FloAire High Velocity Restaurant Duty Utility Set User Manual

Page 3

3

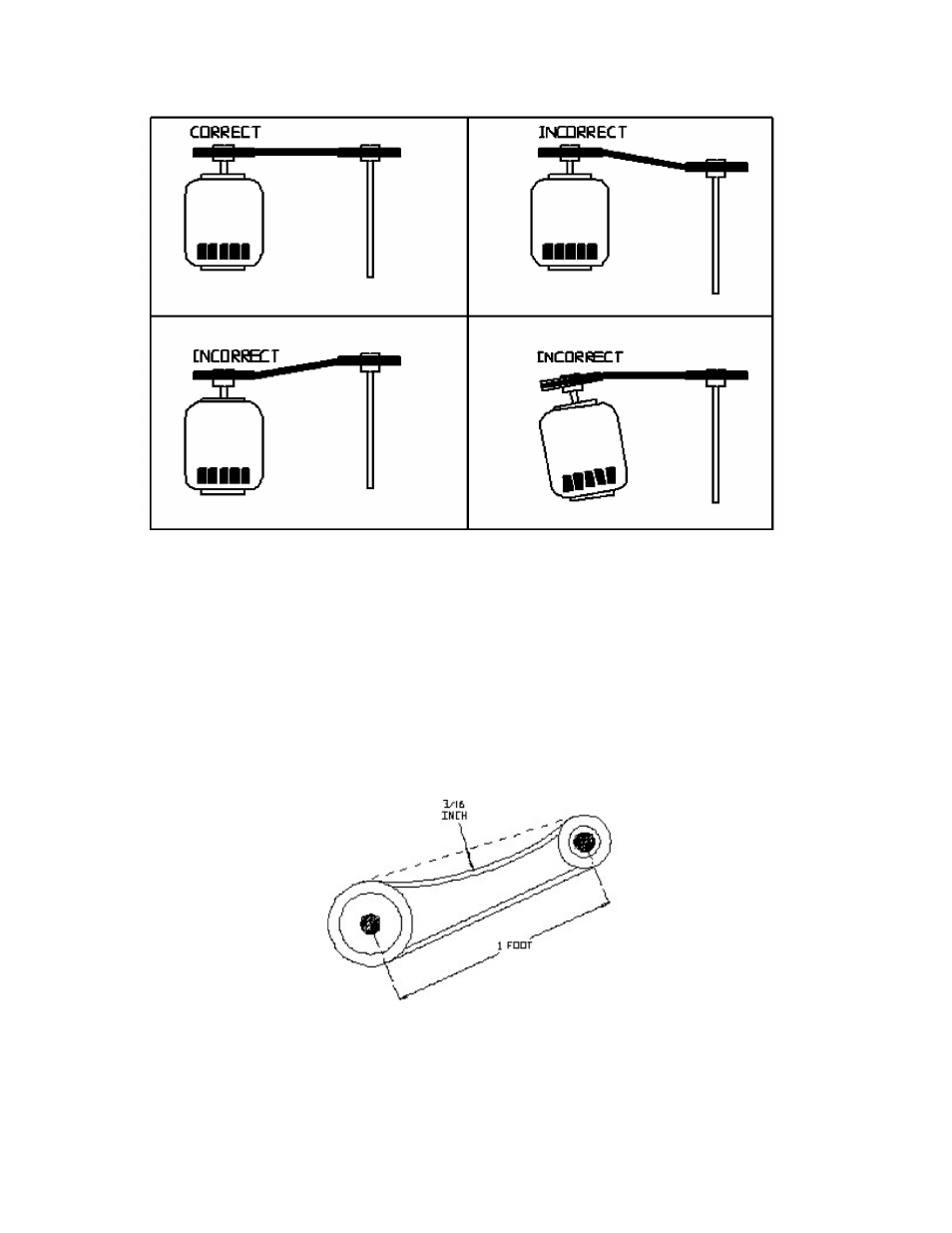

PULLEY ALIGNMENT

Pulley alignment is adjusted by loosening the motor pulley or driven pulley set screws and moving the

pulley on the shaft. See Fig. 2. A straight edge should be used when aligning pulleys.

Fig. 2

BELT TENSION

Belt tension should be checked after the first 48 hours of fan operation. Do not tension belts by changing

the setting of the motor pulley, this will change the fan speed and may damage the motor.

To re-tension belts, with the power to the fan motor OFF. Loosen the fasteners that hold the motor to the

motor mounting plate. Slide the motor to the left or right to adjust the belt tension. Belt tension should be

adjusted to allow 1/64” of deflection per inch of belt span. See Fig. 3. Exercise extreme care when

adjusting V-belts as not to misalign pulleys. Any misalignment will cause a sharp reduction in belt life and

produce squeaky noises. Overtightening will cause excessive belt and bearing wear as well as noise. Too

little tension will cause slippage at startup and uneven wear. Whenever belts are removed or installed,

never force belts over pulleys without loosening motor first to relieve belt tension.

Fig. 3