Checkline LS-SCU User Manual

Page 4

- 4 -

4.0 A

SSEMBLY AND

C

ONNECTION

The power can be supplied either via the installation under observation or the

stroboscope’s own power supply. Alternatively, power can be supplied via a

power supply unit (optional).

The function of the stroboscope control unit is to control a stroboscope.

In addition, it can be used to influence an incoming trigger signal from an

external system.

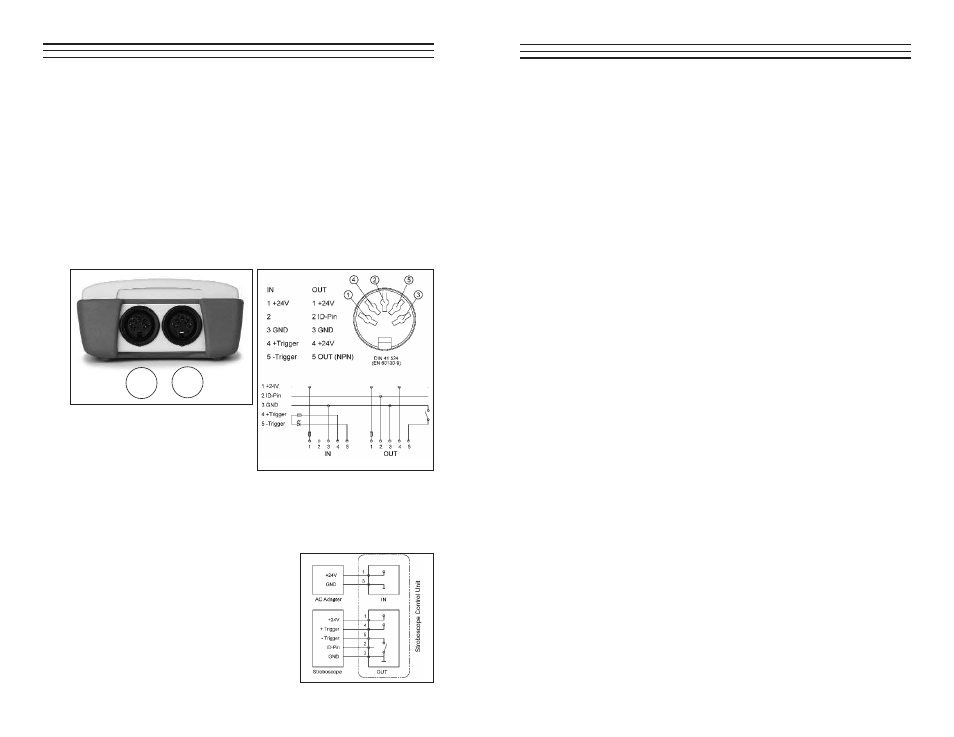

This device has two jacks. Power can be supplied via either of these jacks. The

jack for trigger input from an external system or sensor is labeled IN. The jack

for trigger output to a stroboscope is labeled OUT. The position of the jacks is

indicated in (Fig. 1). The wiring of the connectors is shown in (Fig. 2)

4.1 Typical

Wiring

Options

Please see Figs. 3-6 for examples of wiring options. Please note that

you need optional accessories for the examples (such as an stationary

stroboscope, power supply unit or sensor).

Fig 3. Trigger signal from this

instrument. Power supply

from the power supply

unit (optional).

IN

OUT

Fig.1

Fig. 2

- 9 -

6.0 H

INTS AND

S

UGGESTIONS

Problem:

The trigger signal is generated before the required observation

point.

Result:

The stroboscope flashes too early.

Solution:

Set a time delay between the input and output signals in ms

steps until the stroboscope delivers the required view.

Problem:

Your equipment is consistently transmitting the trigger signal

before location to be observed. However, your equipment runs at

different speeds.

Result:

Your stroboscope flashes at different locations, some of which

are unusable.

Solution:

Use phase shift (in degrees) to permanently shift the flash

position. The stroboscope will now adapt automatically to

changing speeds and will flash at a location which is shifted by

the set angle.

Problem:

An external trigger (e.g. a sensor) is monitoring a gear-wheel. Its

frequency is many times greater than the required flash frequency.

Result:

You don't receive the required control image.

Solution:

Instead of using each input signal, the impulse divider only

triggers a flash impulse after every 10th, 25th or 255th input

signal. Set the value in key steps or in "continuous flow" mode

until the required result is displayed.

Problem:

You need measurement values to be displayed in a variety

of formats.

Solution:

You have the following options: the instrument can display

FPM, RPM or Hz.