2 clamping the torquemaster, Accessories – FRITSCH PULVERISETTE 0 User Manual

Page 35

1.

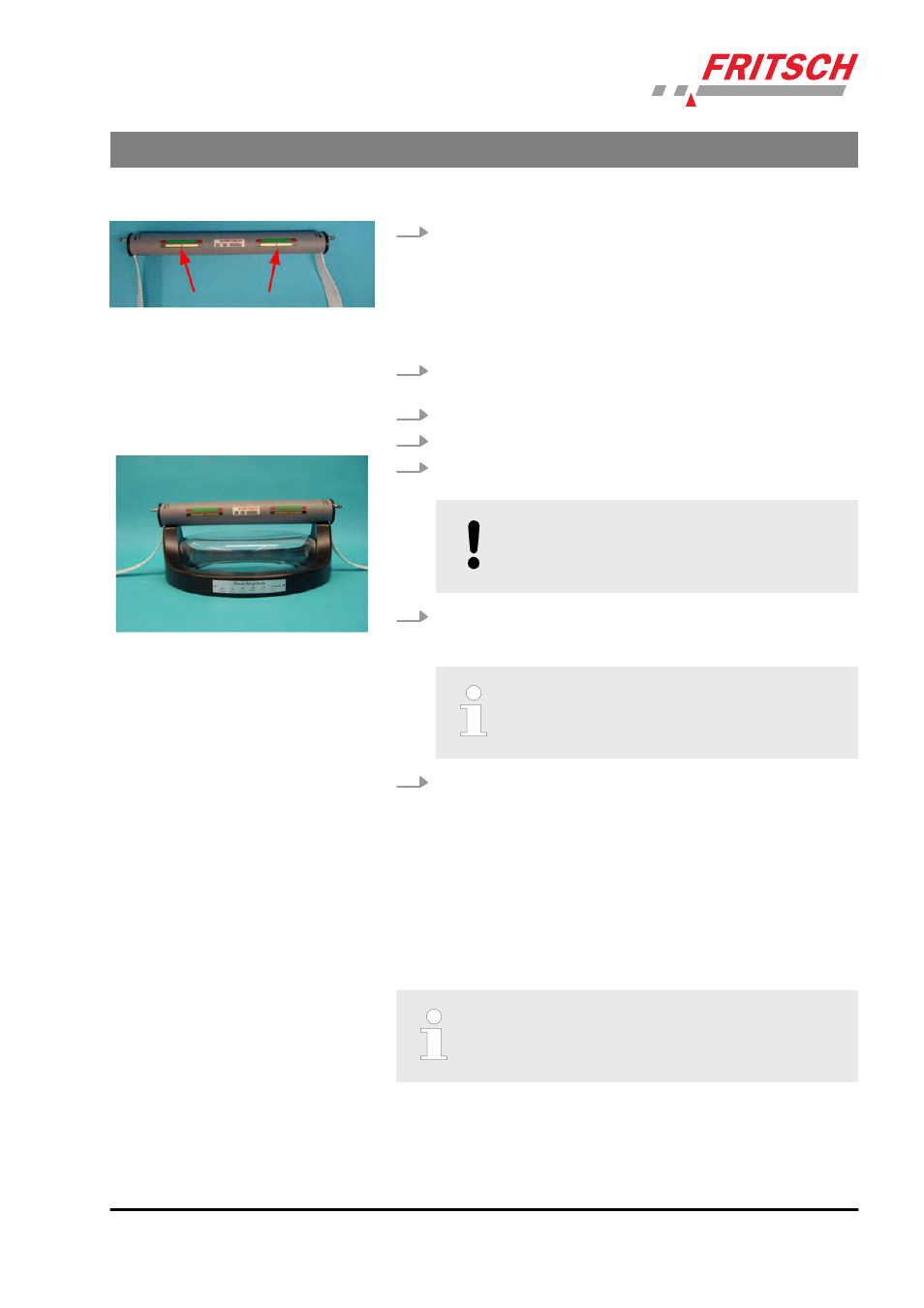

The starting position of the clamping system is the position at

which both indicators are roughly in the centre of the respective

display range.

This position later ensures that sieve stacks of various heights can

be clamped easily, or that there is sufficient space to release the

system, remove it from the sieve stack and place it behind the

device.

2.

Insert the toothed belt in the belt clamping device as described in

Chapter 7.2.1.2 ‘Fitting and clamping the sieves’ on page 26.

3.

Insert the sieve set and pour in the sieving stock.

4.

Fit the TorqueMaster clamping lid.

5.

Place the clamping unit on the clamping lid. The clamping unit

must be fitted as centrally as possible.

NOTICE!

This symmetry is ensured by correctly adjusting and

securing the toothed belt.

6.

Lightly tighten the toothed belts on both sides and move the

clamping lever upwards, as described in Ä Chapter 7.2.1.2 ‘Fitting

and clamping the sieves’ on page 26 under point 9.

Make sure that both indicators remain in their central

position.

7.

The clamping system can now be clamped using the cordless

screwdriver.

7.2.7.2

Clamping the TorqueMaster

Clamping with a cordless screwdriver until it disengages applies a repro-

ducible force of ~ 1 kN to the sieve cover.

Clamping processes during which the friction clutch of the cordless

screwdriver does not disengage (e.g. due to defect, dead battery or

operating error) do not provide the desired clamping force.

The correct clamping force is only achieved if the friction

clutch of the cordless screwdriver triggers during the

clamping process.

Accessories

- 35 -