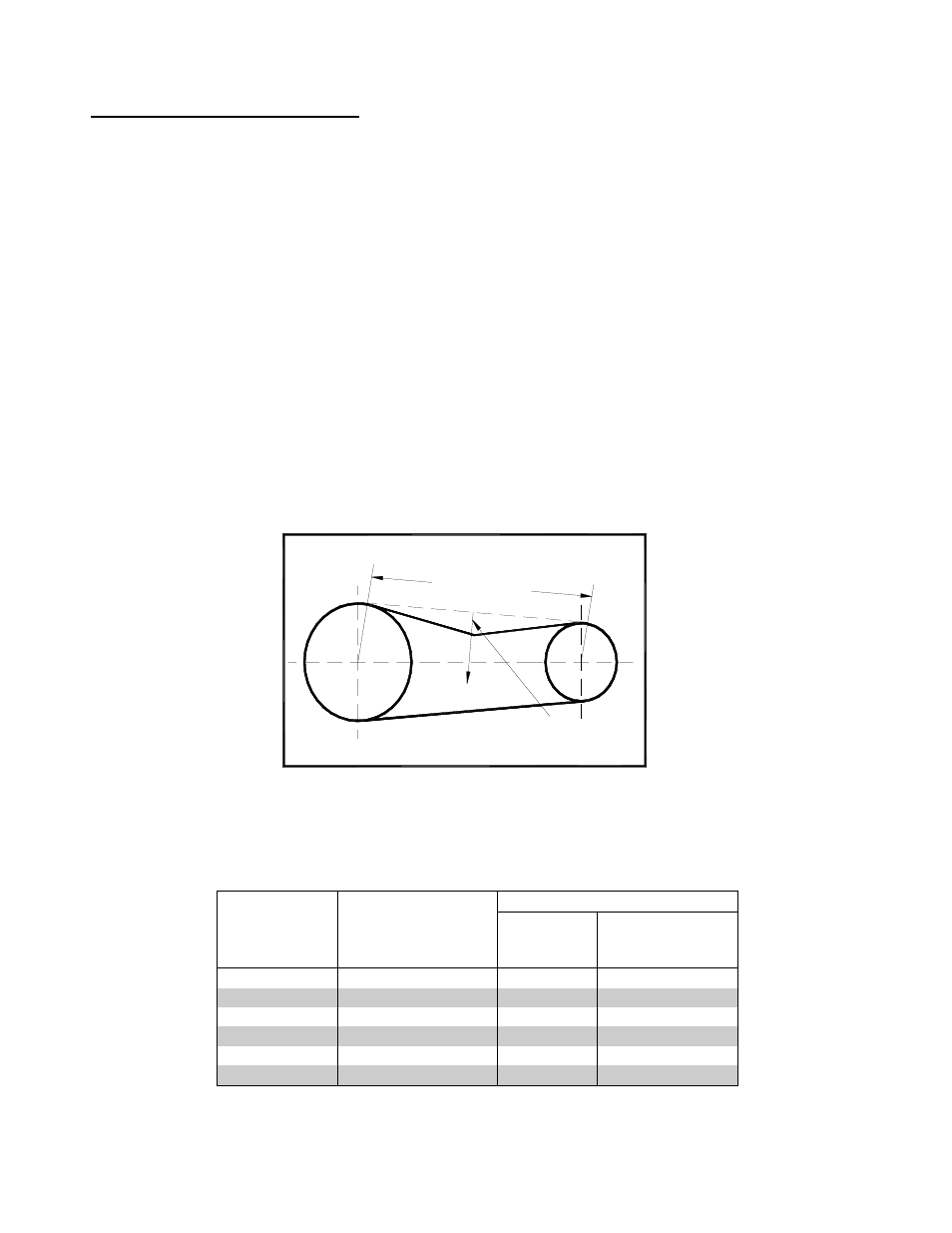

a) Measure span “X” shown in Figure A.

b) At the center of span length “X”, apply a force perpendicular to the span and large enough to deflect belt 1/64” for

each inch of span length. Example- the required deflection for a 40” span would be 40/64” or 5/8”.

c) Compare the force applied with the values given in Table III. If force is between the minimum and maximum range

shown, the drive tension should be satisfactory. A force below the minimum value indicates an under tightened belt

and force that exceeds the maximum value indicates an over tightened belt.

TABLE III

BELT CROSS

MOTOR PULLEY

DEFLECTION FORCE

SECTION

PITCH DIAMETER

MINIMUM

MAXIMUM

(Marked on

Belt)

3.0” - 3.6”

2.62lbs.

3.25lbs.

A

3.8” - 4.8”

3.0lbs.

4.0lbs.

5.0” - 7.0’

3.25lbs.

5.0lbs.

3.4” - 4.2”

3.0lbs.

5.0lbs.

B

4.4” - 5.6’

4.0lbs.

5.87lbs.

5.8” - 8.6”

5.25lbs.

7.87lbs.

FIGURE A

FORCE

SPAN LENGTH X

PER INCH OF SPAN

DEFLECTION 1/64"