Great Planes Rapture 40 - GPMA0220 User Manual

Page 10

❏

7. Set the fin and rudder aside. Mark the centerlines and

hinge locations and cut the hinge slots on both elevators

and the stab the same way, but don’t cut the “V” until

instructed to do so.

❏

8. With the elevators temporarily connected to the

stabilizer with the hinges, determine which side looks best.

Write “bottom” on the other side of the center of the stab.

❏

9. Place the joiner wire on the bottom of the stab as

shown. Use a ballpoint pen to mark the location of the ends

of the joiner wire where it will go into the elevators.

❏

10. Extend the lines across the bottom of the elevator

using a small square.

❏

11. Drill a 9/64" [3.6mm] (or 1/8" [3.2mm]) hole 1" [25mm]

deep into both the elevators centered on the lines.

❏

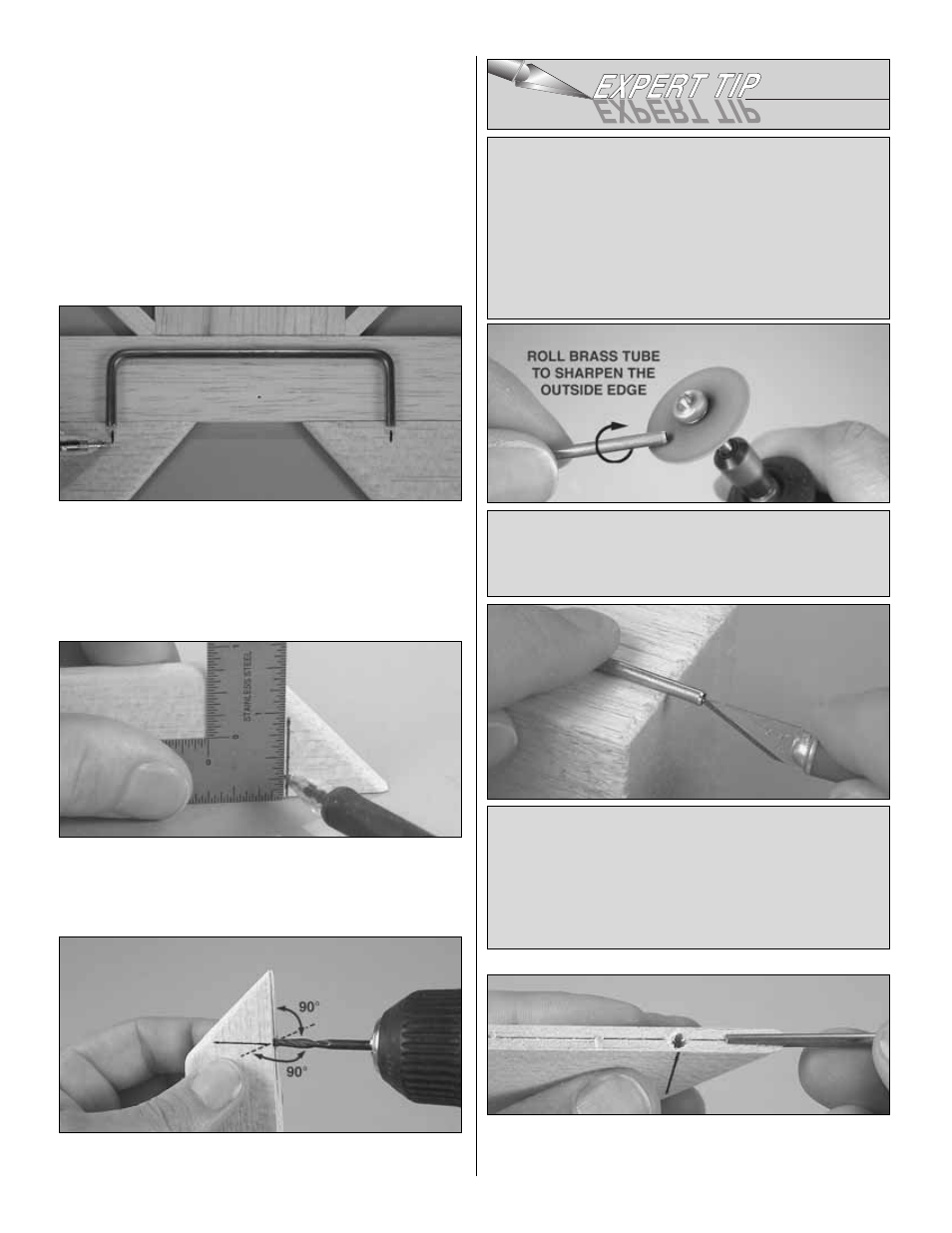

12. Use a 1/8" [3.2mm] brass tube sharpened on the end

or a hobby knife to cut a groove in both elevators to

accommodate the joiner wire.

Use a hobby knife with a #11 blade to sharpen the inside

of the tube by rolling it on a wood block.

The tube can be turned either by hand or by an electric

drill. After the hole has been cut the material will usually

stick inside the tube. The balsa “plug” can be removed

with a wire or the next size smaller tube.

Sharpen the outside of the tube using a fiber reinforced

cut-off wheel or a metal file. If using a cut-off wheel, be

certain to use the reinforced variety and always wear

safety glasses.

HOW TO SHARPEN A BRASS TUBE FOR

CUTTING BALSA

Often, using a brass tube sharpened on the end to cut

holes (or grooves) in balsa provides a much cleaner,

more accurate hole than would a regular drill bit. The

sharpening procedure below works on any size of hobby

tubing (available from K&S at hobby shops, craft stores

and hardware stores).

10