4 | compressor assembly – GEA Bock HG7 R134a User Manual

Page 11

D

GB

F

E

11

96182-01.2015-DGbFEI

The

pipe connections have graduated inside diameters so that pipes with

standart millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are rated for maximum

compressor output.

The actual required pipe cross section must be

matched to the output. The same applies for non-return valves.

Fig. 10: graduated

internal diameter

4| Compressor assembly

Rigid

fixed point

Fig. 11

INFO!

For compressors HGX7/2110-4 and HGX7/2110-4 S, solder connections

are mounted to the suction shut-off valve for pipe diameter 64.

Solder connections for pipe diameter 2 5/8“ are enclosed with the

compressor.

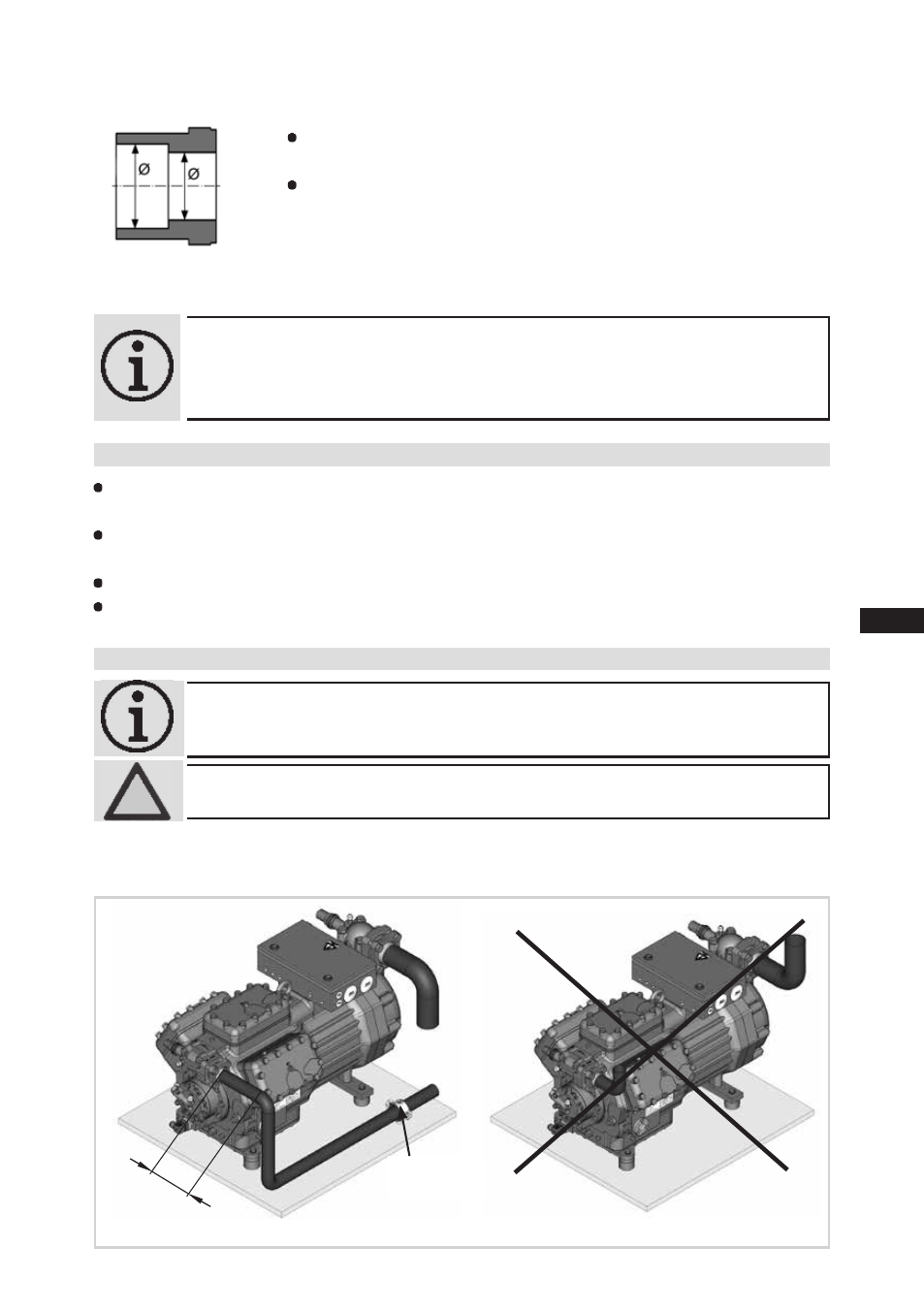

As short as

possible

4.5 Laying suction and pressure lines

INFO!

Proper layout of the suction and pressure lines directly after the

compressor is integral to the smooth running and vibration behaviour

of the system.

ATTENTION! Improperly installed pipes can cause cracks and tears which can

result in a loss of refrigerant.

A rule of thumb:

Always lay the first pipe section starting from the shut-off valve

downwards and

parallel to the drive shaft.

4.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.