Asco valves, Maintenance, Testing of installation – CAMCORP Blower Package with Duroflow Blower User Manual

Page 46: Preventive maintenance s, Causes of improper operation

50-60 Hanover Road, Florham Park, New Jersey 07932

ASCO Valves

Page 3 of 4

Form No.P7050R1

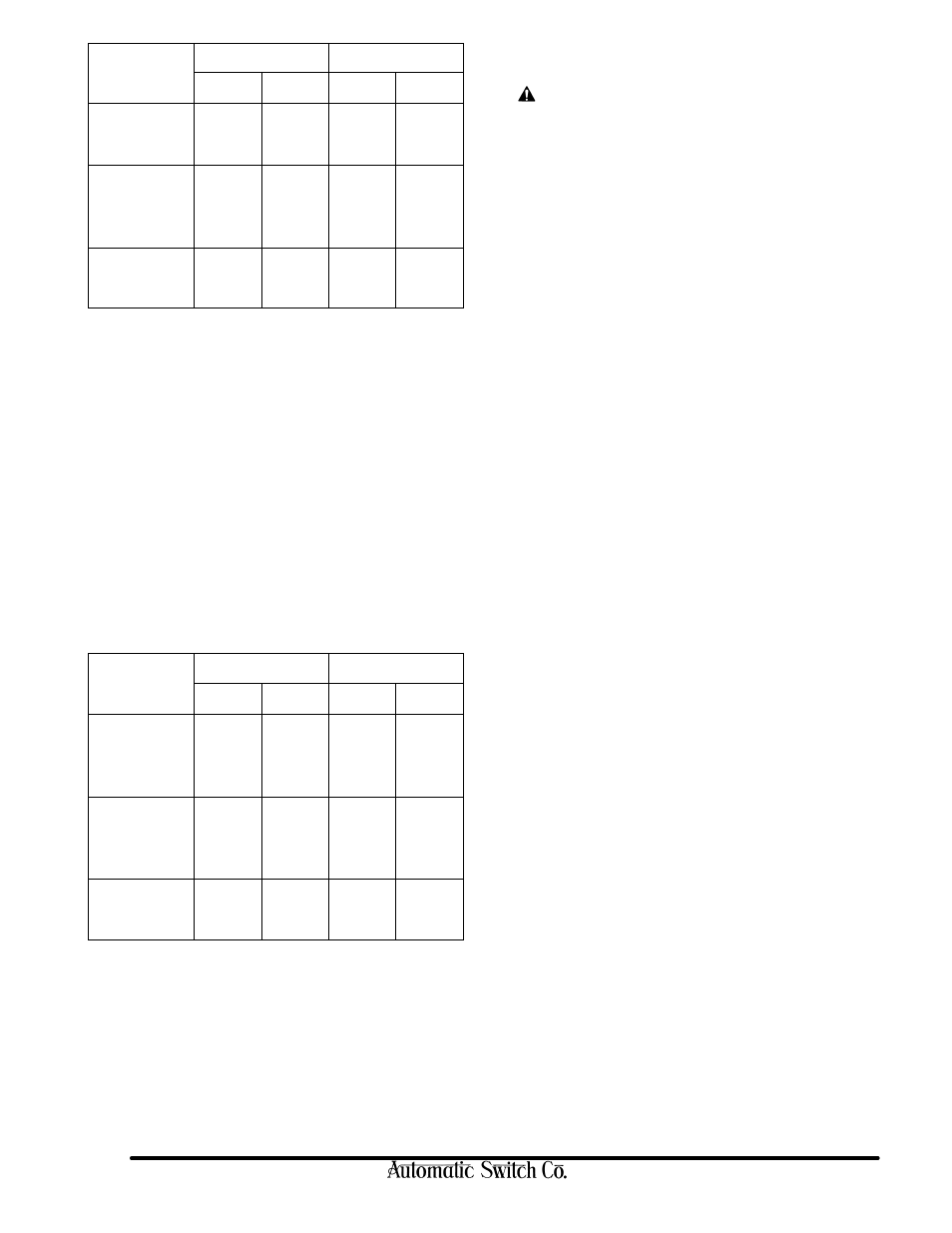

Adjustment

NORMALLY CLOSED

NORMALLY OPEN

Procedures

Switch

Terminal

Test Lamp

On-Off

Switch

Terminal

Test Lamp

On-Off

1. Starting with zero

signal, connect test

lamp to common.

NC

On

(Closed

Circuit)

NO

Off

(Open

Circuit)

2. Apply desired acĆ

tuation signal. Then

back off signal adjustĆ

ing nut until switch

actuates.

NC

Off

(Open

Circuit)

NO

On

(Closed

Circuit)

3. Lower signal to

check reactuation

signal.

NC

On

(Closed

Circuit)

NO

Off

(Open

Circuit)

5. To adjust high signal setting, repeat steps of adjustment in chart above.

6. Cycle between actuation and reactuation signals and make minor

adjustments to nuts as required to achieve the exact signal setting.

7. After settings have been made, make permanent electrical connections.

Adjustment (Signal Setting) of Normally Closed or

Normally Open Switch, Decreasing Signal

(Refer to Figure 3)

1. If the switch is in the line of final application when adjustment (signal

setting) is made, be sure switch can be test operated without affecting

other equipment.

2. On general purpose and watertight constructions, remove switch cover.

3. Turn low signal adjusting nut until low signal setting indictor is fully

down. Then turn high signal adjusting nut until high signal indictor is

fully down. Use a 1/4I wrench for adjusting nuts.

CAUTION: Adjusting nut will turn easily until it hits a stop. Do not

over torque. Over torquing may cause damage.

4. Follow the steps in the chart below to make signal settings. Test one

snap switch at a time. Be sure to start with the high signal side.

Adjustment

NORMALLY CLOSED

NORMALLY OPEN

Procedures

Switch

Terminal

Test Lamp

On-Off

Switch

Terminal

Test Lamp

On-Off

1. Starting with initial

signal above desired

actuation setting,

connect test lamp to

common.

NC

Off

(Open

Circuit)

NO

On

(Closed

Circuit)

2. Decrease signal to

desired

actuation.

Then advance adjustĆ

ing nut until switch

actuates.

NC

On

(Closed

Circuit)

NO

Off

(Open

Circuit)

3. Increase signal to

check reactuation

signal.

NC

Off

(Open

Circuit)

NO

On

(Closed

Circuit)

5. To adjust low signal setting, repeat steps of adjustment in chart above.

6. Cycle between actuation and reactuation signals and make minor

adjustments to nuts as required to achieve the exact signal setting.

7. After settings have been made, make permanent electrical connections.

Testing of Installation

If the adjustment of the switch has been made outside of the line of final

application, the switch should be retested when installed in the line of final

application. Follow adjustment instructions. Be sure switch can be test

operated without affecting other equipment.

MAINTENANCE

WARNING: To prevent the possibility of personal

injury or property damage, turn off electrical power and

depressurize switch unit before inspection or removal.

IMPORTANT: Switch is not field repairable. The switch must be returned

to the factory (Automatic Switch Company, Florham Park, New Jersey) or

serviced only by an authorized factory representative. Address all service

inquiries to Automatic Switch Company, 50-60 Hanover Road, Florham

Park, New Jersey 07932, Valve Service Department. The only maintenance

which may be performed on the switch is changing the setting of the

adjusting nuts and replacement of the transducer unit. Replacement of

transducer should be done only if external leakage is evident.

Preventive Maintenance

S

While in service, operate the switch (cycle between desired signals) at

least once a month to insure proper operation. If necessary, electrical

wiring and pipe connection should be made so that switch can be test

operated without affecting other equipment.

S

Periodic inspection of the switch, external surfaces only, should be

carried out. Switch should be kept clean and free from paint, foreign

matter, corrosion, icing, and freezing conditions.

S

Keep the medium entering the transducer as free as possible from dirt

and foreign material.

Causes of Improper Operation

Switch will not actuate or actuates and reactuates undesirable.

S

Incorrect Electrical Connection: Check leads to switch. Be sure they

are properly connected. Switch is marked NO for Normally Open, NC

for Normally Closed and C for Common.

S

Faulty Control Circuit: Check electrical power supply to switch. Check

for loose or blown fuses, open-circuited or grounded wires, loose

connections at terminal block or switch. See nameplate for electrical

rating and range.

S

Incorrect Adjustment: Check adjustment nuts for proper setting. Refer

to adjustment instructions.

S

External Leakage: Check to see that bolts (4) holding transducer to

pressure switch are properly torqued to 80 ± 10 in-lbs [9,0 ± 1,1 Nm].

If bolts are tight and leakage is still evident, replace transducer. Refer

to paragraph on Assembly of Switch Unit and Transducer Unit.

S

Excessive Vibration or Surges Causing Switch to Actuate and

Reactuate: Check for fluctuations in system and install pressure surge

suppressor. Check switch mounting and be sure there is no excessive

vibration.

S

Incorrect Pressure: Check pressure in system with suitable pressure

gage. Pressure must be within range specified on nameplate.

S

Incorrect Temperature: Check temperature in system with suitable

thermometer. Temperature must be within range specified on

nameplate. Check location of capillary and bulb for incorrect mounting.

Refer to paragraphs on Installation of Temperature Transducers.

If the operation of the switch cannot be corrected by the above means, the

entire switch unit should be replaced or an authorized factory representative

consulted.

FOR SERVICE, REPLACEMENT, OR NEW TRANSDUCER

Consult Factory, or Authorized Factory Representative or Distributors

ORDERING INFORMATION

For Two-Stage Fixed Deadband Switch or New Transducer

When Ordering, Specify Catalog Numbers, Fluid, Pressure Range,

Temperature Range, Serial Numbers, and Proof

Pressure or Rated Overrange Temperature.

NAMEPLATES ARE LOCATED ON SWITCH COVER

AND BOTTOM OF TRANSDUCER.