Audio connections, Security plate & label, Tamper-proof bracket – Drawmer SL22 Sound Level Limiter User Manual

Page 6

6

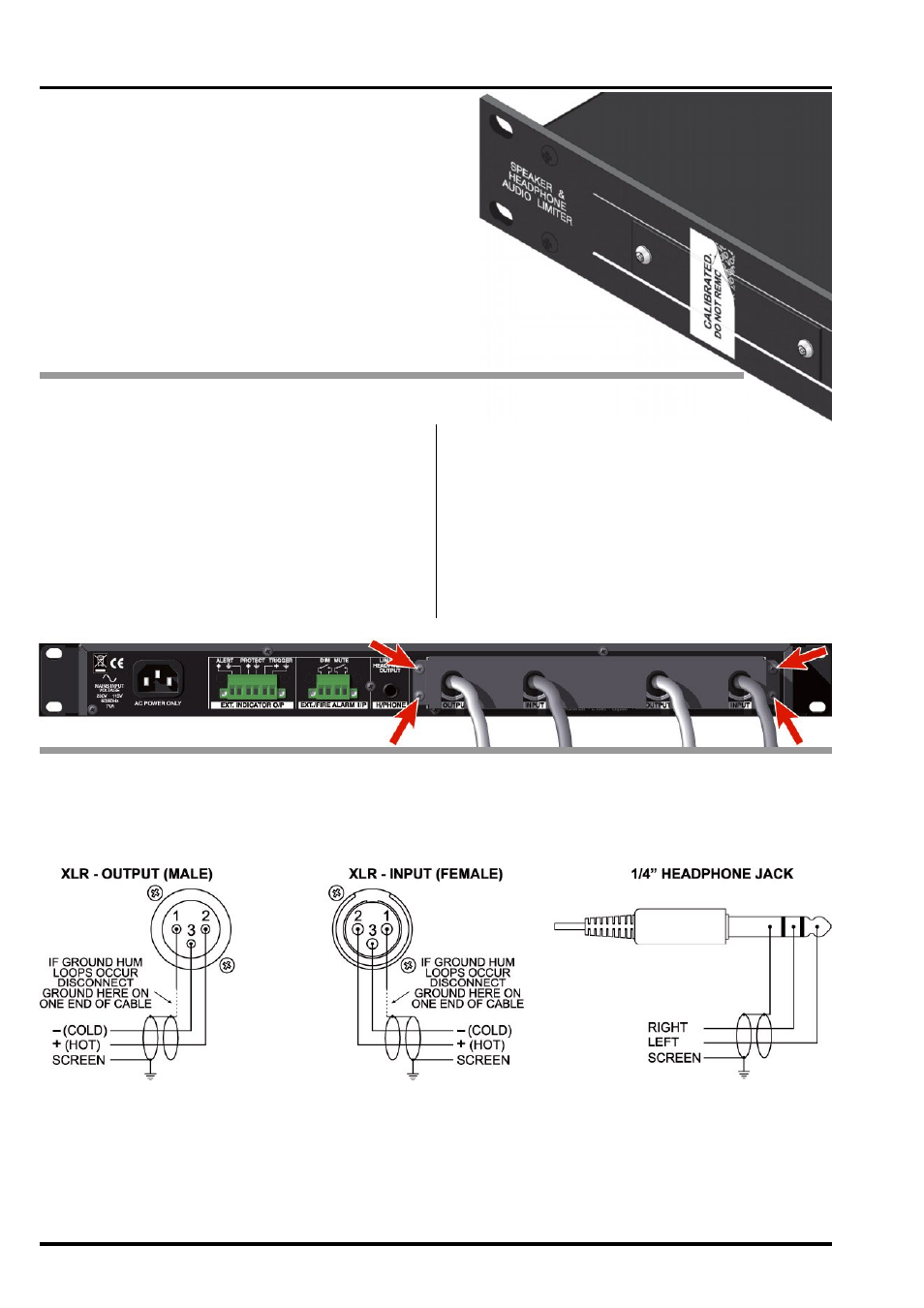

AUDIO CONNECTIONS

The inputs and outputs are electronically balanced on conventionally wired XLRs (pin 1 screen, pin 2 hot, pin 3 cold

and XLR shell is connected to chassis). Balanced use is recommended.

• Interference:

If the unit is to be used where it maybe exposed to

high levels of disturbance such as found close to a

TV or radio transmitter, we advise that the unit is

operated in a balanced configuration. The screens of

the signal cables should be connected to the chassis

connection on the XLR connector as opposed to

connecting to pin1. The 4X4 conforms to the EMC

standards.

• Ground Loops:

If ground loop problems are encountered, nev er

disconnect t he mains earth, but inst ead, try

disconnecting the signal screen on one end of each

of the cables connecting the outputs of the 4X4 to the

patchbay. If such measures are necessary, balanced

operation is recommended.

The front panel has a plate on the front under-which the

two calibration controls sit. This is secured using M3

TORX tamperproof screws. A screwdriver is supplied to

remove this plate, as well as a tamper-proof label that

further secures the SL22’s settings. Once the front panel

security plate has been replaced, after the calibration

process has finished, the label can be placed across so

that it adheres to both the plate and the front panel. If

the security plate is tampered with and the label touched

it will leave a ‘void’ identification, showing that the settings

have potentially been altered and that calibration must

be performed again.

SECURITY PLATE & LABEL

Drawmer have gone to great lengths to make the SL22

tamper-proof by incorporating the locking plate with

tamper-proof screws on the front. However, if the rear of

the unit, along with the power amplifier, were reconnected

then the protection system would effectively be bypassed.

For this reason Drawmer have designed the Tamper-

proof Bracket - trapping the XLR’s in place and making

it extremely difficult to disconnect them without removing

the bracket. This bracket could be specified in order to

conform to Local Authority noise abatement regulations.

Installation of the Tamper-proof bracket could not be

simpler: After setting up the SL22 as described in this

manual, with the XLR’s in place, simply slide the Tamper-

proof Bracket over the rear of the unit, making sure that

the XLR cables locate through the gaps on the bracket.

Next, screw in to place at the four locating points (arrowed

below) using the M3 screws provided. Further protection

can be gained by fitting M3 TORX tamperproof screws,

to a maximum length of 6mm, the same as used on the

front, and utilizing the same tamperproof screwdriver.

In addition, for extra protection, both the SL22 and the

power amp should be locked in a rack, where access to

the rear is very difficult.

TAMPER-PROOF BRACKET