Installation – Kenmore POWER MISER 153.330551 User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Installation

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Space is a space whose volume is not less than 50

cubic feet per 1,000 Btu per hour of the aggregate input rating

of all appliances installed in that space. Rooms communicating

directly with the space in which the appliances arc installed,

through openings not furnished with doors, are considered a

f

»art of the unconfined space

n unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier, etc.),

additional air may need to be provided using the methods

described in Combustion Air and Ventilation for Appliances

Located in Confined Spaces, b.

Combustion Air and Ventilation

for Appliances Located in

Confined Spaces

Confined Space is a space whose volume is less than 50 cubic

feet per 1,000 Btu per hour of the t^regate input rating of alt

appliances installed in that space,

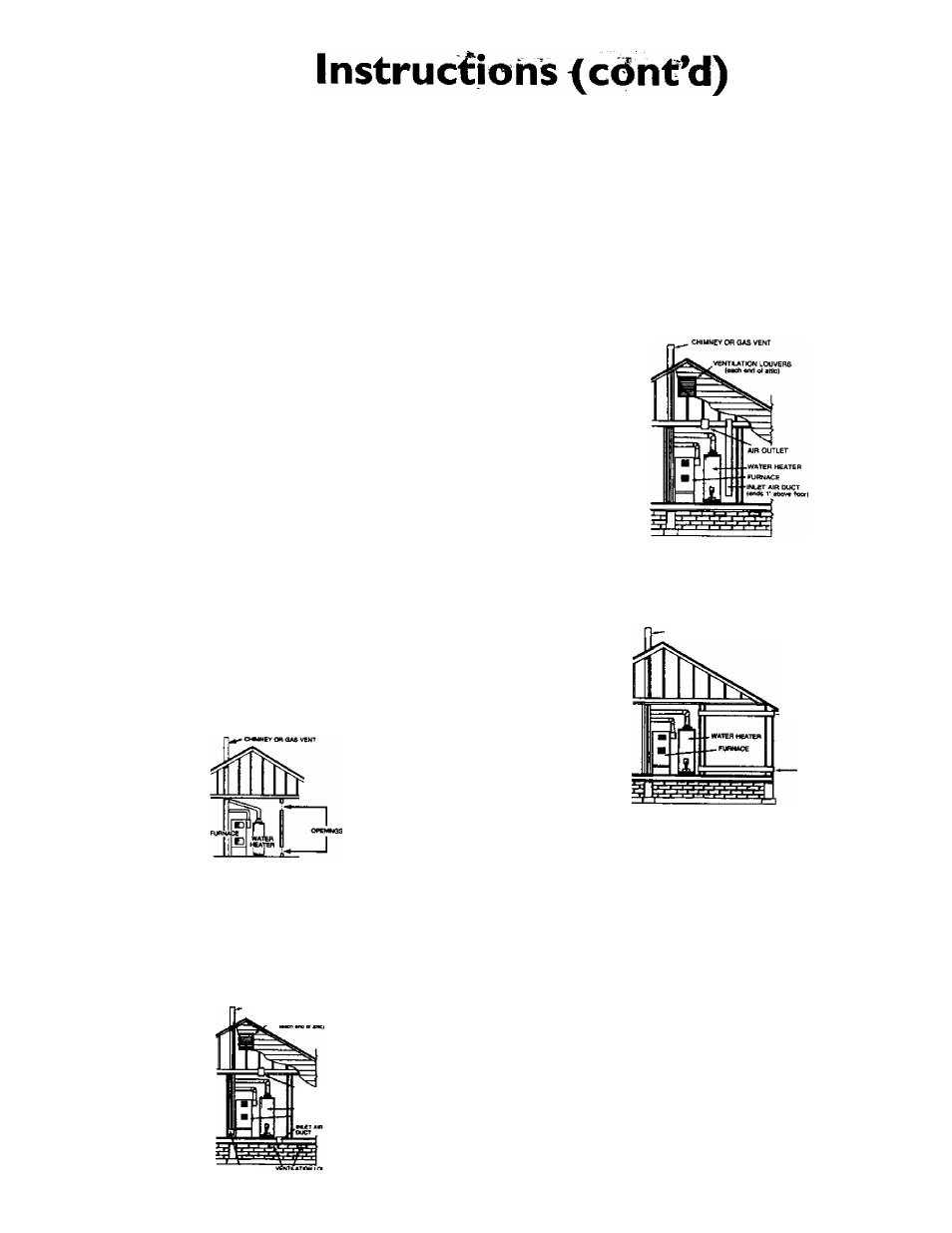

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page 9 Figure 1, and Figure 2 below)

The confined space shall be provided with two permanent

openii^ communicating directly with an additional room(s)

of sufficient volume so that the combined volume of all

spaces meets the criteria for an unconfined space. The total

input of all gas utilization equipment installed in the com

bined space shall be considered in making this determination.

Each opening shall have a minimum free area of one square

inch per 1,000 BTU per hour of the total input rating of ail

gas utilization equipment in the confined space, but not less

than 100 square inches. One opening shall commence within

12" of the top and one commencing within 12" of the bot

tom of the enclosure.

Figure 2

b. A

ll

air

from

outdoors

:

(see Figures 3-5)

The confined space shall be provided with two permanent

openings, one commencing within 12" of the top and one

commencing within 12" from the bottom of the enclosure.

The openings shall communicate directly, or by ducts, with

the outdoors or spaces (crawl or attic) that freely communi

cate with the outdoors.

Ofl OAS VENT

VENTILATtOh LOUVCns

Figure 3

•WATCH НСАТЕЙ

'FgPVWCE

1. When directly communicating with the outdoors, each open-

iim shall have a minimum free area of 1 square inch per 4,000

BTU per hour of total input rating of all equipment in the

enclosure, (See Figure 3.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 BTU per hour of rotal input rating of

all equipment in the enclosure. (See Figure 4.)

Figure 4

3. When communicating with the outdoors through horizontai

ducts, each opening shall have a minimum free area of 1

square inch per 2,000 BTU per hour of total input rating of

all equipment in the enclosure. (See Figure 5-)

^ CHIUMEV OF GA& V&NT

Figure 5

OLTTLCT Alfl DUCT

INLET MR CKJCT

M.T INLET Att

10

4. When ducts are used, they shall be of the same cross-seaional

area as the free area of the openings to which they connect.

The minimum short side dimension of rectangular air ducts

shall not be less than 3". (See Figure 5.)

5. Louvers and Grilles: In calculatiim free area, consideration

shall be given to the blocking effect of louvers, grilles or

screens protecting openings. Screens used shall not be smaller

than

Vi

mesh. If the flee area through a design of louver or

grille is known, it should be used in calculating the size open

ing required to provide the free area specified. If the design

and free area is not known, it may be assumed that wood lou

vers will be 20-25 percent free area and metal louvers and

grilles will have 60-75 percent free area. Louvers and grilles

shall be fixed in the open position or interlocked with the

equipment so that they are opened automatically during

equipment operation,

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of installed

gas utilization equipment.