Brushless motor installation – Great Planes Matt Chapman Eagle 580 46/EP ARF - GPMA1281 User Manual

Page 17

17

❏

14. Insert the pushrod through the outer pushrod tube

and through the screw-lock pushrod connector on the throttle

servo arm. Connect the clevis to the throttle arm on the

carburetor. Make any necessary bends in the pushrod so the

pushrod can actuate the throttle without contacting the motor

mounting box. When satisfi ed, adjust the pushrod position in

the screw-lock pushrod connector so that the throttle servo

properly opens and closes the carburetor. Use the radio

system to test the operation of the throttle. Tighten the SHCS

in the screw-lock pushrod connector and cut off the excess

pushrod 1/4" [6mm] behind it. Glue the outer pushrod tube

support to the second former and glue the outer pushrod

tube to the outer pushrod tube support.

❏

15. CA glue the plywood fi ll line clip to the bottom center

of the fi rewall. The clip can be fuelproofed with epoxy. Cut

the fuel tubing coming from the tank to the proper length and

connect the carb line to the engine. The fi ll line (if installed)

should be plugged with the included aluminum fuel line

plug and will conveniently fi t into the fi ll line clip. Be sure to

replace the fuel line plug after fi lling or draining the fuel tank.

The pressure line will be installed onto the muffl er after the

cowl installation section.

❏

16. Seal up the electric cooling hole cutout with thick CA

or epoxy.

Brushless Motor Installation

The Eagle 580 Matt Chapman .46-.81/EP ARF is designed

to be fl own with a .46 to .61 two-stroke glow engine, .52 to

.81 four-stroke glow engine, or a brushless out-runner motor.

If you have installed a glow engine, skip this section as it only

contains information relevant to installing a brushless motor.

Be sure to read and understand the instructions that come

with the ESC and motor before attempting to operate the

system. Also read the lithium battery handling and usage

warning on page 26 of this manual.

❏

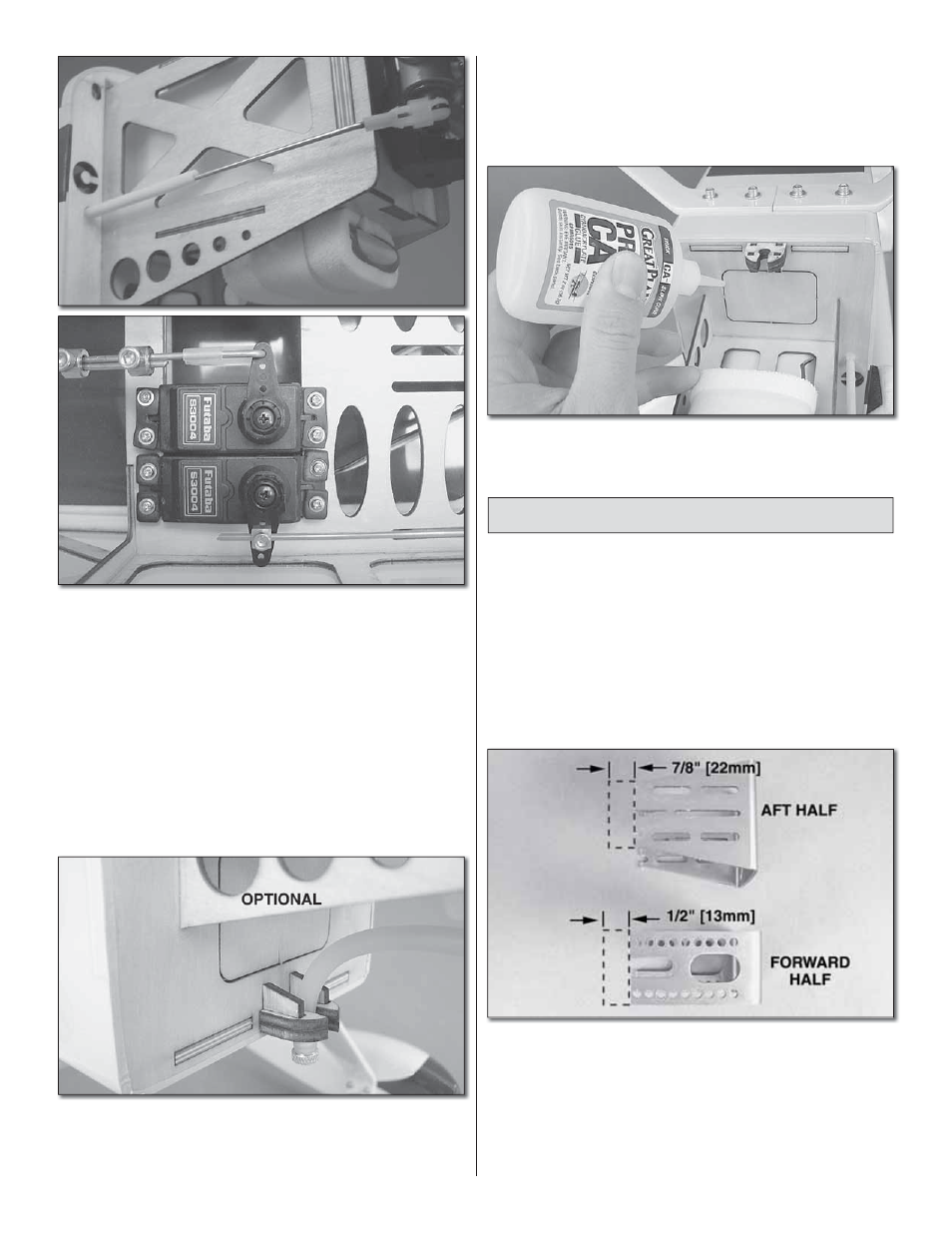

1. In order to achieve the required distance from the

fi rewall to the face of the bolt-on prop adapter, the ends of

the motor mount halves must be cut shorter. A hacksaw

or rotary tool with a cutoff wheel work well for this. The aft

motor mount half must be shortened by 7/8" [22mm] and

the forward motor mount half must be shortened by 1/2"

[13mm]. Reassemble the motor mount using threadlocking

compound on the mount screws.