AAF International Type N RotoClone User Manual

Page 3

3

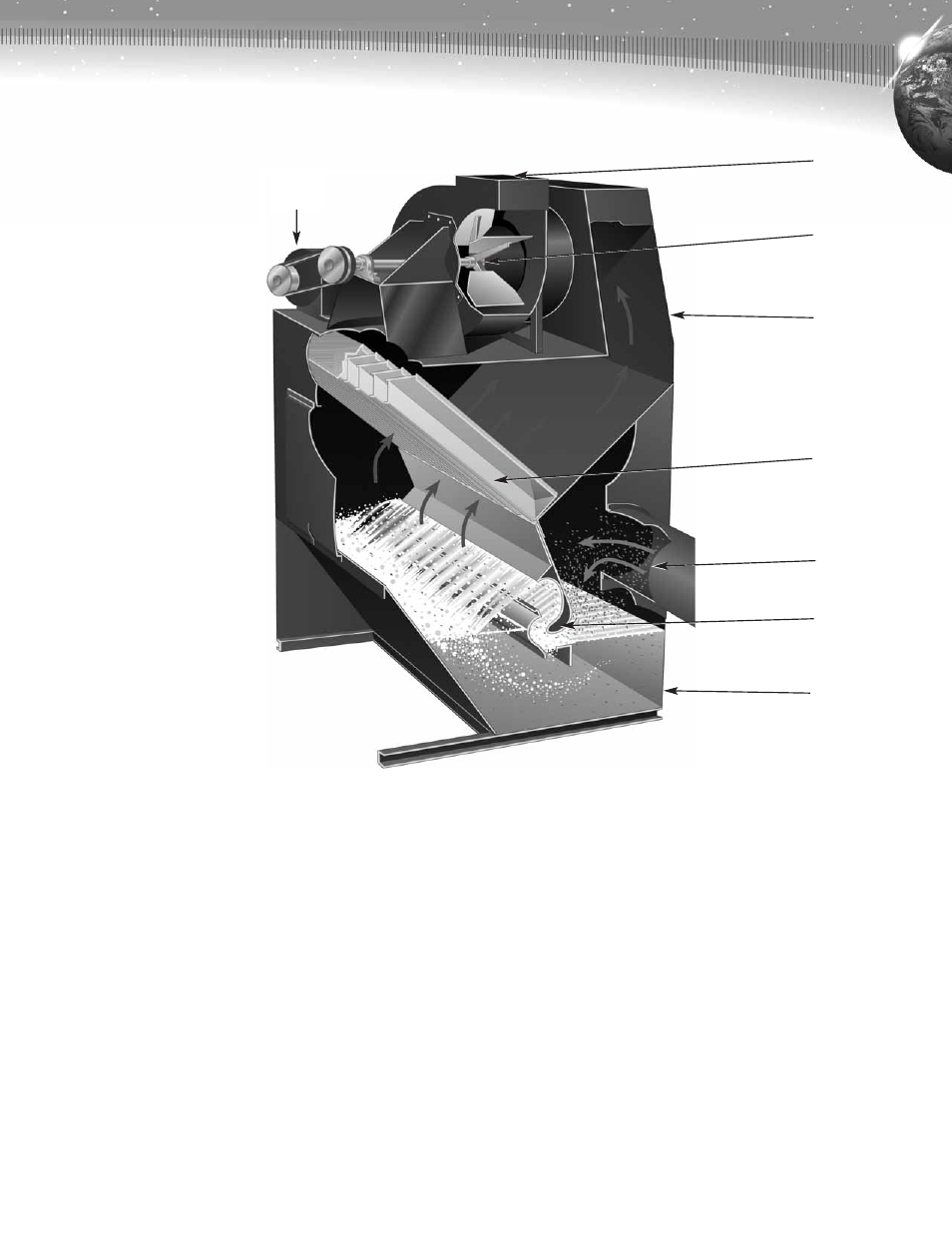

Motor &

Drive

Figure 2. Cutaway section of typical Type N RotoClone Design 2 and 3 size 1

1

⁄

2

thru 6.

Clean Air

Discharge

Exhauster

Clean Air

Transition

Water

Eliminators

Dirty Air Inlet

Impellers

Hopper

3. For RotoClone Sizes 1

1

⁄

2

thru 6 which are not shipped with

exhausters or for all RotoClone Sizes 8 and larger, three-inch

sealing tape is furnished. This tape seals the

5

⁄

8

inch nominal gap

between the clean air transition and the exhauster inlet.

4. RotoClones, Sizes 8 thru 48 are shipped disassembled in major

subassemblies; RotoClone, clean air transition, motor, drive, and

exhauster. Necessary gasket material for the flange between the

RotoClone and transition section and the three-inch sealing tape

noted above are packed in a box with bolts.

5. If necessary, Sizes 16 thru 48 can be shipped with the collecting

section and hopper section disconnected.

Field assembly of collecting section and hopper section will require

the following:

a. Install gaskets on top of hopper external flange.

b. Set collecting section in place so its bolting flange matches

hopper flange. Lower carefully, watching for interference between

intermediate sheets (lower section of curved entrainment baffles)

and impellers. Walls of interior center section, formed by the two

intermediate sheets must be inside impeller bolting surface

(Figures 1 and 3).

c. Bolt outside flanges of collecting section and hopper section.

d. Bolt impellers to intermediate sheets. Before tightening, entering

edge (Figure 1) of impellers must be in a straight line. Impellers

were installed in the hopper section and aligned at the

factory. Each impeller section is matched-drilled with holes in

intermediate sheet. Pull these bolts tight and check alignment

before tightening remainder of bolts through slotted holes in

impellers and drilled holes in intermediate sheets.