Introduction/installation, The miniqv-x automatic viscometer – Cannon Instrument miniQV-X User Manual

Page 7

1

CANNON

®

miniQV-X Automatic Viscometer with VISCPRO

®

Instruction & Operation Manual

Version 1.0— October, 2008; CANNON

®

Instrument Company

2139 High Tech Road • State College, PA 16803 • USA

1

INTRODUCTION/INSTALLATION

The miniQV-X Automatic Viscometer

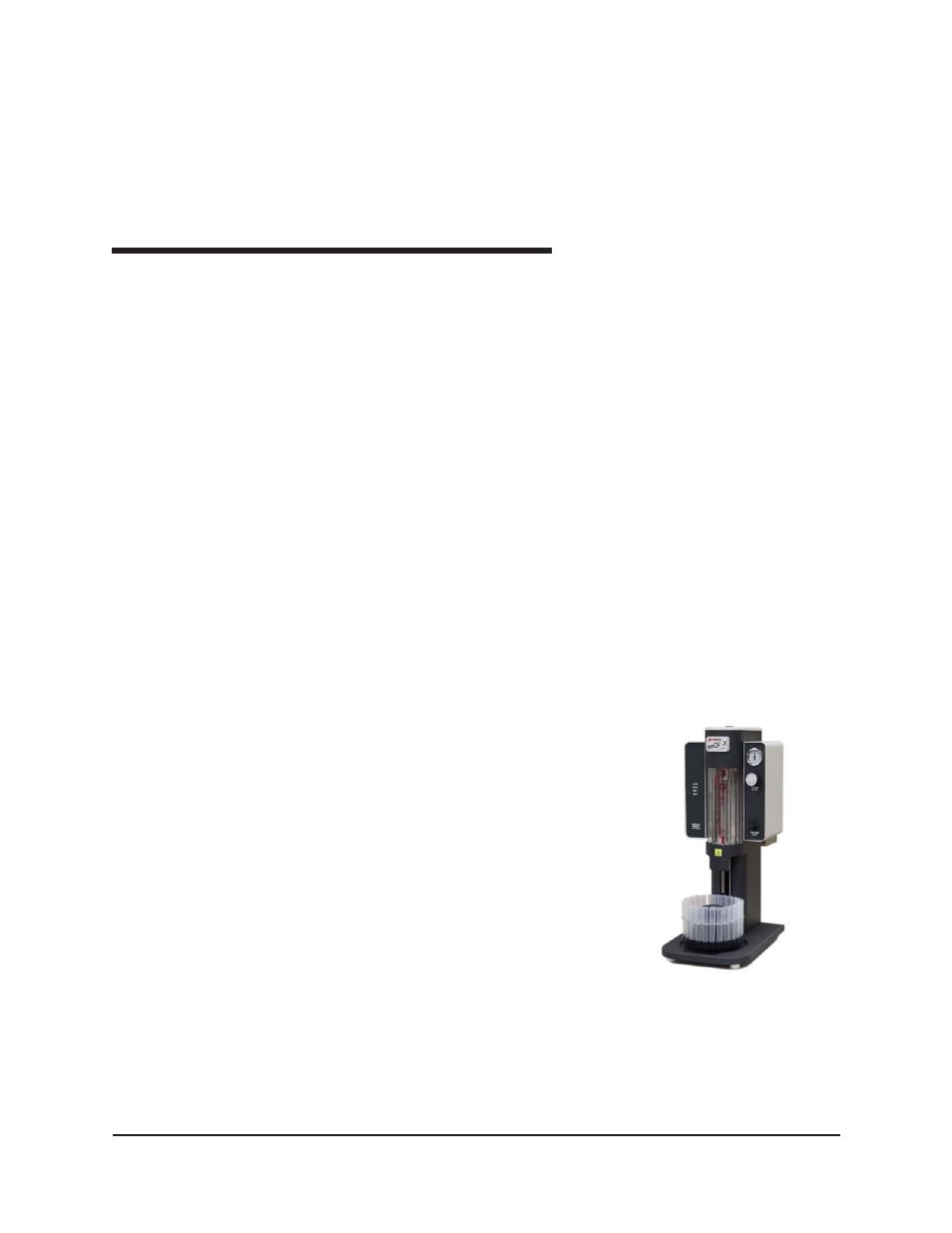

The miniQV-X Automatic Viscometer is designed to automate the time-

consuming sample testing and cleaning operations required for determi-

nation of kinematic viscosity in accordance with ASTM D445 specifica-

tions. The operator places the test sample(s) in small vials in the sample

holder(s), enters sample identification information from the computer

keyboard, and initiates testing with software keypad commands. Without

any further operator involvement, the miniQV-X determines kinematic

viscosity and cleans the capillary tube(s) in preparation for the next test.

All pertinent test data can be saved to a computer database for future

retrieval and reporting.

Manual

This manual is designed to provide the operator with information about:

VISCPRO

®

software installation and operation

miniQV

®

-X equipment, installation and operation

Calibration, service and maintenance procedures

Applications

miniQV-X instruments are appropriate for many kinematic viscosity

measurement applications in R&D laboratories, refinery quality control

laboratories, blending plants, and

independent testing laboratories. The

miniQV-X is ideally suited for the

analysis of both transparent and opaque

samples. A variety of materials, such as

used oils, marine fuels, residual fuels,

and crude oils can be tested with ease.

Precision

Precision for the kinematic viscosity

determination of the miniQV-X equals

or exceeds that specified in ASTM

Method D445. This method is required

by the Society of Automotive Engineers

(SAE) Engine Oil Viscosity Classifica-

tion SAE J300.

The miniQV-X™