Great Planes PT-60 Kit - GPMA0119 User Manual

Page 30

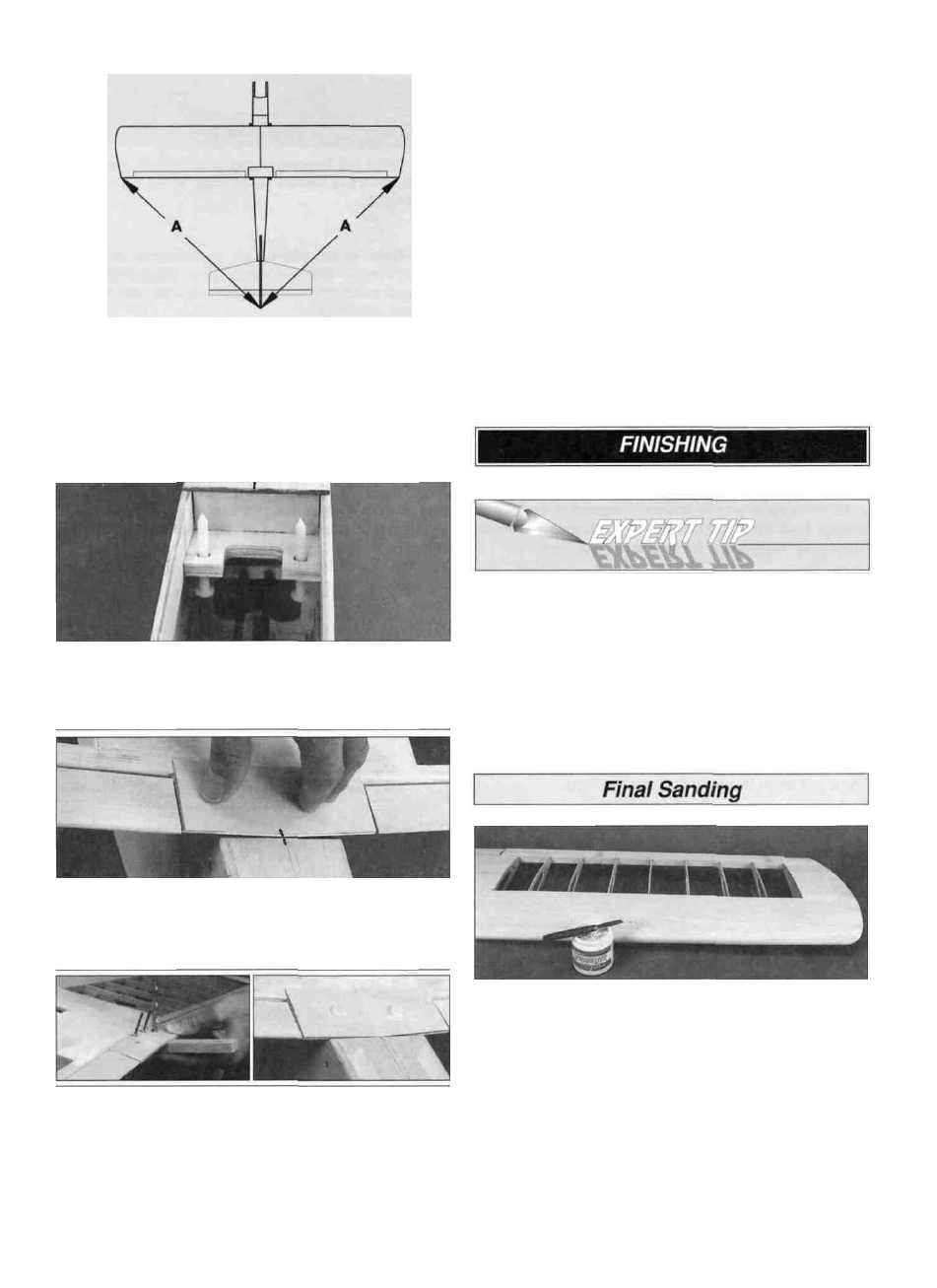

ALIGN THE WING

while holding the drill so the bit is perpendicular to the

top surface of the wing. Use a hardwood "backup" to

prevent the ply TE plate from splintering.

CAUTION: Keep your fingers out of the way and stop

drilling as soon as you feel the drill cut through the TE

plate. Enlarge the holes with a round file if needed, then

test fit the wing using the bolts.

Well, you are through the framing stage and you've given

life to a box of balsa. Looks pretty neat, eh? Time to clean

up your workbench once again, have a soda, and forge

ahead to the "finishing" stage.

A=A

(FROM WINGTIP TO FIN)

D 17. Align the wing by using a string or tape measure

to equalize the distance from each wing tip to the TE of

the fin. Once aligned, lightly draw matching reference

marks on the ply TE plate and the fuse top (See photo at

step 19.) Remove the wing.

D 18. Sharpen the tips of both nylon wing bolts to a

point as shown. Screw the bolts through the blind nuts

from underneath the wing bolt plate. The points should

be 1/8" above the height of the wing saddle.

REPAIRING SURFACE "DINGS"

Many surface blemishes on a framed model are caused

by bumps and balsa chips on the work surface. This type

of ding is best repaired by applying a drop or two of

window cleaner or tap water to the blemish, then running

a hot sealing iron over the spot to expand the wood

fibers. After the surface has dried, sand the expanded

area smooth.

D 19. Plug the wing dowel into F-2 and gently lower the

TE. After the wing is aligned with your reference marks,

press down on the TE to mark the bolt hole locations by

"dimpling" the TE with the sharpened wing bolts.

D 20. Remove the wing, then drill 1/4" (or 17/64" if you

have that size bit) holes through the TE at both marks,

D 1. Fill any scuffs, dings and the forward end of the

pushrod tube exit slots with balsa filler (Hobbico HobbyLite

HCAR3401 recommended). After the filler has hardened,

cut and sand the pushrod tubes flush with the fuse sides,

then sand the entire structure with progressively finer

grades of sandpaper, ending with 320-grit. When you think

the job looks good, sand some more to make it better. You'll

be glad you did.

30