AAF International PORTA Scrubber User Manual

Page 7

5.6 General System Maintenance

Ducts, external PORTA-Scrubber surfaces, latches, blower, and

other system infrastructure should be checked at least every 6

months. Internal surfaces shall be examined whenever filters are

replaced. Examine all components for the following:

5.6.1 Cleanliness: Sweep and vacuum all standing dust or

dirt in the system. If using cleaning solvents, be mindful of the

impact of solvents on the performance and life of the chemical

media and take appropriate precautions to protect the system.

5.6.2 Water: The system should be completely dry at all times.

The presence of standing water, condensation, or dampness

is detrimental to the performance and life of the system.

Determine and remove the cause for the presence of water in

the system, dry the system, and examine all components for

the presence of molds and other biological growth. Remove

all contamination, clean and sterilize as necessary.

5.6.3 Filter System Integrity: Ensure that the unit contains the

appropriate filter elements, both particulate and gas-phase, and

that these elements are correctly installed. Check for missing or

improperly installed components and review the system seals.

Check for air leaks at joints and seams and replace gaskets,

worn hardware, and seal with caulk as necessary.

5.6.4 Duct and System Integrity: Examine the entire system

to ensure that contaminated air cannot leak around the filter

system. Check all perimeter seals and repair as necessary.

5.6.5 Corrosion: If metal components are corroded repair the

corrosion and provide protective coatings as necessary. Be

mindful of the impact of painting on the performance and life

of the chemical media, and take appropriate precautions to

protect the system. Determine the source of the corrosion

and rectify.

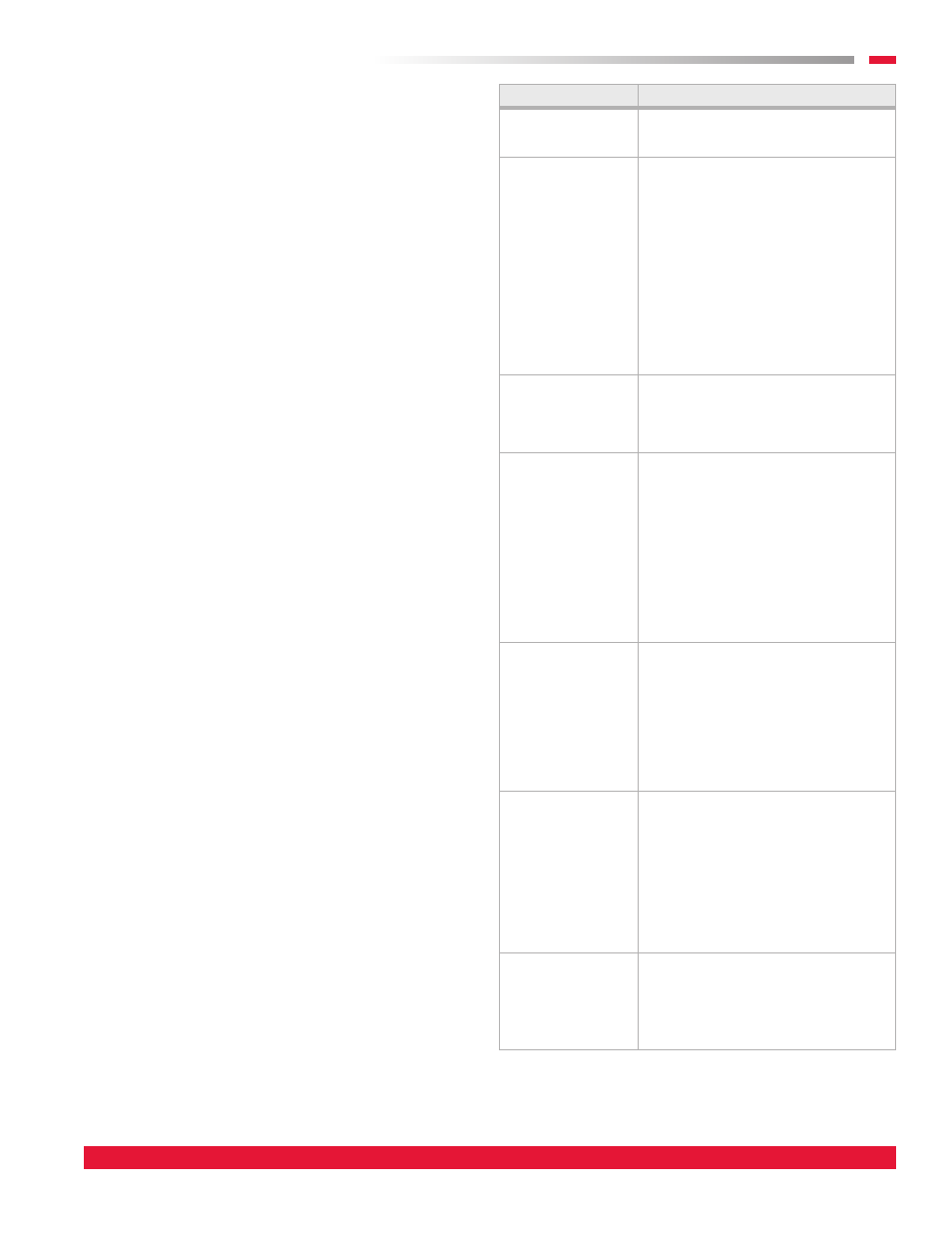

6.0 Troubleshooting

Potential problems and causes listed are in no order of

importance or priority. The causes are only a list of the most

common items to check to correct a problem. If you find the

cause of a problem, DO NOT assume it is the only cause of that

problem. Different problems can have the same cause.

Problem

Cause

Odors and Smells

1. Chemical media is spent.

2. Missing or damaged filters.

3. Incorrect media installed.

Airflow (CFM) Too Low 1. Blower wheel turning in wrong direction.

2. Actual system static pressure is higher

than expected.

3. Motor speed (RPM) too low.

4. Dampers or valves not adjusted properly.

5. Leaks or obstructions in duct work.

6. Filters dirty.

7. Inlet and/or discharge guards are clogged.

8. Duct elbow too close to blower discharge.

9. Improperly designed duct work.

10. Condensation of moisture blinding the

particulate and/or chemical media.

11. Presence of moisture in the filters

combined with freezing temperatures can

cause the filters to become impassible.

Airflow (CFM) Too High 1. Actual system static pressure is lower

than expected.

2. Motor speed (RPM) too high.

3. Filters not in place.

4. Dampers or valves not adjusted properly.

Excessive Vibration

1. Loose mounting bolts, wheel set screws,

taper-lock hubs.

2. Worn or corroded blower wheel.

3. Accumulation of foreign material on

blower wheel.

4. Bent motor shaft.

5. Worn motor bearings.

6. Motor out of balance.

7. Inadequate structural support.

8. Support structure not sufficiently

cross braced.

9. Weak or resonant foundation.

10. Foundation not flat and level.

Motor Overheating NOTE: A normal motor will operate at 174ºF.

1. Actual system static pressure is lower

than expected.

2. Voltage supplied to motor is too high or

too low.

3. Motor speed (RPM) too high or

defective motor.

4. Air density higher than expected.

5. Motor wired correctly or loose wiring

connections.

Excessive Noise

1. Wheel rubbing inside of housing.

2. Worn or corroded blower wheel.

3. Accumulation of foreign material on

blower wheel.

4. Loose mounting bolts, wheel set screws,

or taper-lock hubs.

5. Bent motor shaft.

6. Worn motor bearings.

7. Motor out of balance.

8. Motor bearings need lubrication.

9. System resonance or pulsation.

Fan Doesn’t Operate

1. Motor wired incorrectly or loose wiring

connections.

2. Incorrect voltage supply.

3. Defective fuses or circuit breakers.

4. Power turned off elsewhere.

5. Defective motor

7