Battery maintenance – C&D Technologies RS-2061 Standby Batteries for Renewable Energy Applications User Manual

Page 13

Monthly battery inspection

Should include the following:

•

End of charge voltage measured at battery terminal

•

End of discharge voltage measured at the battery

•

General appearance and cleanliness of battery, battery rack and battery area

•

Charging current and voltage

•

Electrolyte levels (flooded only)

•

Cracks in cell containers or leakage of electrolyte

•

Any evidence of corrosion at cell terminals, connectors or racks

•

Ambient temperature and condition of ventilation equipment

•

Pilot-cell voltage, electrolyte temperature (flooded only)

•

Record findings clearly and date entries

Quarterly battery inspection

Should include the monthly observations, plus:

•

End of charge voltage of every cell and battery terminal voltage measured at battery

•

End of discharge voltage of every cell and battery terminal voltage measured at battery

•

Temperature of electrolyte in representative cell(s), typically one cell/tier distributed

throughout battery

Annual battery inspection

Should include the following the quarterly observations, plus:

•

Inter-cell / inter-unit connection integrity, measured with DLRO

•

Record findings clearly and date original and copies

•

Retorque to specified value:

Battery Maintenance

Hydration

A battery, which has been over-discharged and left in a discharged condition without immediate recharge,

is subject to terminal damage known as “hydration.” This is a phenomenon in which the specific gravity of

the electrolyte has been reduced to a level so low that it permits the lead components to dissolve into the

electrolyte, totally destroying the cells. As a result, short circuits become so extensive that is almost impossible

to keep the cells charged. Finally, the cells experience total short circuit failure.

Hydration can be avoided by the use of low-voltage cut-out devices which disconnect battery from load after

the battery, discharged at its specified load current, reaches its designed cut-off voltage.

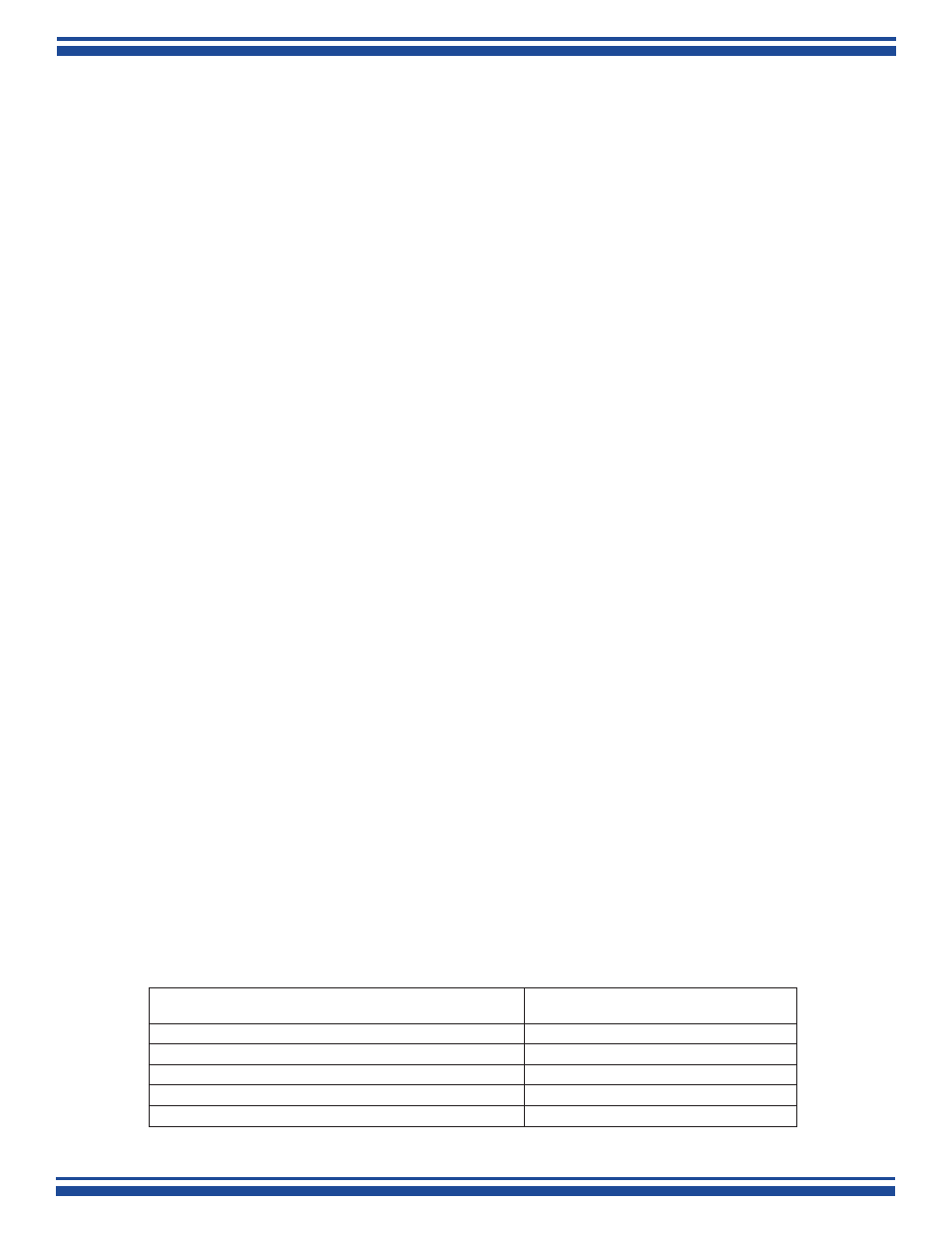

CPV 360, 430, 550, 660, 780, 890, 1000, 1100,

1220, 1330, 1440, 1880 & 2030

150 in-lbs

17 N-m

CPV 1550, 1660, 1770, 2190, 2340, 2500

100 in-lbs

11 N-m

VRS12-33 & 50

30 in-lbs

3.5 N-m

VRS12-75, 88, 100

110 in-lbs

12.4 N-m

D, K, L-CPS

100 in-lbs

11 N-m

VRS12-155F, 175F, 215F

110 in-lbs

12.4 N-m

Model

Re-Torque Value

RS02061/0514/CD

13

www.cdtechno.com