Blue Sky Solar Boost 3024iL User Manual

Page 9

Installation and Operation Manual

8

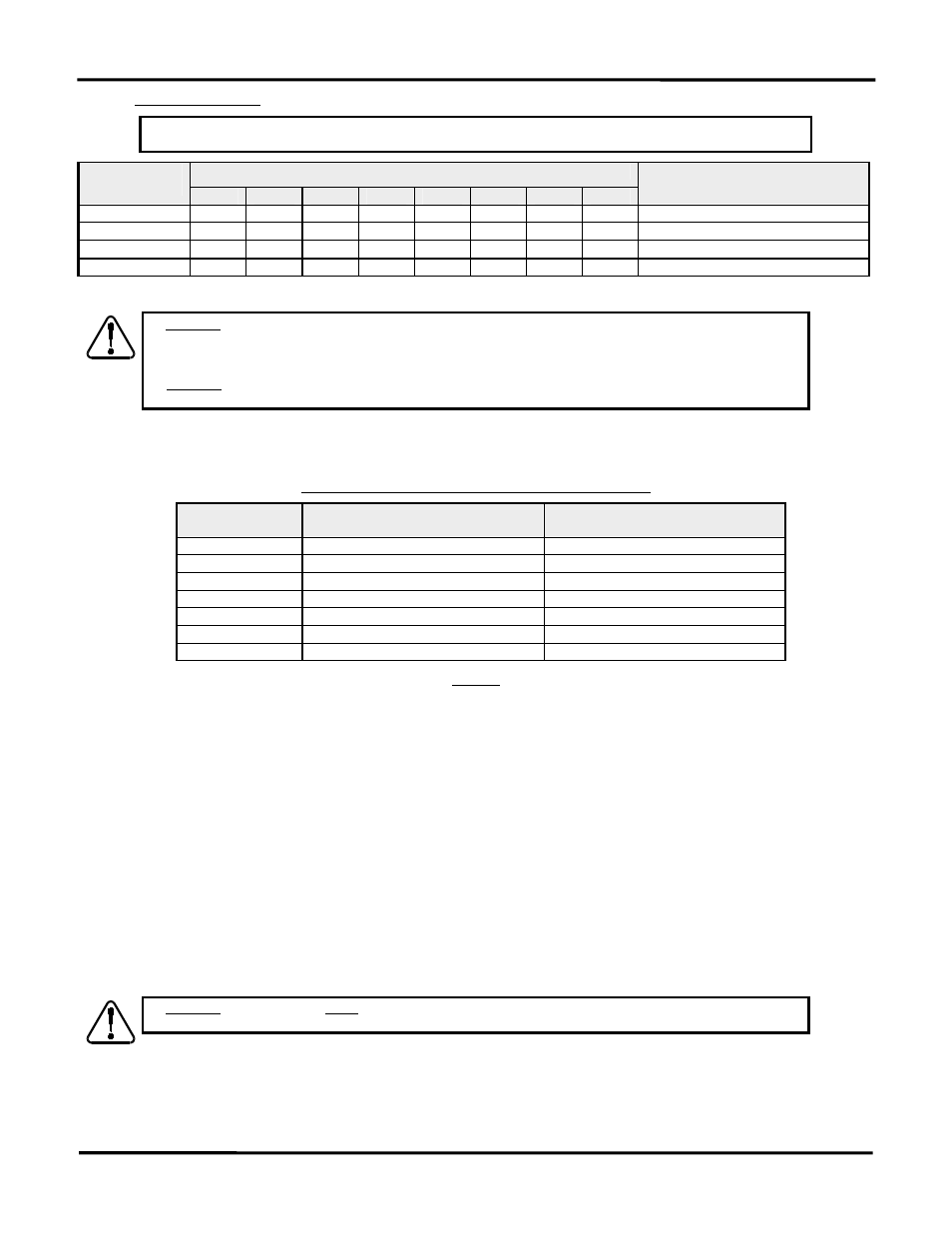

Output Current Display (SB3024DiL only)

¾

The display can show total output current from all networked controllers, or the output current of a single controller. To show

output current from a single controller IPN network address of the display and charge controller must match.

IPN ADDRESS – OUTPUT CURRENT OF SINGLE CHARGER UNIT

DISPLAY BOARD

DIP SWITCH

0

1

2

3

4

5

6

7

TOTAL OUTPUT CURRENT OF ALL

CHARGERS ON IPN NETWORK

# 1 (A2)

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Don’t care

# 2 (A1)

OFF

OFF

ON

ON

OFF

OFF

ON

ON

Don’t care

#

3

(A0) OFF ON OFF ON OFF ON OFF ON

Don’t

care

# 4 (IPN Total)

OFF

OFF

OFF OFF OFF OFF OFF OFF

ON

BATTERY AND PV WIRING

¾

CAUTION: Battery and PV compression terminals accept #14

−4 AWG wire and are tightened to 45 in-lb (5 nm). IPN network

compression terminals accept #24

−14 AWG wire and are tightened to 2.1 in-lb (0.24 nm). Auxiliary Output compression

terminals accept #24

−12 AWG wire and are tightened to 6 in-lb (0.67 nm).

¾

CAUTION: DO NOT connect Bat– and PV– together external to the 3024 or improper operation will result. Bat– and PV–

connect together internally.

A desirable installation would produce a total system wiring voltage drop of 3% or less. The lengths shown in Table 2 are one way from the PV to the battery

with the 3024 located along the path. Wire length can be increased inversely proportional to actual current. If current was reduced by ½, wire lengths could doubled

and still provide 3% voltage drop.

MAXIMUM CONDUCTOR PAIR LENGTH - 3% VOLTAGE DROP

WIRE GAUGE

AWG

12 VOLT SYSTEM @32A

FEET / METERS

24 VOLT SYSTEM @24A

FEET / METERS

12 AWG

4.0 / 1.2

10.7 / 3.3

10 AWG

6.4 / 2.0

16.9 / 5.2

8 AWG

10.1 / 3.1

26.9 / 8.2

6 AWG

16.1 / 4.9

42.8 / 13.0

4 AWG

25.5 / 7.8

68.1 / 20.7

2 AWG

40.6 / 12.4

108.2 / 33.0

1/0 AWG

64.6 / 19.7

172.2 / 52.5

TABLE 2

ELECTROMAGNETIC COMPATIBILITY

To comply with electromagnetic compatibility requirements the 3024’s battery and PV wiring must be installed in grounded metallic conduit, and the two

clamp on type ferrite suppressors supplied must be installed. Clamp one suppressor around both Bat+ and Bat– cables. Clamp the second suppressor around

both the battery temperature sensor and remote display cables with the cables looped to pass through the core 3 times. If both sensor and display cables are

used, the sensor cable outer cover must be stripped back

≈12” (30cm) so both cables will fit through the core 3 times. Ensure that the two suppressors are

restrained so they will not damage circuit board components. Additional suppressors can be ordered as BSE p/n 523-0005-01.

BATTERY TEMPERATURE SENSOR

Installation of the optional battery temperature sensor enables temperature compensation of all charge voltage setpoints. In a multi-controller system a

single temperature sensor must connect to the IPN master. Do not attach a sensor or connections other than Blue Sky Energy battery temperature sensor p/n

930-0022-20. Be certain to observe proper RED/BLK polarity.

AUXILIARY OUTPUT

The auxiliary output can serve one of three functions; a 2A auxiliary battery charger, a 20A load controller with Low Voltage Disconnect (LVD), or a 20A

variable Dusk-to-Dawn lighting load controller. The Charge/Load function is selected by DIP switch #4 shown in Figure 3. The IPN-ProRemote is required to adjust

LVD thresholds or enable Dusk-to-Dawn lighting control. Auxiliary outputs in a multi-controller system will function normally, but only the auxiliary output in the

master can be configured or monitored using the IPN-ProRemote. The auxiliary output “Load” LED will illuminate whenever the auxiliary output is ON.

¾

CAUTION: The auxiliary output cannot perform both auxiliary battery charge and load control functions at the same time. Do not

connect to the 20A Load terminal for auxiliary battery charge.

)