Equipment development co., inc, Important – EDCO BB14E User Manual

Page 13

Page 13

E-BB14E&BB14G-I-0714

E-SPTS-I-0809

800-638-3326 • edcoinc.com • [email protected]

EQUIPMENT DEVELOPMENT CO., INC.

Belt Adjustment and Replacement:

•

Periodically check belt(s) for damage, same type and are at the proper tension. Do not mix belts. Slipping belt(s) will

overheat causing the cutting speed to be limited and shorten the life of the belts. Over-tensioned belts will shorten the

life of the belt(s) and bearings.

•

On new equipment and after installing new belt(s) of the same type, be certain to re-tension the belt(s) after the

fi rst 4 hours of use. New belts are stiff and require a break in period. Belts that are loose could slip and/or over-

heat.

•

Damaged, stretched or excessively worn belt(s) should be replaced with a new complete set of belt(s) of the same

type. Do not mix belts.

•

Belt(s) must be replaced with the same type.

•

Blade must be realigned every time the belt(s) are tensioned, gas model

only.

Important!

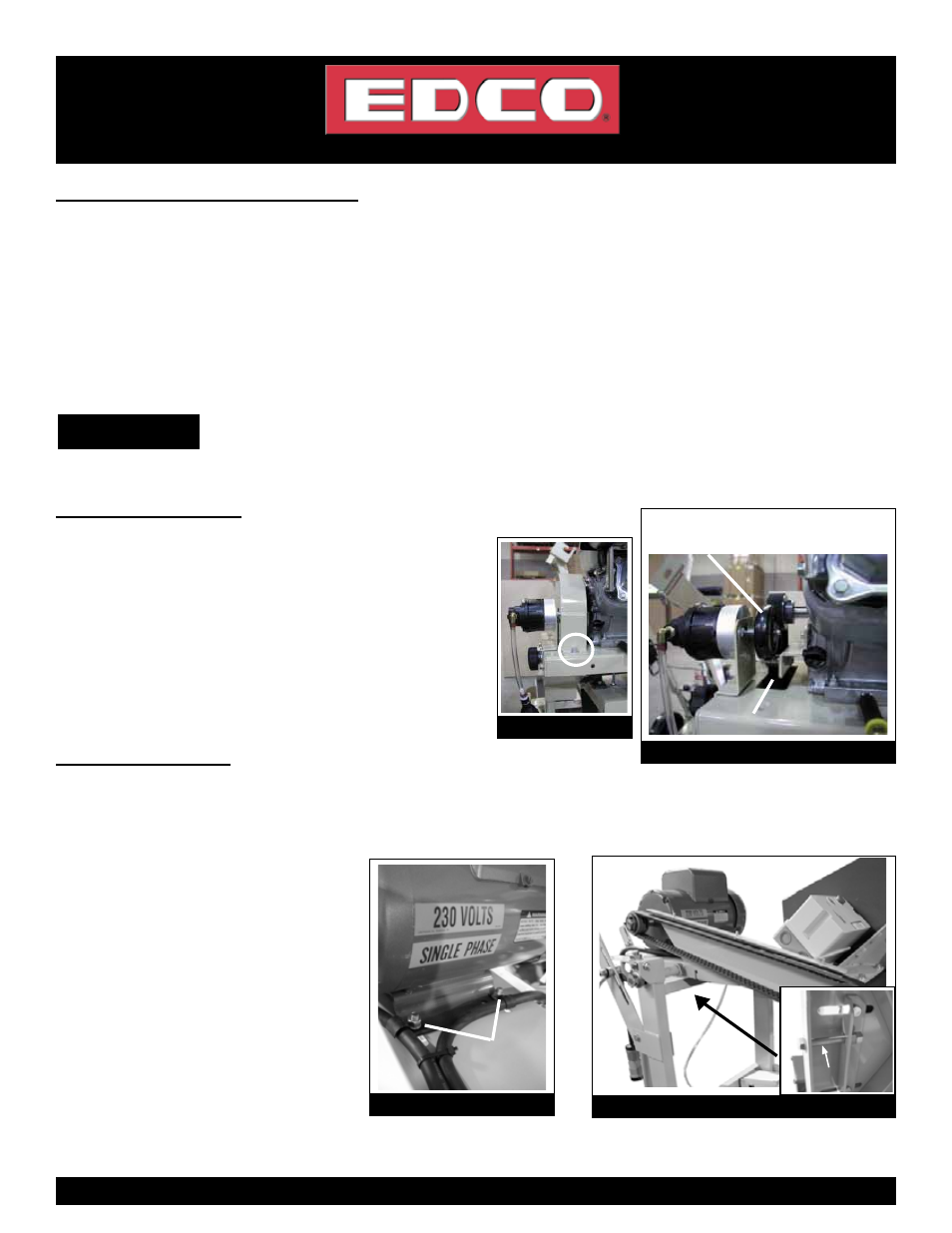

On Electric Models:

NOTE: Due to machine improvements

pictures may not show your particular

machine. The instructions however are the

same.

•

Loosen motor mounts (4)

(Figure 21)

•

Loosen jacking bolt until belts

slide off sheave. (Figure 22)

•

Replace with a new complete

set of belts of same type. Do

not mix belt types.

•

Adjust jacking bolt to tension belts.

•

Square motor to frame.

•

Retighten motor mount bolts.

On Gasoline Models:

•

Access belt from back of machine.

•

Remove two (2) cap screws from both sides of the

belt guard as circled in photo to right (Figure 19)

Figure 19).

Lift off belt cover, Water pump drive wheel and belt

are now accessible.

•

To change drive belt, loosen engine mount bolts

and belt tensioner, tilt engine torward water pump

until belt can be removed.

Figure 19

Water

Pump

Wheel

Drive Belt

Drive Belt

Figure 20

Motor

Mount

Bolts

Figure 21

Jacking

Bolt

Figure 22