7 | maintenance – GEA Bock HG34e A User Manual

Page 22

22

D

GB

F

E

96191-11.2014-DGbFE

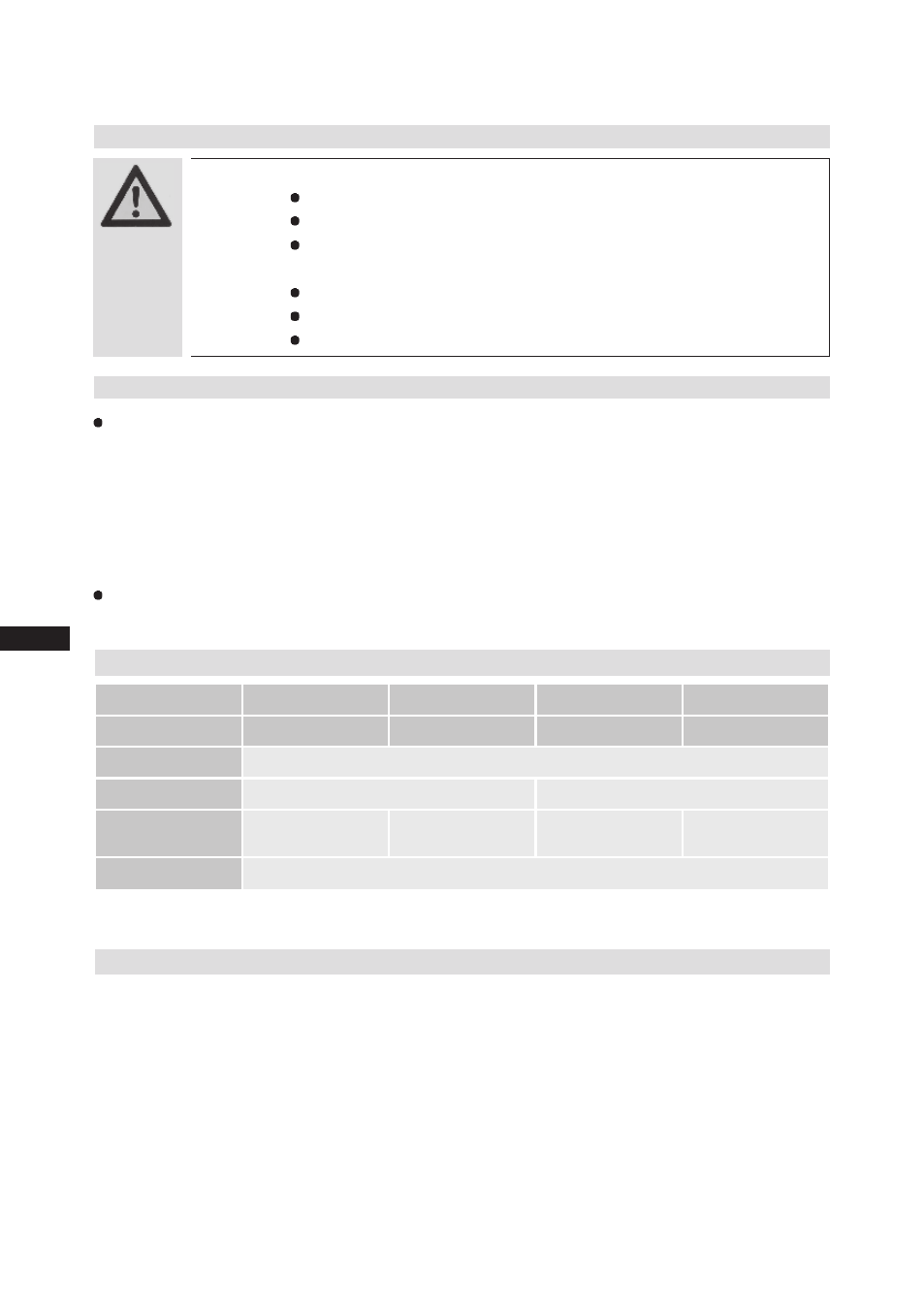

7.1 Preparation

7.2 Work to be carried out

7 | Maintenance

HG34e / ...

215-4(S) A

255-4(S) A

315-4(S) A

380-4(S) A

Designation

Ref. No.

Ref. No.

Ref. No.

Ref. No.

Set gaskets

80582

Valve plate set

80305

80306

Piston/connecting

rod set

80301

80302

80303

80304

Connecting rod set

08422

Oil change: In principle, an oil change is not mandatory if the system is correctly manufactured

and operated.

However, based on decades of experience we recommend that the following oil change/service

work is carried out:

-

First oil change during the first maintenance system.

-

Then after every 10,000 – 12,000 operating hours, though no more than

3 years, cleaning oil and suction filter at the same time.

Annual checks: Oil level, tightness, running noise, pressures, temperatures, function of auxiliary

devices such as a oil sump heater, pressure switch.

Accessories available can be found on the Internet at www.gea.com

7.4 Accessories

Only use original GEA Bock spare parts!

7.3 Spare parts recommendation

WARNING! Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.