General information assembling vent pipes, Fp1471 flex vent, Flex vent pipes – Vermont Casting DV580 User Manual

Page 15: Termination clearances

15

DV360/580 Series Direct Vent Gas Fireplace

20010667

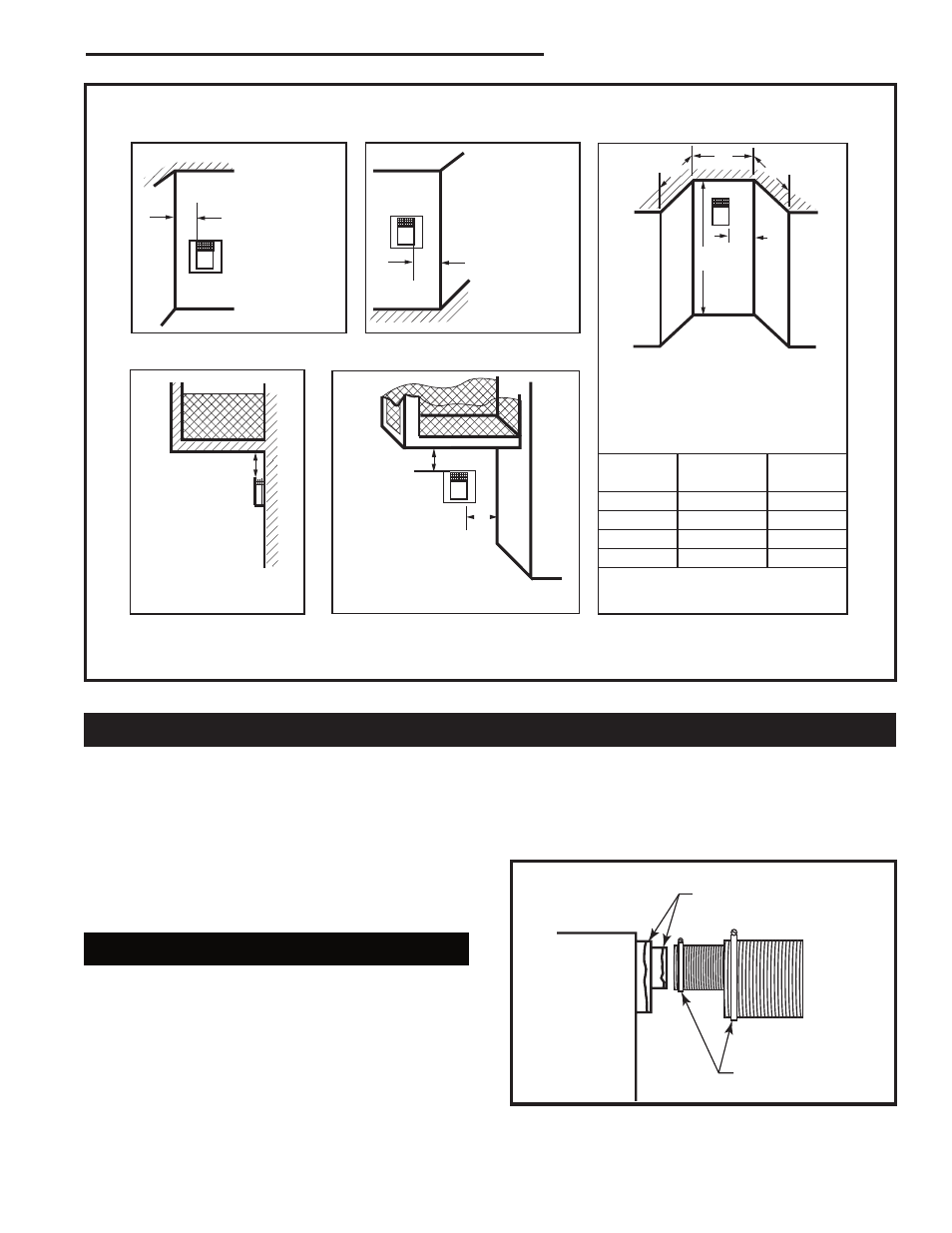

Fig. 16 Termination clearances.

General Information Assembling Vent Pipes

Canadian Installations

The venting system must be installed in accordance

with the current CSA-B149.1 installation code.

USA Installations

The venting system must conform to local codes and/or

the current National Fuel Code ANSI Z223.1/NFPA 54.

Only venting components manufactured by CFM Cor-

poration may be used in Direct Vent systems.

Flex Vent Pipes

Before joining the flex vent pipe to the unit, apply a

bead of high temperature sealant* (provided) to the 4”

pipe exiting the fireplace. Secure flex vent piep in place

with a hose clamp (provided).

*Be sure the flex pipe overlaps at least 1” (25mm) onto

the collars of the fireplace and termination. If the ter-

mination has an internal bead, be sure to overlap and

secure 1” (25 mm) past the bead.

* Be sure the vent is actually crushed before proceed-

ing. Apply a tug to be sure the vent will not slip off the

collars.

Repeat process with 7” flex vent pipe. The same proce-

dure must be performed on the vent side.

FP1471

flex vent

Apply High Temperature

Sealant

Hose Clamp

FP1471

Fig. 17 Apply high temperature sealant to 4” and 7” pipes.

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

G =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

G

Balcony -

with no side wall

M =

Combustible &

Noncombustible

12" (305 mm)

M

Balcony -

with perpendicular side wall

M = 24" (610 mm)

P = 20” (508 mm)

M

F

Alcove Applications*

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

E

= Min. 6” (152 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O

= 8’ (2.4 m) Min.

O

P

584-15

No.

of Caps

D

Min.

C

Max.

1

3’ (914 mm) 2 x D

Actual

2

6’ (1.8 m)

1 x D

Actual

3

9’ (2.7 m)

2/3 x D

Actual

4

12’ (3.7 m)

1/2 x D

Actual

D

Min.

= # of Termination caps x 3

C

Max.

= (2 / # termination caps) x D

Actual

*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions

specified for vinyl or non-vinyl siding and soffits. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All

mechanical air intakes within 10’ (1 m) of a termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All

gravity air intakes within 3’ (914 mm) of a termination cap must be a minimum of 1’ (305 mm) below the termination cap.