Maintenance & adjustments, Maintenance – Cub Cadet i1050 User Manual

Page 17

Maintenance & Adjustments

6

1

Maintenance

WARNING! Before performing any mainte-

nance or repairs, disengage the PTO, move the

drive control levers fully outward in the neutral

position, engage the parking brake, stop the

engine and remove the key to prevent unin-

tended starting.

Engine

Refer to the Kohler Owner’s Manual for all engine mainte-

nance intervals, procedures, specifications and instructions.

Changing the Engine Oil

WARNING! If the engine has been recently run,

the engine, muffler and surrounding metal

surfaces will be hot and can cause burns to the

skin. Exercise caution to avoid burns.

To complete an oil change, proceed as follows:

Run the engine for a short time to warm the engine

oil. The oil will flow more freely and carry away more

impurities. Use care to avoid burns from hot oil.

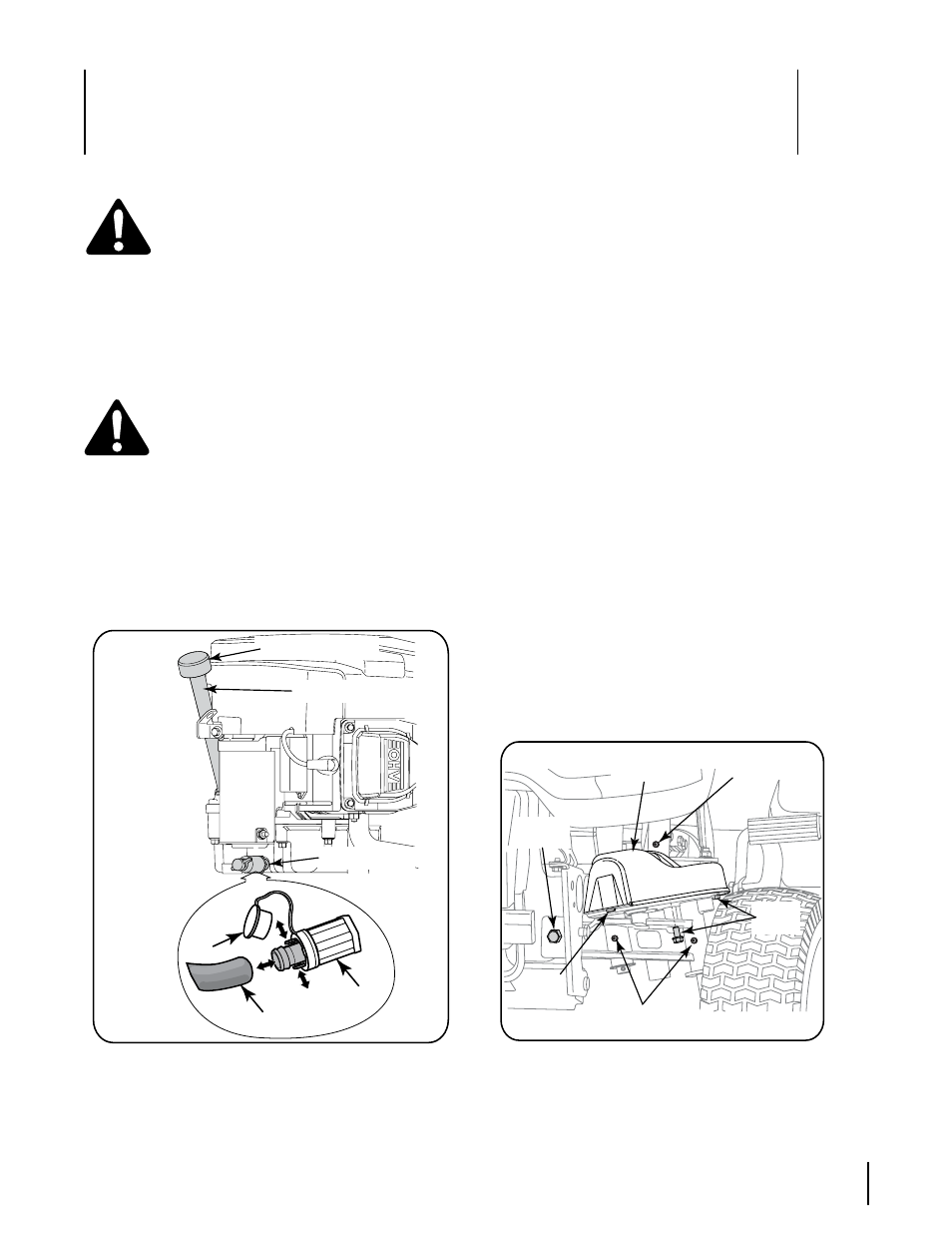

Locate the oil drain port on the right side of the engine.

Pop open the protective cap on the end of the oil drain

valve to expose the drain port. See Figure 6-1. Remove

the oil fill cap/dipstick from the oil fill tube.

Figure 6-1

Push the oil drain hose (packed with this manual) onto

the oil drain port. Route the opposite end of the hose

into an appropriate oil collection container with at least

a 2.5 quart capacity, to collect the used oil.

1.

2.

3.

4.

Pinch the tabs on the oil drain valve, then pull outward

to begin draining oil. Refer to Figure 6-1.

After the oil has finished draining, push the end of the

oil drain valve back in, until the tabs click into place.

Re-cap the end of the oil drain valve to keep debris

from entering the drain port.

Replace the oil filter, and refill the engine with new oil

as instructed in the Kohler Owner’s Manual.

Air Cleaner

Service the pre-cleaner and cartridge/air cleaner element

as instructed in the Kohler Owner’s Manual.

Spark Plug

The spark plugs should be cleaned and the gap reset once

a season. Refer to the Kohler Owner’s Manual for correct

plug type and gap specifications.

Hydrostatic Transmission

The zero turn tractor is equipped with dual integrated

hydrostatic pumps/transaxles that are sealed and are

maintenance-free. Fluid levels cannot be checked and fluid

cannot be added or changed.

Steering Lubrication

The steering arms, pivot shafts, and axles must be lubri-

cated if ever the steering effort increases, or after every

25 hour of operation. Lubricate using a pressure grease

gun and Cub Cadet 251H EP grease, or an equivalent No. 2

multipurpose lithium grease.

Apply grease through the lube fitting on the RH and LH

steering arms which are located at rearward end of the

two steering drag links. See Figure 6-2.

Figure 6-2

Locate the lube fittings for the pivot shaft and axle on

the front of one end of the axle pivot bar. Apply grease

through the two lube fittings, then repeat to lubricate

the other end of the pivot bar. See Figure 6-2.

5.

6.

7.

•

•

Axle Pivot Bar

Lube Fittings

Shoulder

Bolt

Hex

Screw

Steering

Gear Cover

Cover

Tab

Steering Arm

Lube Fitting

Oil Fill Tube

Oil Drain Valve

Dipstick/Oil Fill Cap

Cap

Drain

Drain

Hose

Valve