Great Planes Big Stik 60 ARF MonoKote - GPMA1221 User Manual

Page 14

❏

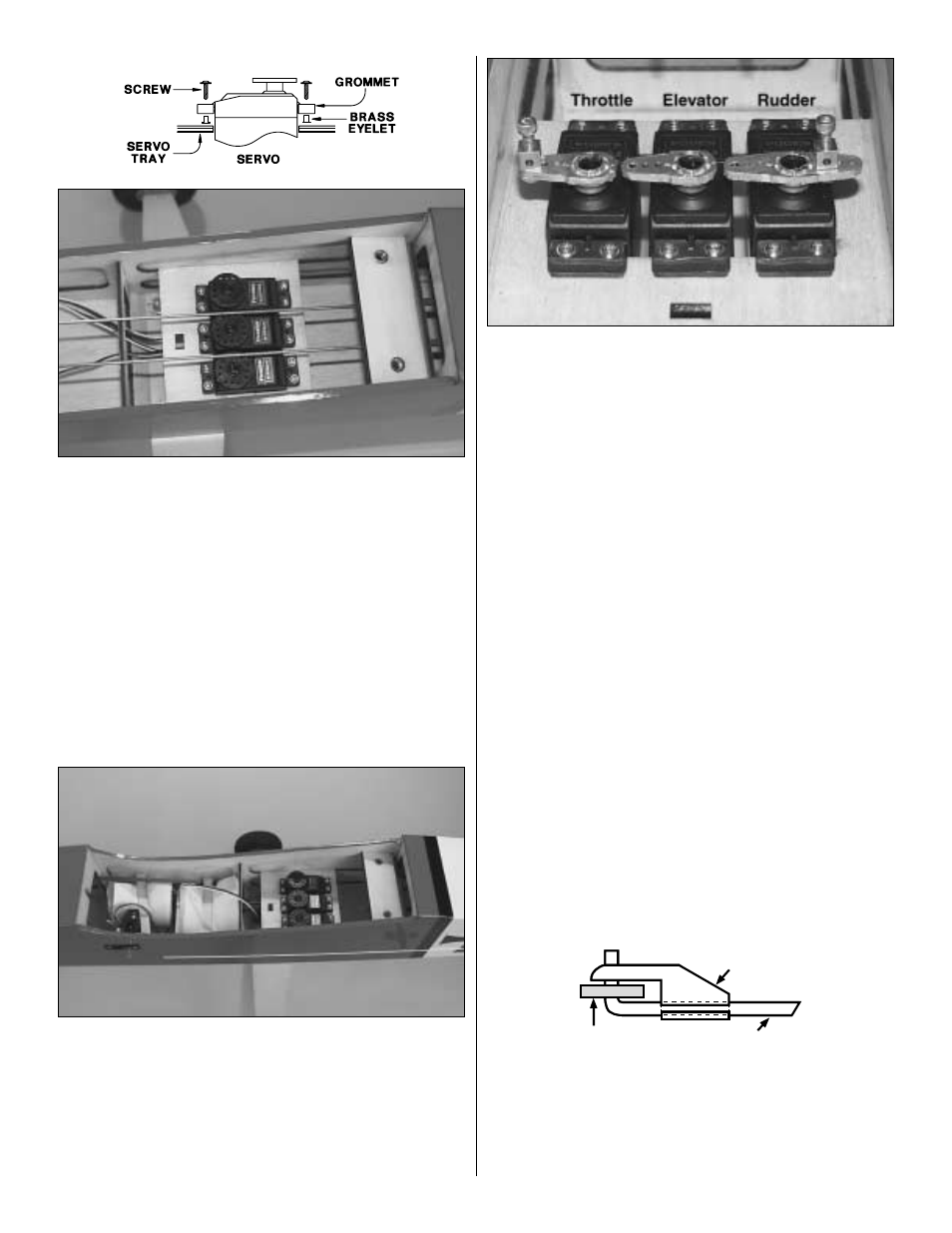

3. Use the following sequence for mounting the servos

into the servo tray:

❏

A. Install rubber grommets and brass eyelets in

the servos.

❏

B. Test fit the servos in the tray.

❏

C. Mark servo hole locations on the tray, then drill

1/16" [1.5mm] pilot holes through each mark. Harden

the holes with a drop of thin CA through each hole.

❏

D. Referencing the photo above for orientation,

mount the servos with the screws provided with your

radio system.

❏

4. Following the manufacturer's recommendations, hook

up the three servos, the receiver, switch and battery as

shown in the photograph. Wrap the receiver and battery in

1/4" foam, then hold them in place by gluing small balsa

sticks (not included) above them. We added a Great Planes

Switch Mount and Charge Jack (GPMM1000, not included)

for convenience and ease of use at the field, installed on the

left side of the fuselage, away from the exhaust.

❏

5. Turn on your transmitter and receiver and position the

aileron, rudder, elevator and throttle trims and throttle stick

on your transmitter to the center. (This is called “centering”

the servos and will allow you to place the servo horns on the

servos in a neutral position.) Note: The servo arms have

been painted to make them show up better in the photos.

Prepare the servo arms as shown in the photo. You will need

to cut excess arms off the servo horns supplied with your

radio system. This is perfectly normal, as the multi-arm

servo horns are provided for just such purposes. Note that

the rudder servo uses a 2-armed horn.

❏

6. Connect the brass screw lock pushrod connectors with

the nylon retainers to the throttle and nose-gear arm of the

servo horns as shown. Note: The size and shape of servo

horns varies from manufacturer to manufacturer. The

sketches and photos show a typical radio installation with

standard horns. All standard servos should fit the Big Stik

with only minor modifications.

❏

7. Mark the elevator pushrod where it crosses the servo

arm. Enlarge the servo horn holes with a 5/64" [2mm] drill bit.

FasLink

2-56 (.074") Pushrod Wire

Servo Horn

14