Cutter - drive belt, Page 12, Engine to cutter drive belt tension – Countax D50 User Manual

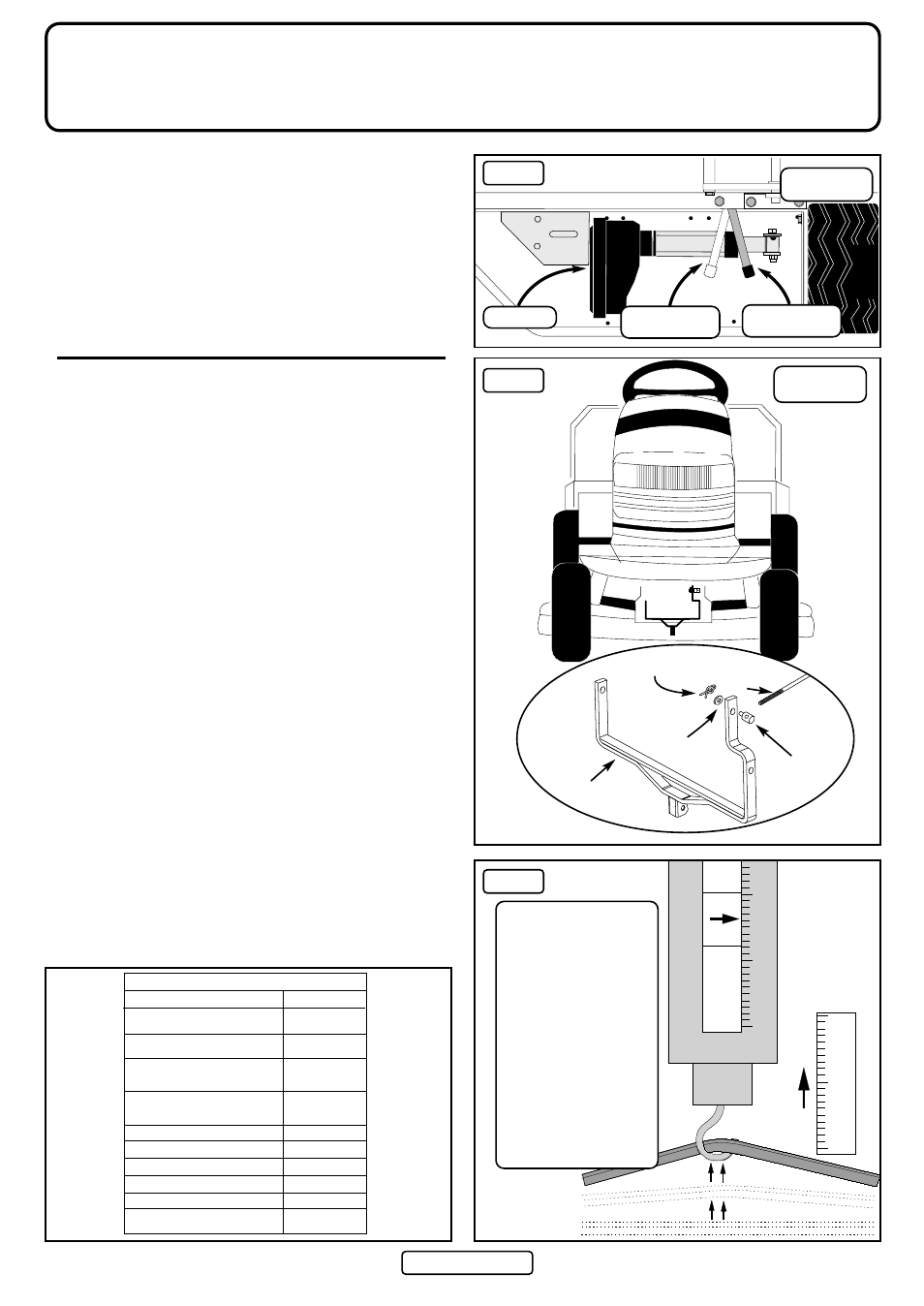

Page 12: Fig 2 fig 3 fig 1

Page 12

Cutter - Drive Belt

Before carrying out tests or adjustments (the problem may be

simpler) – first CHECK the following points:

1. Is the engine to cutter drive belt slipping? Check that the drive

belt tension lever (fig 1) under the left running board is in the

rear (tensioned) position. If not, rectify – this is the most likely

cause.

2. Has debris collected in the cutter deck pulley housing

(page 9)? If so remove the cover and remove the obstruction.

ENGINE TO CUTTER DRIVE BELT TENSION

The correct tension of the cutter drive belt (engine to deck) is

critical. If incorrectly set it can lead to engine damage.

To check the tension, follow this procedure:

1. Put the deck in a middle cutting height (position 5 on the HE

illuminated indicator).

2. Select a midway position on the belt between the front

(electric clutch) pulley and the rear (cutter deck) pulley and

using a spring balance; apply a 2Kg (4 to 5lbs) pull (fig 3).

3. Using a ruler or tape, measure the deflection achieved which

must be 13mm (1/2"). If more, the belt tension must be

increased, if less – decreased.

To correct the tension, follow this procedure:

1. Release the tension on the belt by pulling the belt tension lever

forward (see fig 1).

2. Taking care not to burn yourself on the hot exhaust, locate the

Trunnion at the end of the belt tension rod – lift the bonnet and

look at the front (nearside) close to the exhaust.

3. Remove the spring clip and washer holding the Trunnion in

place on the deck tension cradle (fig 2) and release the

Trunnion so it can be turned.

4. Both the Trunnion and the belt tension rod are threaded. You

increase belt tension by winding the Trunnion towards the end

of the rod and reduce tension by winding in the reverse

direction.

5. Having made the adjustment re-locate and secure the

Trunnion, re-tension the belt with the belt tension lever – then

re-check the belt tension.

Deck Tension

Cradle

Deck Tension

Rod

Trunnion

Washer

Spring Clip

Kg

cm

Specified Belts and Blades

Part No.

Part:

Engine/Deck Belt -

Dayco Super II B56 (Mulcher)

22871200

Deck Internal Drive (Mulcher)

BB112

228000900

Deck Internal Drive (IBS)

BB155

22950200

Mulcher Blades x3

16938100

IBS RH Blade

169381300

IBS LH Blade

169381400

PGC Drive Belt A47

22898000

PTO Drive Belt - Dayco II A98

22950100

Transmission Drive Belts A98

Dayco Super II

2295000

Engine/Deck Belt -

Dayco Super II B57 (IBS)

22940100

-WARNING-

On no account must

the tractor be run with

the engine to cutter

drive belt over-

tensioned as it will

damage the engine.

As any such damage

will not be covered by

your warranty you

may prefer that your

dealer sets the

tension.

fig 2

fig 3

fig 1

De-tensioned

Position

Actuator

Tensioned

Position

Deck

Tension Lever

Deck

Tension Cradle