CAMCORP Blower Package with Roots Blower User Manual

Page 31

8

For your nearest ROOTS Office, dial our Customer Service Hot Line 1 877 363 ROOTS (7668).

O

PERATING

C

HARACTERISTICS

ROOTS

™

rotary blowers and exhausters, as covered in

this manual, are available in basic frame sizes ranging

from 2 inch to 7 inch gear diameter. Various models,

within this gear diameter range, are available with dif-

ferent case lengths to produce reasonable steps in flow

capacity. The shorter case lengths have lower

volumetric capacities, but are capable of operating

against higher pressures. All models are available for

air service and there are specifically designed models

for gas service.

The basic ROOTS

™

rotary lobe blower is a positive

displacement type unit. Flow capacity is determined by

frame size, operating speed and pressure conditions.

It employs two impellers mounted on parallel shafts

rotating in opposite directions within a cylinder closed

at the ends by head-plates. As the impellers rotate,

gas is drawn into one side of the cylinder and forced

out the opposite side. The pressure or vacuum

developed depends on the resistance of the piping

and process system.

The unit is a precision engineered product with very

fine clearances between the rotating impellers and

stationary case. Since there is no actual contact

between these surfaces, internal lubrication is not

required. Clearances are maintained by a pair of

accurately machined timing gears, mounted on the

two shafts extended outside the blower casing.

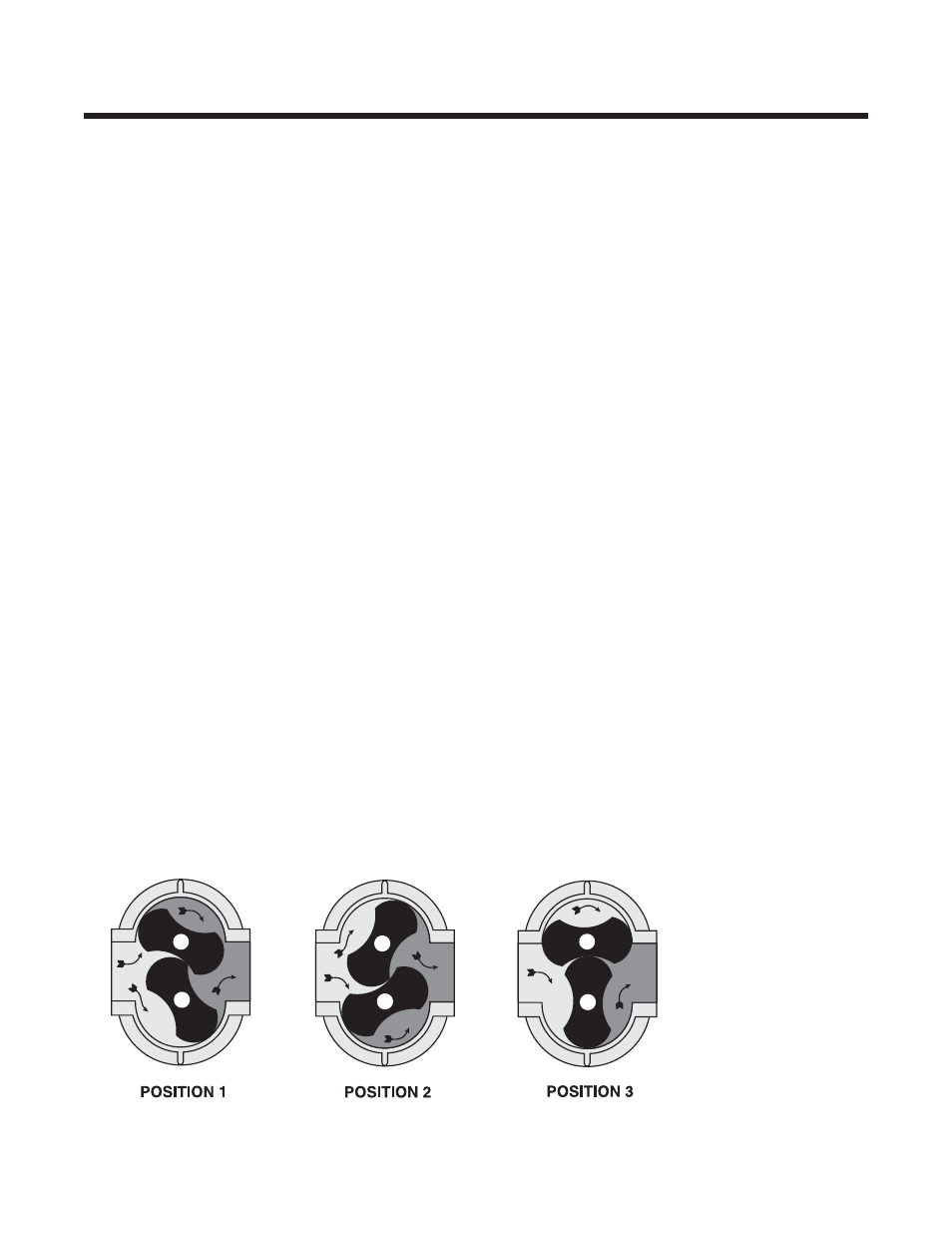

Operation of the familiar basic rotary lobe blower is

illustrated in FIGURE 1, where air flow is left to right

from inlet to discharge with the top impeller rotating

clockwise. In Position 1 it is delivering a known volume

(B) to the discharge, while space (A) between the

lower impeller and cylinder wall is being filled.

Counterclockwise rotation of this impeller then traps

equal volume (A) in Position 2, and further rotation

delivers it to the discharge in Position 3.

One complete revolution of the driving shaft alternately

traps four fixed and equal volumes of air (two by each

impeller) and pushes them through to the discharge.

The volume capacity of a lobe blower operating at a

constant speed therefore remains relatively independ-

ent of reasonable inlet of discharge pressure variations.

To change capacity, it is necessary either to change

speed of rotation or blow off some of the discharge air.

No attempt should ever be made to control capacity

by means of a throttle valve in the intake or discharge

piping. This will not only increase the power load on the

driver, but can also overload and seriously damage the

blower. If a possibility does exist that flow to the blower

inlet may be cut off during normal operation of a

process, then an adequate vacuum relief valve must

be installed near the blower. A pressure type relief

valve in the discharge line near the blower is required

for protection against cut-off or blocking in this line.

Refer to FIGURE 3 for a complete piping schematic.

When a belt drive is installed, blower speed can usually

be adjusted to obtain desired capacity by changing the

diameter of one or both sheaves. In a direct coupled

arrangement a variable speed motor or transmission

is required, or excess air may be blown off through

a manually controlled unloading valve and silencer.

If returned to the blower inlet, the air must be cooled

to 100°F (38°C) through a by-pass arrangement to

maintain acceptable blower temperatures.

Before making any change in blower capacity, or

operating conditions, contact ROOTS for specific

information applying to your particular blower. In all

cases, operating conditions must be maintained within

the approved range of pressures, temperatures and

speeds as stated under LIMITATIONS. The air blower

must not be used to handle liquids or solids as serious

damage to the rotating parts may result.

F

IGURE

1 – F

LOW

T

HROUGH A

B

ASIC

R

OTARY

L

OBE

B

LOWER

A

B

A

B

A

B