Great Planes PT-17 Stearman .91-1.20 ARF - GPMA1349 User Manual

Page 24

❏

3. On the right side of the fuselage, slide one wire into

the opening closest to the back of the fuselage. Install a

nylon control horn onto the clevis. Position the control horn

on the rudder, positioning it the same way you did with the

ailerons. Mark the location for the screw holes. Drill through

the marks you made with a 1/16" [1.6mm] drill bit, drilling

only into the plywood plate. Do not drill through the

rudder! Install and then remove two 2-56 x 5/8" [16mm]

machine screws. Apply a couple drops of thin CA into the

holes. Once the glue has cured, mount the horn and the

nylon mounting plate to the rudder with the screws.

❏

4. Install the two elevator pushrods using the same

procedure used for the rudder. Be sure when installing the

control horn on the right elevator that you install it so it

does not conflict with the rudder control horn.

❏

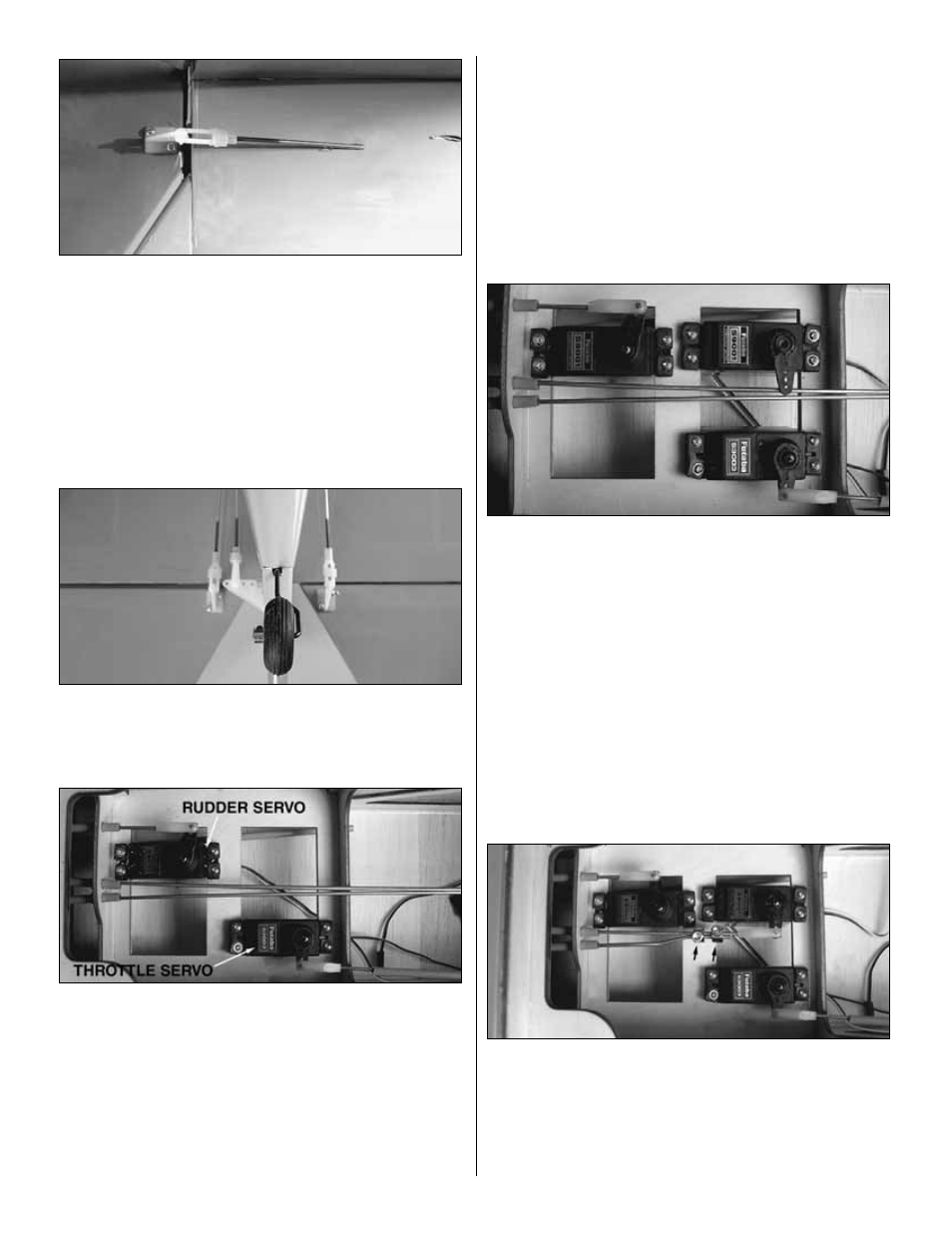

5. Place your rudder servo into the servo tray as shown,

positioning the last hole of the servo arm over the pushrod

wire. Drill a 1/16" [1.6mm] hole through each of the mounting

holes. Remove the servo, then install and remove a servo

mounting screw into each hole. Apply a couple drops of thin

CA into the holes to harden the threads. When the glue has

cured, permanently mount the servo to the servo tray.

❏

6. Center the rudder and the rudder servo, then install

the servo arm. At the point the pushrod wire intersects the

last hole in the servo arm make a mark. Bend the wire 90

degrees on that mark. Install a nylon FasLink and cut off the

excess wire the same as was done with the throttle servo.

❏

7. Place your elevator servo into the servo tray as

shown, positioning the last hole of the servo arm over the

inside pushrod wire. Drill a 1/16" [1.6mm] hole through each

of the mounting holes. Remove the servo, then install and

remove a servo mounting screw into each hole. Apply a

couple drops of thin CA into the holes to harden the threads.

When the glue has cured permanently, mount the servo to

the servo tray.

❏

8. Bend the outer elevator pushrod as shown. Cut off

the excess wire. Center both of the elevators, then center

the elevator servo. Secure the two pushrod wires with two

5/32" [4mm] wheel collars and 6-32 x 1/4" [6.4mm] socket

head cap screw. Attach the elevator pushrod to the servo

arm with a nylon FasLink using the same technique used on

the rudder and throttle.

24