V .checking and trouble shooting, 12 checking reference – COMEUP Chain Hoist (Ver:02) User Manual

Page 14

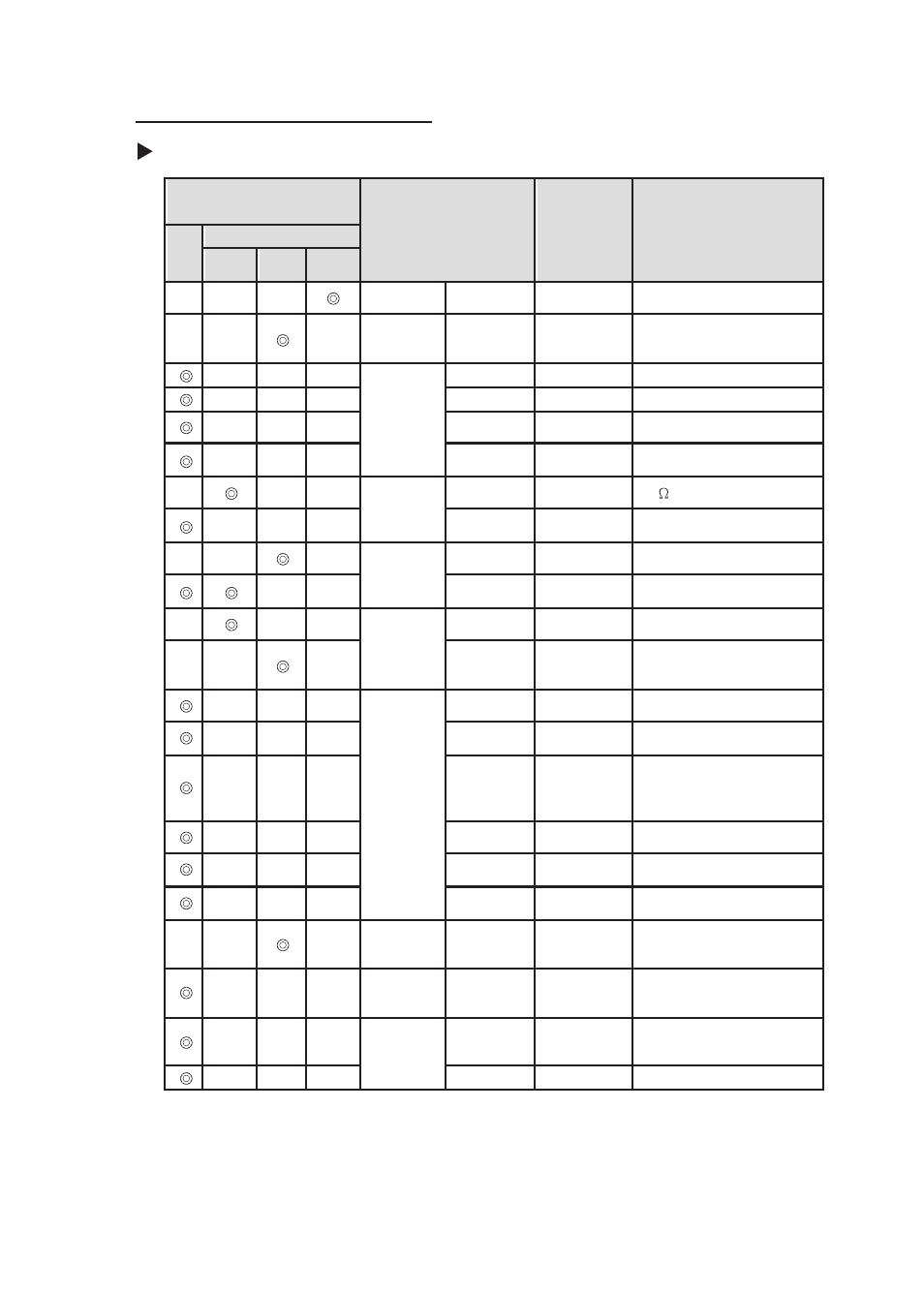

V .Checking and Trouble Shooting

12

Checking Reference

Classification of checks

Checking Item

Checking

Method

Checking Reference

Daily

Periodical

One

month

Three

month

One

year

Marking

Label and the

like

Visual

Existence of label

Installation

Functional

operating

mechanisms

Visual

To be properly adjusted and free

from unusual sounds when

operation

Control/

Switch

Working

Function

Reasonable actuation

Housing

Visual

To be free from cracks

Wiring

Visual

To be free from remarkable

loose or damaged

Cord

Visual,

electricity

To be free from exposure of

conductive wire

Motor

Condition

of insulation

Measure with

resistance tester 1M min

Staining

damage

Decomposition

check

To be free from abnormalities

Braking

Wearing of

brake disc

Decomposition

check

To be free from remarkable wear

and damage

Performance

Visual

Distance to be not more than

1.5% of the lifting speed

Gear

Damage ,

wearing

Decomposition

check

To be free from remarkable wear

and damage

Lubrication

condition

Lubricating

At least once per three months

or 100 working hours for normal

usage

Load Chain

elongation of

link length

Measure

5% minimum

Decreasing of

link diameter

Measure

8% of normal diameter max

Kink

phenomena

run-out of

foundation

Visual

To be free from kink phenomena

Deforming or

corrosion

Visual

To be free from abnormality

Lubrication

condition

Lubricating The chain should be lubricated

every week for normal usage

Surface

condition

Visual

To be free from rust, nicks,

gouges, dents and weld splatter.

Sprocket /

Idle Sheave

Reeving

function

Chain should be reeved properly

through sprocket and idle sheave

for double fall operation

Frame

Housing and

mechanical

components

Visual, function To be free cracks, rupture

harmful deformation

Load Hook

Housing and

mechanical

components

Visual, function

To be free cracks, rupture and

harmful deformation by 5%

maximum

latch

Visual

To be free from deformed