5 module assembly adjustments, Examples of module assembly issues – C&D Technologies RS-2044 msEndurII Series User Manual

Page 25

RS02044/1114/CD

25

www.cdtechno.com

9.5 Module Assembly Adjustments

A module assembly that has been incorrectly assembled in the field should be adjusted to ensure

all cells, cell side restraint plates, cell spacer plates, connectors and hardware are properly aligned

and installed.

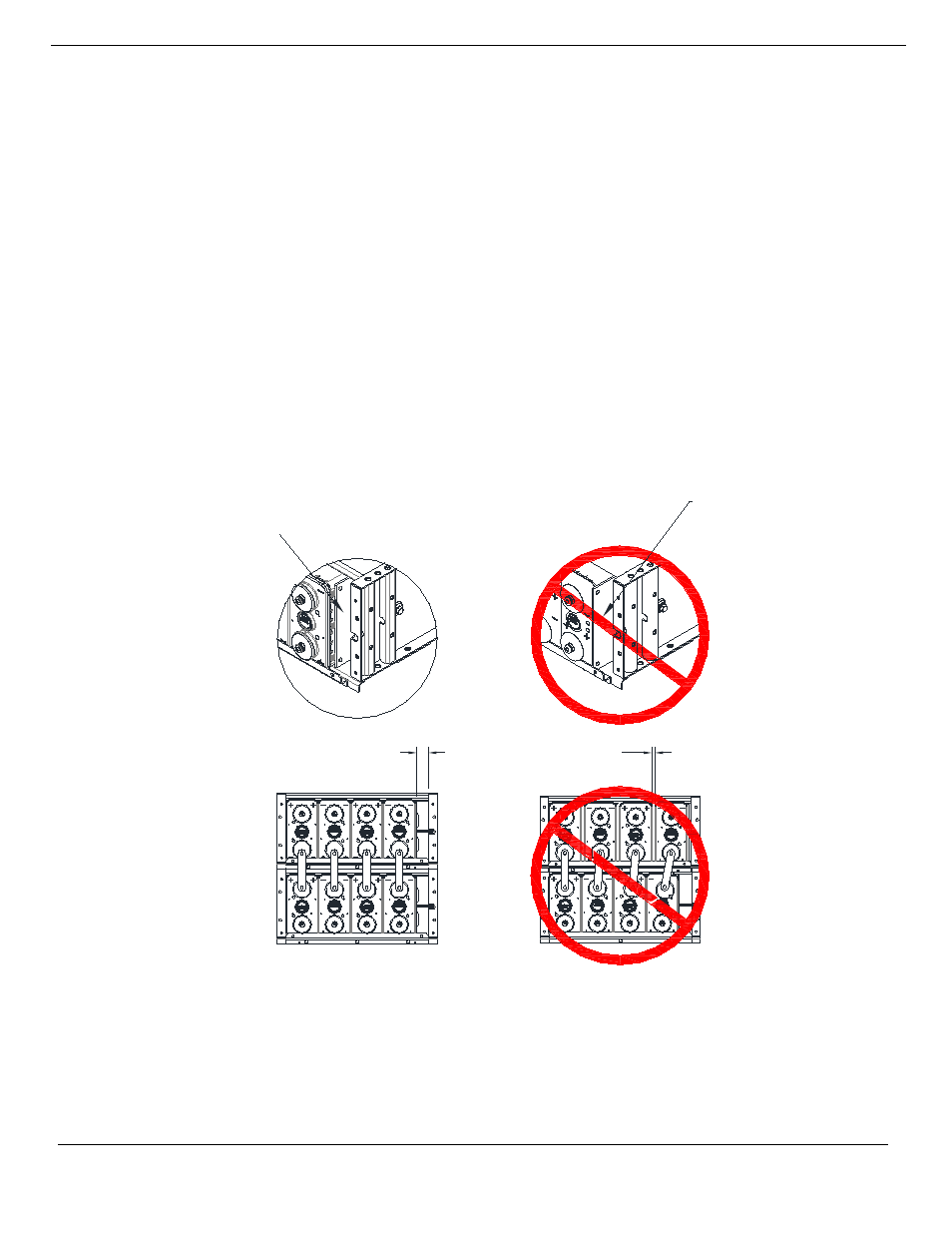

Common assembly issues (see Figure 9-1):

1. Connectors not plumb and vertical (due to large cell cover spacing) and the GAP is not

within specifications noted in Table 2 in Appendix C

2. Side restraint bolts not straight

3. Cell side restraint plates and/or cell spacer plates extending beyond the lower lip of the

module

4. Cell side restraint plates contacting the jar/cover seal of the cell (too far forward)

Figure 9-1 Module Assembly Issues

PROPER CELL SPACING

AND CONNECTORS

STRAIGHT

AND VERTICAL

IMPROPER CELL

COVER SPACING

AND CONNECTORS

ANGLED

SIDE RESTRAINT

PLATE

PROPER

LOCATION

SIDE RESTRAINT

PLATE

IMPROPERLY

ON JAR/COVER

JOINT

EXAMPLES OF

MODULE ASSEMBLY

ISSUES

CELL

COVER

SPACING

GAP

"Cell side

restraint plate

improperly

seated; needs

to be pushed

towards back