8 troubleshooting, 1 malfunctions and their remedy, Malfunctions and their remedy – BUCHI Rotavapo R II User Manual

Page 39: 8troubleshooting, 8 .1 malfunctions and their remedy

8 Troubleshooting

39

R II Operation Manual, Version E

8

Troubleshooting

This chapter helps to resume operation after a minor problem has occurred with the instrument. It lists

possible occurrences, their probable cause and suggests how to remedy the problem.

The troubleshooting table below lists possible malfunctions and errors of the instrument. The operator

is enabled to correct some of those problems or errors by him/herself. For this, appropriate corrective

measures are listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a BUCHI technical

engineer who has access to the official service manuals. In this case, please refer to your local BUCHI

customer service agent.

8 .1

Malfunctions and their remedy

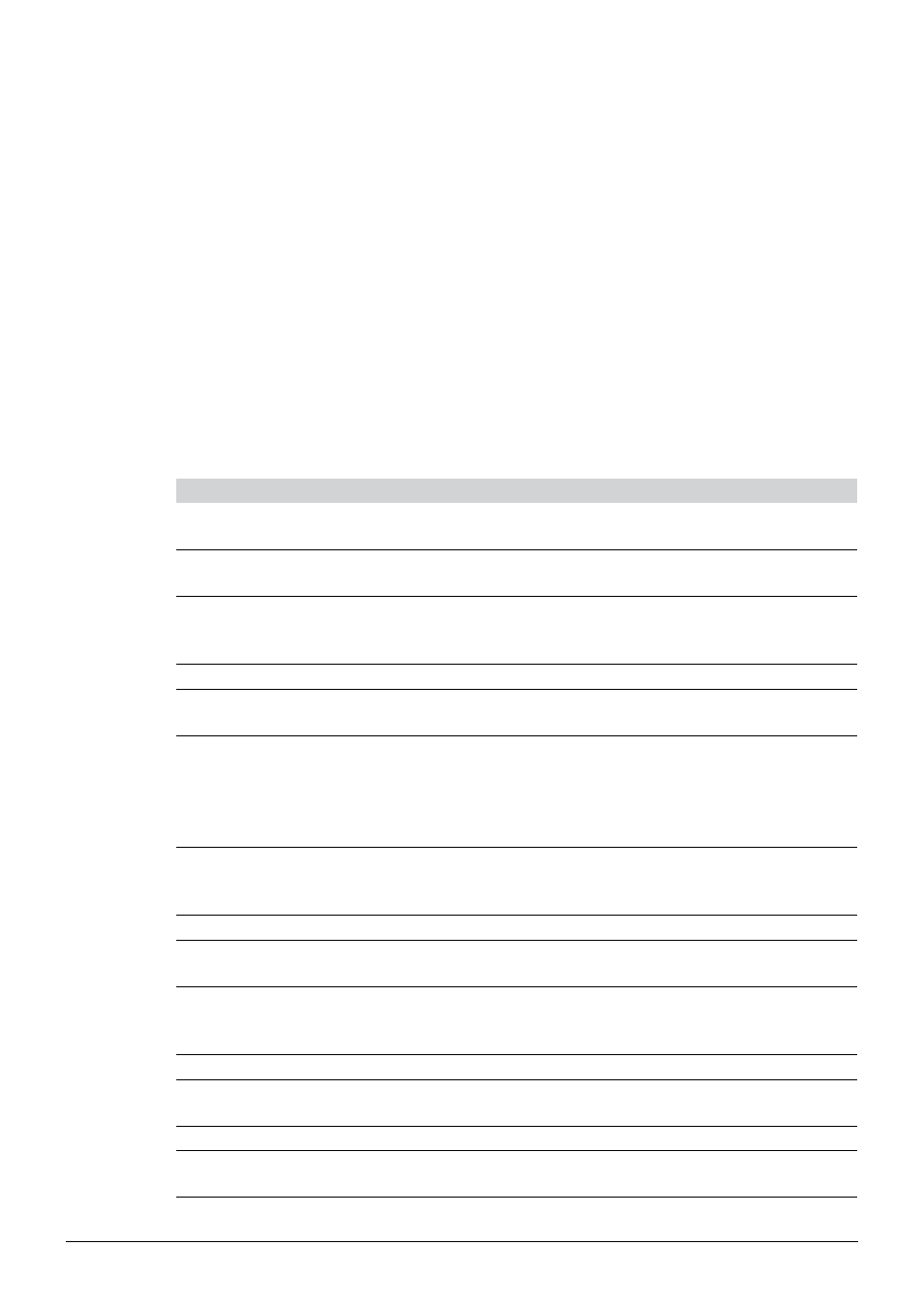

Table 8-1: General malfunction and their remedy

Malfunction

Possible cause

Corrective measure

Instrument does not work

Mains switch off

Switch on mains switch

Instrument is not connected to power

supply

Check if mains connection is okay

Fuse defective

Replace the fuse. If the malfunction

occurs again, contact the BUCHI

customer service.

Bath does not heat

Mains switch off

Switch on mains switch

Instrument is not connected to power

supply

Check mains connection

Over temperature protection was

activated

Let the bath cool down and empty it.

Then push the temperature sensor

reset button at the bottom side of the

heating bath e.g. by means of a tooth

stick, see Fig. 8.1.

Fuse defective

Replace the fuse. If the malfunction

occurs again, contact the BUCHI

customer service.

Servo lift does not work

Various causes

Contact the BUCHI customer service

Flask does not rotate

Adjusting knob for rotation speed

at 0

Turn adjusting knob for rotation

speed clockwise until rotation starts

Restart instrument

Turn adjusting knob for rotation

speed to 0 then slowly turn clock-

wise until rotation starts

System is leaking

Joints have not been greased

Grease joints

Tube connections have not been

fixed correctly or are defective

Check tube connections

Tubes are leaky (brittle)

Replace tubes

Sealing system has been installed

incorrectly

Check sealing system