Install the servos & make the pushrods – Great Planes SlowPoke 15 Kit - GPMA0491 User Manual

Page 25

❏

20. Carve and sand the turtle deck top to blend with the

rounded shape of the turtle deck formers. Note: The turtle

deck top requires less shaping toward the fin.

❏

21. Using leftover balsa, make fillets around the front of

the stab and lower turtle deck stringer.

Wow! Step back and take a good look. Pat yourself on the

back! You are completely finished framing your SlowPoke!

Nice work.

❏

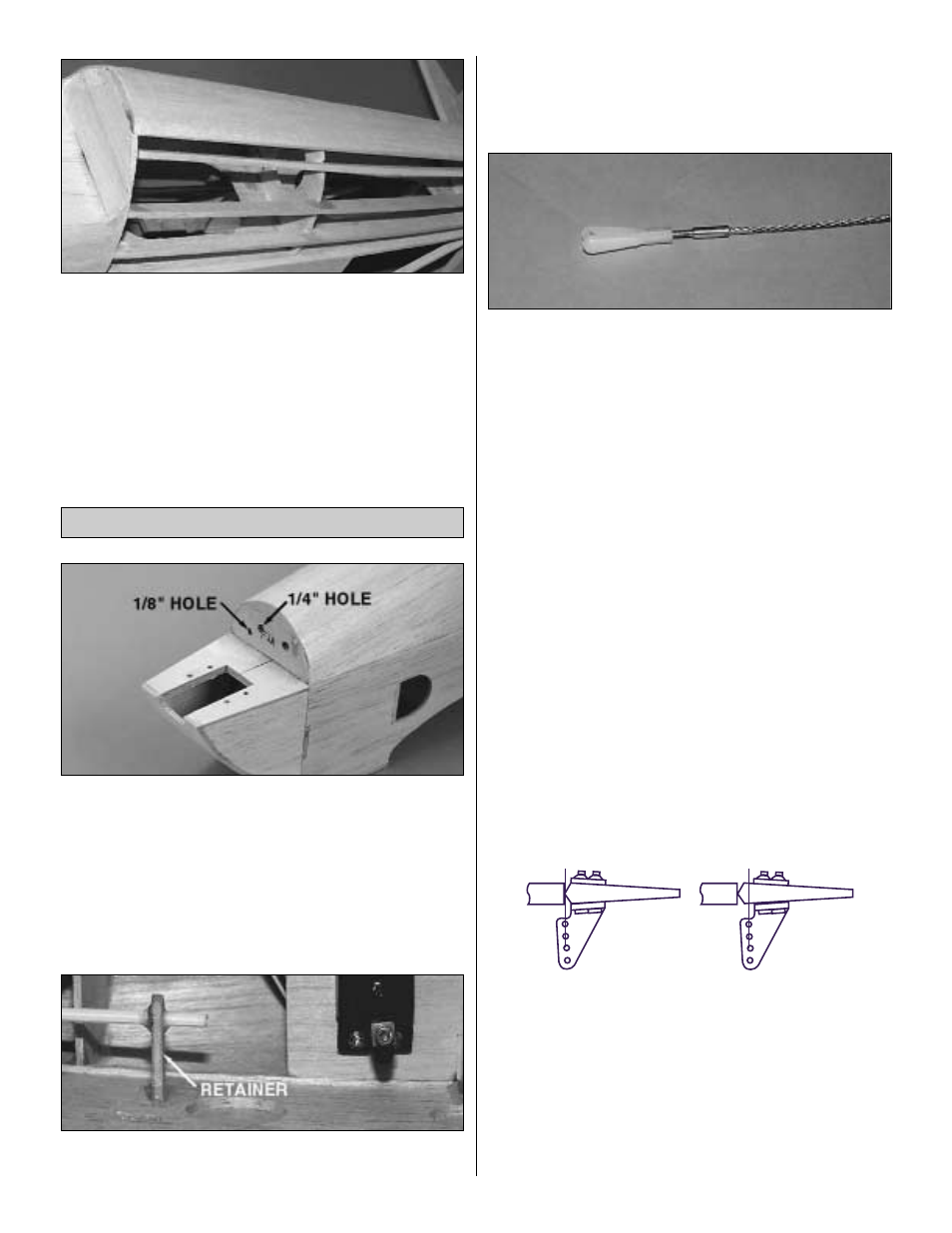

1. Place the engine on the mount. Mark former F1A for

two fuel line holes and one throttle pushrod hole. Remove

the engine and drill the two 1/4" fuel line and one 1/8"

pushrod holes.

❏

2. Select the 24" white flex cable outer guide tube for the

throttle. Slide it through its hole in F1A until it extends

halfway between F2A and F3A. Use medium CA to glue it

into F1A. Cut it flush with the outside of F1A.

❏

3. From leftover 1/8" ply, cut a throttle pushrod retainer.

Glue it in place against the fuse side as shown on the plan.

❏

4. Mount the throttle servo as shown on the plan. Install

a Great Planes Screw-Lock Connector (provided) onto the

second hole of the throttle servo arm.

❏

5. Solder the threaded coupler to the 24" long throttle cable

with silver solder. Screw a nylon clevis onto the coupler.

❏

6. Mount the engine. Slide the throttle cable through the

guide tube you installed in step 2. Attach the clevis to the

throttle arm on the carb.

❏

7. Cut the excess cable off 1" behind the Screw-Lock

Connector on the throttle servo. Insert the throttle cable

through the Screw-Lock Connector.

❏

8. Cut the 35" pushrod wire (threaded on both ends) into

two 17-1/2" long pushrods. Screw a clevis at least 14 turns

onto one rod, making the rudder pushrod. Slide the pushrod

wire through the rudder pushrod guide tube, which is the

guide tube on the left side of the fuselage. Remove the

backing plate from a nylon control horn and connect the

horn to the clevis in the outer hole. Fit the rudder to the fin,

using the hinges to hold them in place. DO NOT GLUE.

❏

9. Position the control horn on the rudder as shown in the

sketch and on the plan. Use a ballpoint pen to mark the

location of the control horn mounting holes and drill 3/32"

holes through the rudder at the marks. Temporarily mount

the control horn to the rudder with the backing plate and

2-56 x 5/8" screws.

Correct

Incorrect

Install the Servos & Make the Pushrods

25