Iii. damper motor components, Ii. wiring – Beckett SQM40 User Manual

Page 2

2

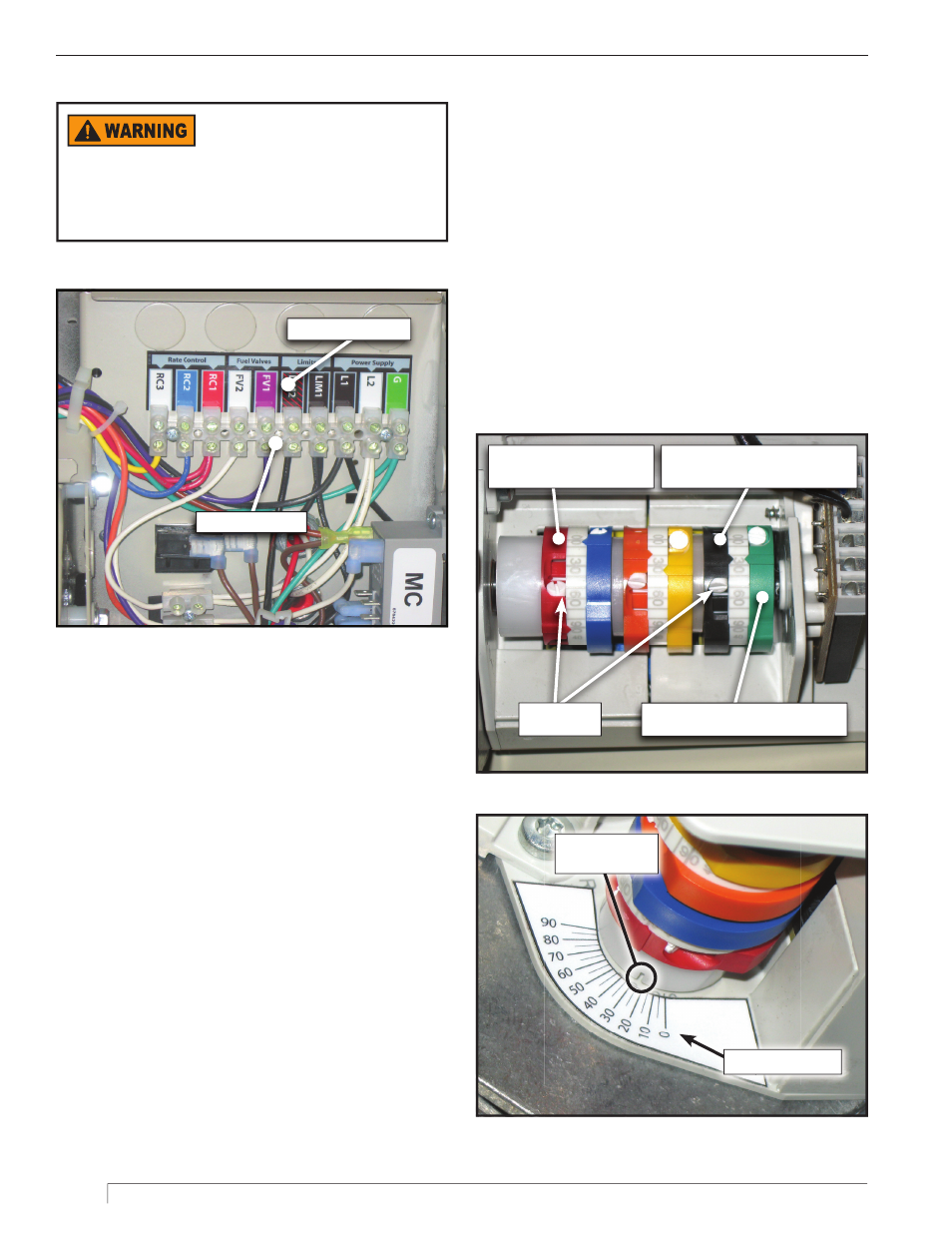

III. Damper Motor Components

The damper motor positions for high fi re and for low fi re

are set by adjustment of individual cams in a cam stack

(Shown in

Figure 3

). Only three of the cams in this

motor are active, the red, black and green cams.

○

The red cam limits the maximum position of the

motor to the burner’s high fi re setting.

○

The black cam limits the minimum position of the

motor to the burner’s low fi re setting.

○

The green cam could be used to set a third position,

for example an off position for the damper. We do

not use the green cam, but we recommend that it be

set to the same position as the black cam.

Indicating Notch for

Damper Position

Damper Position Scale

Figure 4

Red High Fire Cam

(Example:Red Pointer set at 90)

Black Low Fire Modulation Limit Cam

(Example: Black Pointer set at 25)

Green Low Fire Limit Cam

(Example: Green Pointer set at 25)

Figure 3

II. Wiring

Color Coded Label

Terminal Strip

Figure 2

Electric Shock Hazard

Turn off all electric power to the burner before

servicing.

y

If power is required for adjustments, use extreme

care while working near live conductors.

For standard construction burners the junction

box contains a color coded terminal strip showing

connections for control system power (and blower

motor power for 120 VAC blower motors), limit string

connections, gas valve connections, and rate control

connections. The terminal strip markings match the

wiring diagram specifi c to your burner. All of your

control connections are to be made to this terminal

strip. For burners with blower motors operating at a

voltage greater than 120 VAC the junction box will have

a separate motor contactor section with its own power

connections. Refer to the wiring diagram supplied with

your burner for connection details.

Adjusting

Screws