Asco valves – CAMCORP Blower Package with Duroflow Blower User Manual

Page 45

50-60 Hanover Road, Florham Park, New Jersey 07932

ASCO Valves

Page 2 of 4

Form No.V7050R1

Piping/Tubing (Pressure Transducer)

Adequate support of piping and proper mounting of switch should be made

to avoid excessive shock or vibration. To minimize the effect of vibration on

a switch, mount perpendicular to vibration. Connect piping or tubing to

switch at base of transducer. It is recommended that flexible tubing be used

whenever possible. Apply pipe compound sparingly to male pipe threads

only. If applied to female threads, it may enter the transducer and cause opĆ

erational difficulty. Avoid pipe strain on switch by properly supporting and

aligning piping. When tightening pipe, do not use switch as a lever. Wrenches

applied to transducer body or piping are to be located as close as possible to

connection point.

IMPORTANT: For steam service, install a condensate loop (pigtail or steam

syphon tube) directly into the pressure transducer.

CAUTION: To avoid damage to the transducer body, DO NOT OVERTIGHĆ

TEN PIPE CONNECTIONS. If TEFLON* tape, paste or similar lubricant

is used, use extra care due to reduced friction.

IMPORTANT: To eliminate undesirable pressure fluctuations in the

system, install a surge suppressor.

Wiring

Wiring must comply with local codes and the National Electrical Code. The

general purpose switch enclosure is provided with a 7/8I diameter hole to

accommodate 1/2I electrical hub or connector. The watertight switch

enclosure has a 1/2I conduit hub. It is recommended that a flexible conduit

connection be used. If rigid conduit is used, do not consider it or use it as a

means of supporting (mounting). Use No. 14 AWG copper wire rated for

60_C minimum. Electrical connections are .187I (3/16) spade type quick

connect terminals. Snap switches accept MOLEX INCORPORATED's

connector (Order No. 05-06-0304) and connector housing (Order No.

06-02-3031).

IMPORTANT: Electrical load must be within range stated on nameplate.

Failure to stay within the electrical range of the switch rating may result in

damage to or premature failure of electrical switch.

CAUTION: Do not exert excessive screw driver force on snap switch when

making terminal connections. When connections are made, be sure there is

no stress on the wire leads. Either condition may cause malfunction of

switch.

ELECTRICAL RATINGS

Switch

Unit

Ratings for Limit Controls and

Pressure Operated Switches

Ratings for Industrial Controls

and Temperature Indicating and

Regulating Equipment

Standard

Switch

Rating

2 Amps Res., 125/250 VAC

1/8 HP 125 VAC

1/4 HP 250 VAC

1/2 Amp Res., 125 VDC

1/4 Amp Res., 250 VDC

10 Amps Res., 125/250 VAC

1/3 HP 125/250 VAC

1/2 Amp 125 125 VDC

1/4 Amp 250 VDC

125 VA PILOT DUTY 120/240 VAC

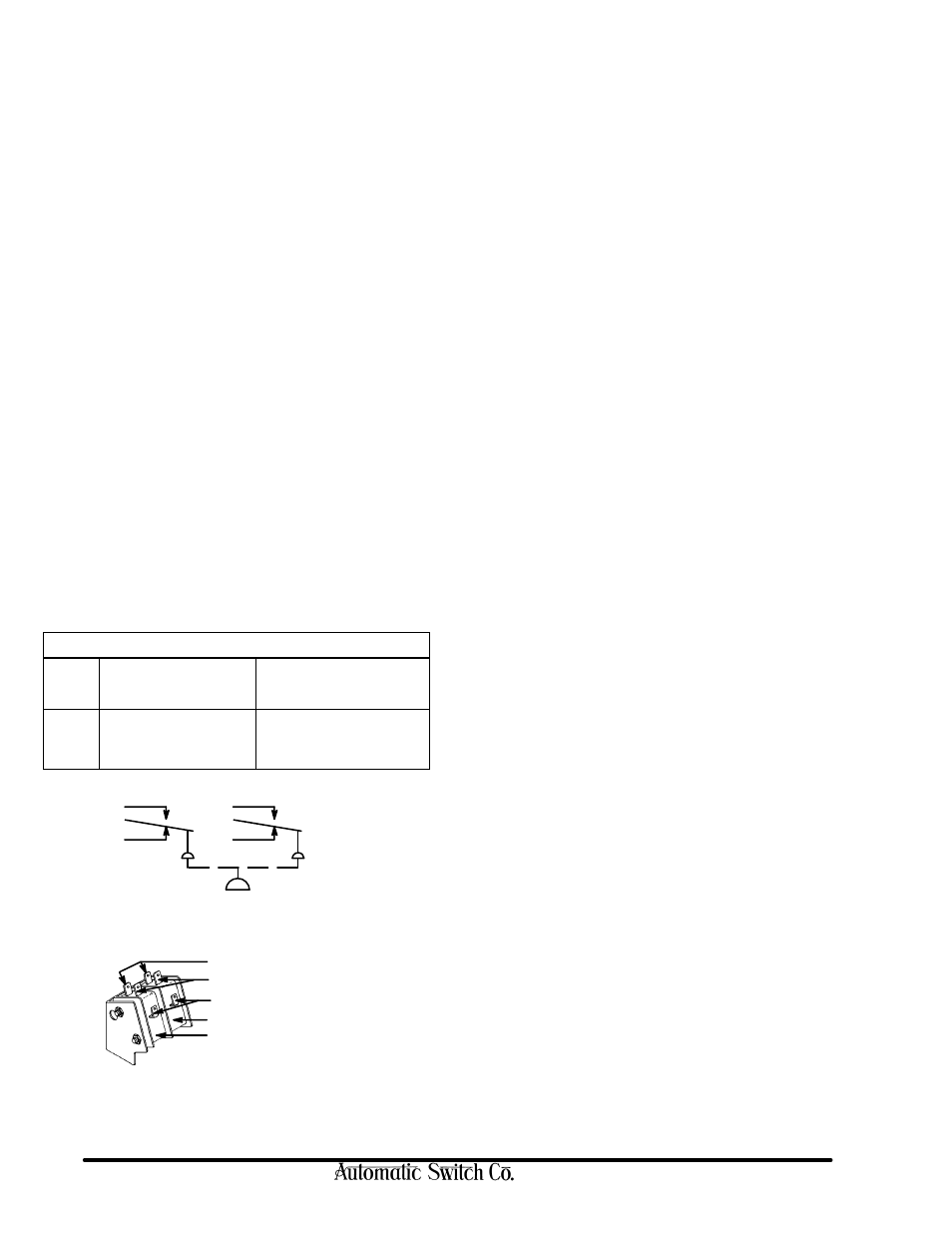

N.O.

N.C.

C

N.O.

N.C.

C

normally open contacts

normally closed contacts

common contacts

high signal setting (right)

low signal setting (left)

SCHEMATIC

DPDT

ELECTRICAL TERMINALS

Electrical terminals are .187

I

spades arranged as:

*DuPont's Registered Trademark

INSTALLATION OF TEMPERATURE TRANSDUCERS

Direct Probe

The direct probe (local) temperature transducer is provided with 1/2I NPT

connection. When installing, do not use switch unit as a lever for tightening.

Use wrenching flats provided at base of transducer for tightening.

Capillary and Bulb

The capillary and bulb (remote) temperature transducers are provided with

a length of capillary and a 3/8I diameter sensing bulb.

CAUTION: Do not bend capillary at sharp angles. For proper operation, be

sure sensing bulb is completely immersed in fluid and not in contact with

heating element or anything that would directly affect the temperature of the

fluid being sensed.

Thermal Well (Optional Feature)

A thermal well may be used for capillary and bulb (remote) or direct probe (local)

temperature transducers. The thermal well affords protection for the sensing

bulb and allows removal of the sensing bulb while maintaining a pressure tight

vessel. When installing sensing bulb in thermal well, be sure that it is fully

inserted. Where a thermal well already exists, jam nuts may be obtained to adapt

the capillary and bulb to the existing thermal well. The existing thermal well must

be for a 3/8I diameter sensing bulb.

Union Connector (Optional Feature)

A union connector will allow direct mounting of the sensing bulb in the fluid

being controlled. Install union into piping connection before tightening

union onto bulb. For maximum performance, the bulb should be inserted in

the union connection so that the end of the sensing bulb is even with the end

of the union connector nut. Do not apply excessive torque when

tightening union connector nut.

Adjustment (Signal Setting) of Two-Stage Fixed

Deadband Switch

When facing switch in the upright position, the adjusting nut on the highest

point controls the high signal setting. The adjusting nut at the lowest point

controls low signal setting (Refer to Figure 3). To make adjustments, a 1/4I

wrench and a pressure or temperature gage (within suitable range) are

required. If electrical connection (to line of final application) of the switch

is not desirable, a battery-powered test lamp or ohmmeter may be used.

Pressure or temperature range scales may be used for initial signal settings.

These will be accurate within 5%. Adjust switch until pointer is in the middle

of the solid red line below the desired range. For exact signal settings,

proceed as follows:

Adjustment (Signal Setting) of Normally Closed or

Normally Open Switch, Increasing Signal

(Refer to Figure 3)

1. If the switch is in the line of final application when adjustment (signal

setting) is made, be sure switch can be test operated without affecting

other equipment.

2. On general purpose and watertight constructions, remove switch cover.

3. Turn high signal adjusting nut until high signal setting indictor is fully

up. Then turn low signal adjusting nut until low signal setting indicator

is fully up. Use a 1/4I wrench for adjusting nuts.

CAUTION: Adjusting nut will turn easily until it hits a stop. Do not

over torque. Over torquing may cause damage.

4. Follow the steps in the chart below to make signal settings. Test one snap

switch at a time. Be sure to start with low signal side.