Great Planes ElectroStik EP RxR - GPMA7500 User Manual

Page 7

7

PREPARATIONS

Use a covering iron with a covering sock on medium/high heat

to tighten any loose covering if necessary. Apply pressure over

sheeted areas to thoroughly bond the covering to the wood.

ASSEMBLY

Assemble the Wing

❏

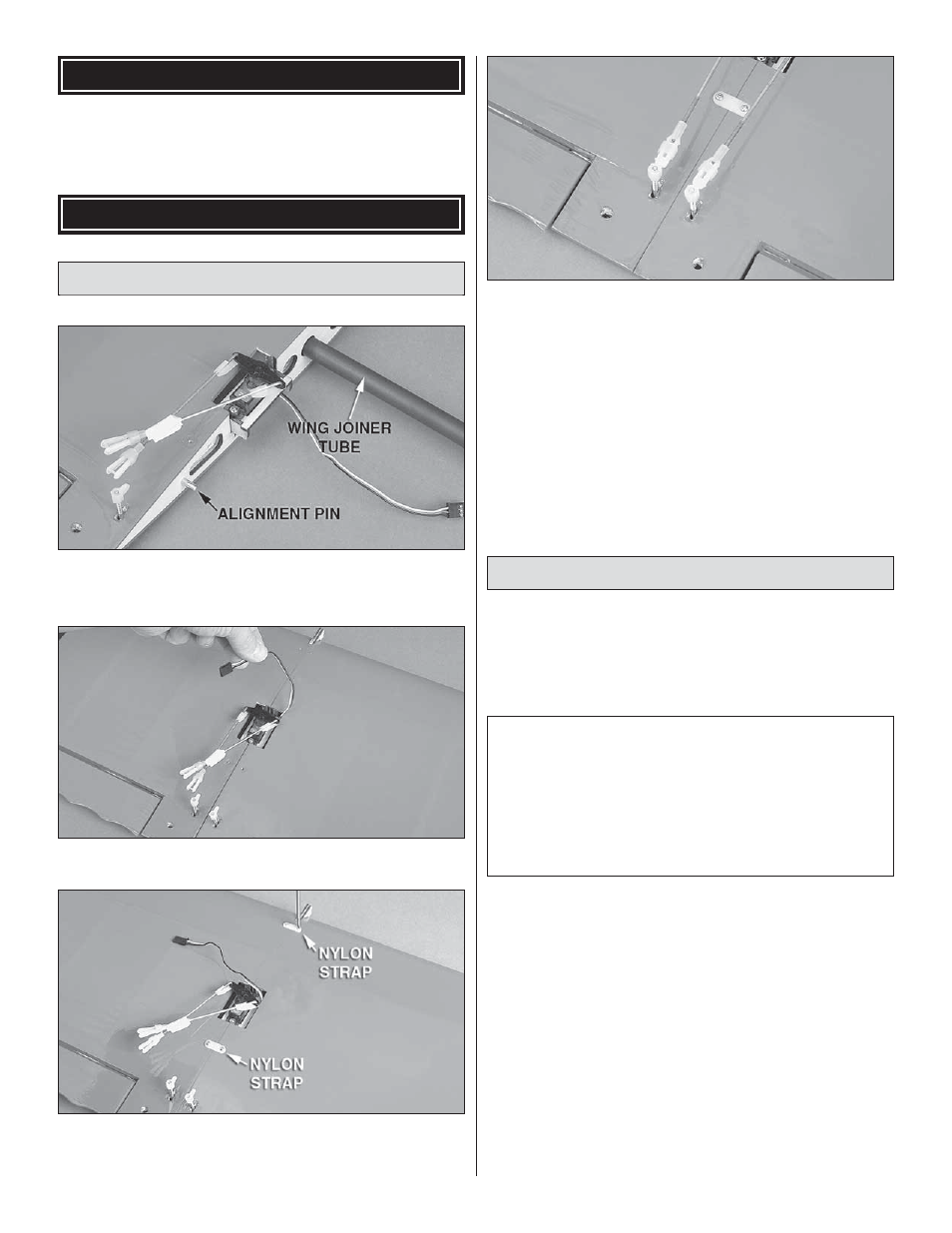

1. Install the 20-7/8" [530mm] carbon fi ber wing joiner

tube and the 1" [25.4mm] steel alignment pin into the right

wing panel as shown.

❏

2. Carefully slide the left wing panel in place as shown,

making sure that the servo lead does not get pinched.

❏

3. Fasten the wing halves together using the two included

nylon straps and four #2 x 3/8" [9.5mm] self-tapping screws

as shown.

❏

4. Use your radio system to center the servo. Position the

ailerons in the neutral position with tape or small clamps

and connect the clevises to the aileron torque rod horns.

Make any necessary adjustments by threading the clevises

up or down the pushrod. When satisfi ed, slide the silicone

clevis retainers to the ends of the clevises.

Wing assembly is complete.

Optional - Dual Aileron Servos

The Great Planes ElectroStik EP RXR comes equipped with

dual aileron servo trays for dual aileron servos. To install

the dual aileron servos, follow these instructions:

For this section you will need:

1

Additional Servo (same

type as your existing

aileron servo.)

1 “Y”

harness

2 6" [152mm] Pushrods

2 Nylon

Clevises

2 Silicone Clevis Retainers

2 FasLinks

1 Servo

Mounting

Hardware

Set

1 Screwdriver

1 Wire

Cutter

1 Pliers

1 Thin

CA

1 Trim Sealing Iron

❏

1. Disconnect the aileron servo pushrods from the aileron

horns and remove the original aileron servo.

❏

2. Remove the two nylon straps and separate the

wing panels.

❏

3. Locate the dual aileron servo tray in each wing panel.

They are located on the underside of the wing at the 4th bay

in from the wing tip. Trim the covering over the opening and

use a sealing iron to seal the covering to the tray.

❏

4. Use a 1.5mm [1/16"] drill bit and drill mounting holes for

the servos. Insert and then remove a servo mounting screw

into each hole and put a drop of thin CA into each hole to

harden the threads.

7