Dynaflite GPMA1052 Bird of Time User Manual

Page 9

❏

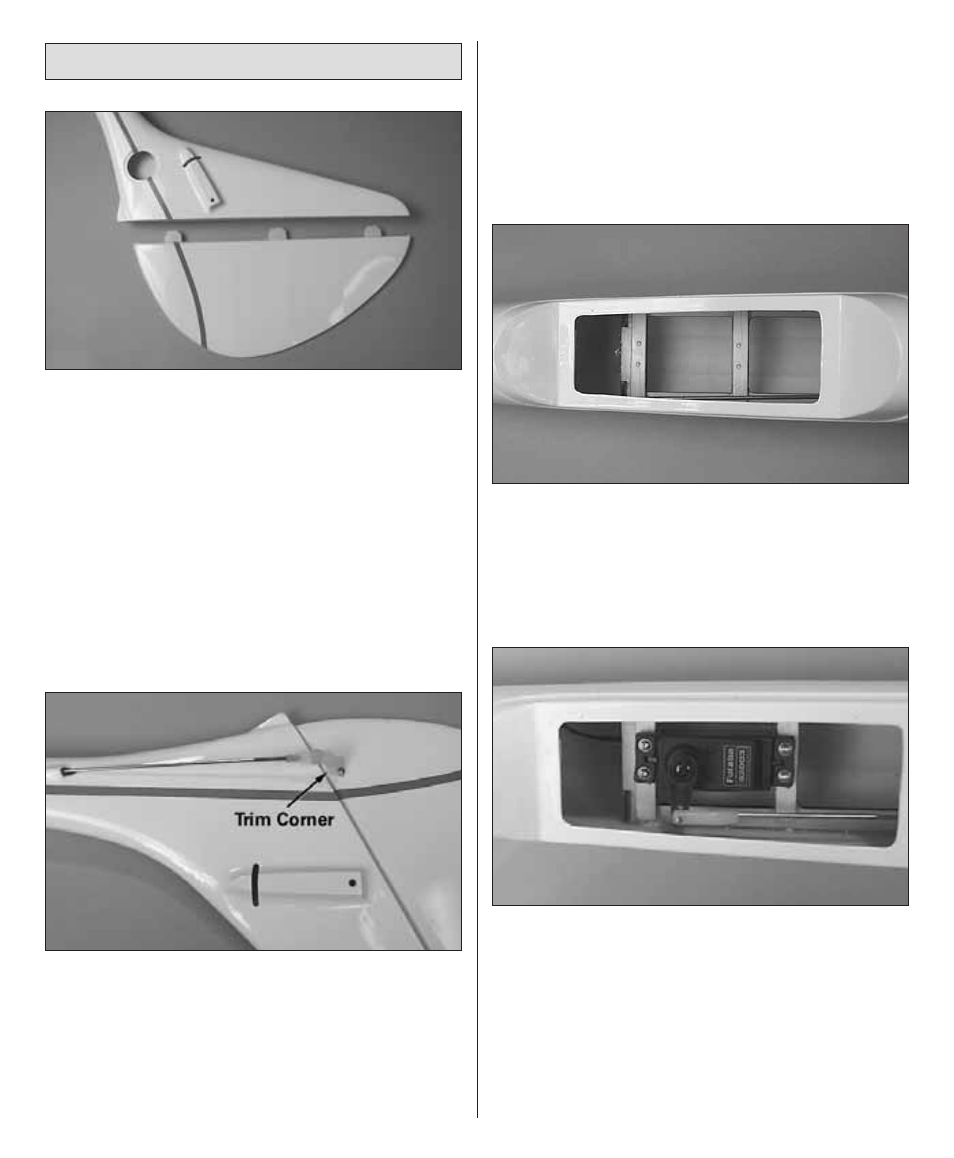

1. Cut three hinges from the supplied CA hinge

material to a size of 3/4" x 1" [19 x 25.4mm]. Snip

the corners off to make the hinges easier to

insert into their slots. Fit the CA hinges in the

precut slots in the rudder and vertical fin. If the

slots are tight, use a hobby knife to widen the

slots. Insert the knife in the slot and rock it back

and forth. It is the rear of the knife blade that

does most of the work. When satisfied with the

fit, glue the hinges in place with six drops of thin

CA on each side of the hinges. DO NOT use any

accelerator. Be sure to leave enough of a gap so

the rudder can reach full deflection.

❏

2. Thread a nylon clevis on the 36" [915mm]

wire pushrod at least 13 full turns. Install a

silicone retainer on the clevis. Insert the pushrod

into the tube in the fuselage. Install a control

horn on the clevis using the hole furthest out on

the horn. Mark the location of the mounting

screw holes on the rudder. Drill 3/32" [2.4mm]

holes for the screws and mount the control horn

to the rudder with the 2-56 x 5/8" [15.9mm]

machine screws and the nylon back plate. Note

that the holes in the front of the control horn (for

the clevis) are in line with the hinge line. Trim the

corner of the control horn and the nylon

backplate as shown in the picture above.

❏

3. Mark the location of the mounting holes for

the rudder servo on the servo tray in the nose of

the fuselage. Drill pilot holes and install the

screws that came with your servo. Remove the

screws and harden the holes with some thin CA.

❏

4. Mount the rudder servo with the grommets,

eyelets and screws supplied with your servo.

Place a servo arm on the servo perpendicular to

the servo. With the rudder centered, mark the

rudder pushrod where it crosses the outer hole in

the arm. Bend the wire up 90 degrees at the mark.

Secure the wire to the servo arm with a nylon

Faslink connector and cut off the excess wire.

Install the retaining screw for the servo arm.

Install the Rudder

9