Powered collector – Countax D50 User Manual

Page 13

Page 13

Powered Collector

CONNECTION

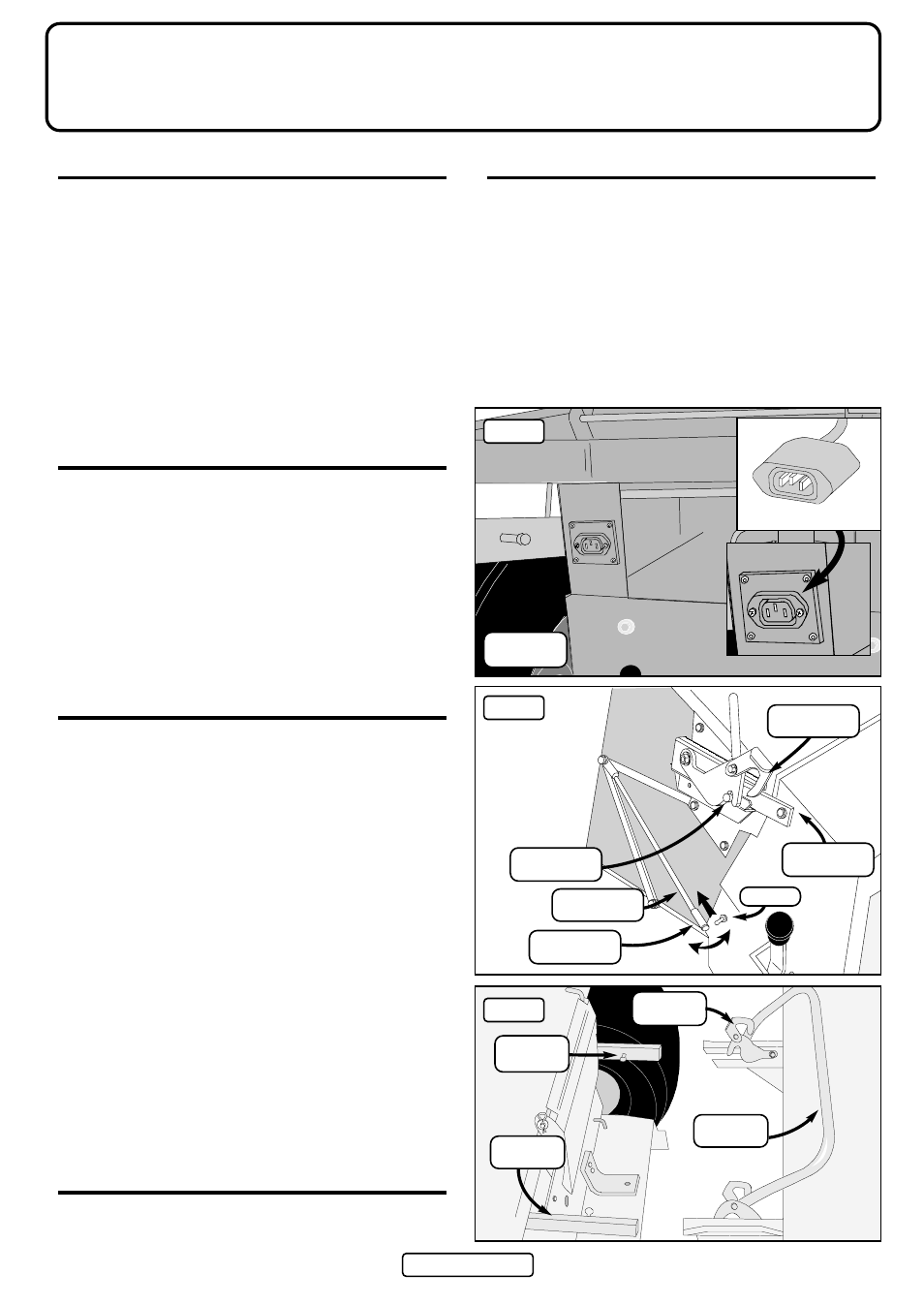

To connect the Powered Grass Collector (PGC) to the D18/50

tractor, ensure both are on an even surface with the locking

levers (fig 3) on the collector facing the lift arms of the tractor.

Move the collector manually to the tractor. Lower the lift arms

using the auxiliary lift switch button (page 4) on the dash

console.

At the end of each lift arm you will find a locating lug. Slide the

channels on either side of the PGC over the lugs but do not

engage the locating lever yet. Ensure that the rubber flap at the

opening of the PGC located on top of the transmission grass

deflector.

INSTALLING THE DRIVE BELT

Place the drive belt over the PTO pulley (beneath the tractor

seat). Standing adjacent to the tractor, extend the belt with both

hands parallel to the ground. Now twist the belt to form a figure

‘8’ – the right hand up and the left hand down. In this position

place the other end of the belt over the Powered Collector pulley.

Be sure that this is installed the right way round otherwise the

brush will work in reverse and collection will be poor! Lock

locating lever (fig 3) over the lift arm lugs. Rotate the locking

clips over lift arm lugs. Connect net empty plug to socket as

shown in fig 1. To disconnect, reverse this procedure.

PTO DRIVE BELT TENSION

Engaging the locating lever tensions the belt which should not be

run too tight – to check the tension there should be a 19mm

deflection with light finger pressure (2Kgs) at a midway point

between PTO pulley and sweeper pulley. It is important after

attaching the sweeper to the tractor to check the belt tension and

adjust this if necessary this must be done before the sweeper is

put into operation and with the sweeper on the ground. With light

finger pressure, 2Kgs (4lbs) there should be a total deflection of

19mm (3/4") at midway point between PTO pulley and the

sweeper pulley. If a spring balance is available a pressure of 4-

5lbs (1.81-2.26Kgs) is required for a deflection of 3/4" (19mm).

If the belt tension is incorrect, it can be adjusted by movement of

sweeper locking levers on the threaded rod. Ensure the lock nuts

are suitably tightened after adjustment. N.B. Do not over-tighten

lock nuts as lever needs to pivot.

TO USE: raise sweeper to transport position. A button on the left

hand side of the console (page 4) raises the Powered Collector to

the transport position. We recommend that you drive to and from

the area to be swept with the Powered Collector in this transport

position and with the PTO disengaged. When you reach the area

to be swept, lower the collector and then engage the brushes by

pushing the sprung PTO lever to the left to release and engage.

LOWER THE COLLECTOR

Using the Auxiliary lift switch on the dash, lower the collector.

REMOVE THE NET

When removing the net, we suggest you employ the assistance of

another person.

1. Partially open the Sweeper net (100mm(4")). Disconnect

opening rod by pulling back on sprung locking tube and

uncoupling from pin (fig 2).

2. Repeat either side.

3. Undo net locking clip (both sides), unhook levers from

locating pins (see fig 2).

4. With either person standing each side of the collector net, slide

the net off the locating arms.

5. Reverse operation for fitting.

fig 1

fig 2

fig 3

Net Locking

Clips

Pin

Locating

Pins

Locking

Tube

Opening

Rod

Locating

Lever

Locking

Clips

Lifting

Arm

Locating

Arms

Net Empty

Socket

Locating

Lug