Trouble shooting – Wilbur Curtis WB-10-60 User Manual

Page 4

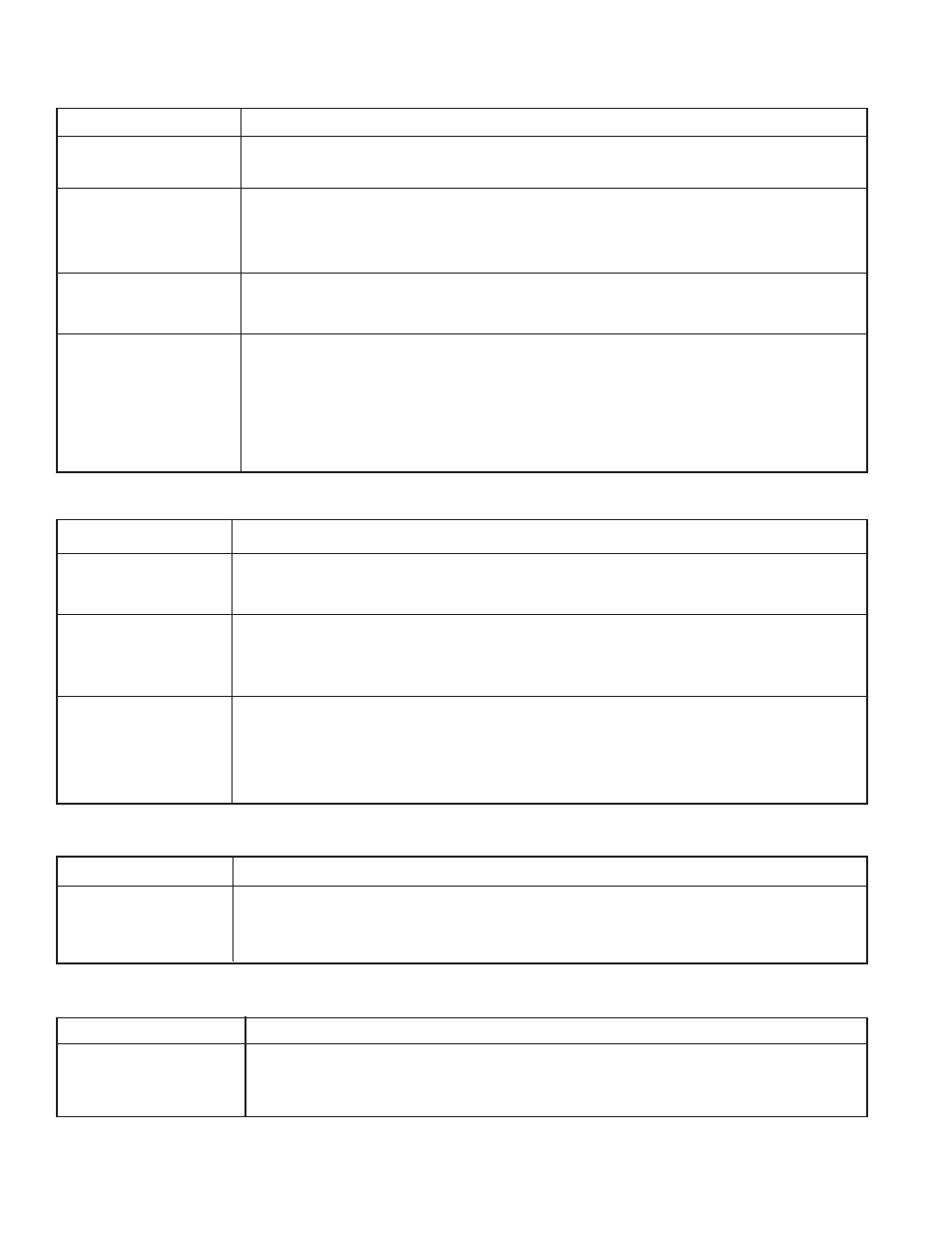

PROBLEM: WATER OVERFLOWING.

POSSIBLE CAUSE

SOLUTION

Turn power off and observe water level. If water continues to flow into the heating tank, clean or

replace leaky valve.

Disconnect wire from probe terminal. Touch the body of the heating tank with the terminal at the end

of this wire. If the flow of water stops, there is and issue with the probe. Clean the probe and recon-

nect the wire. If water continues to flow, replace the liquid level probe.

Liquid level control board must be securely grounded through the back of the board and the mount-

ing bracket. Check for loose connections at the terminals. Check for voltage across the inlet valve

terminals. If there is 110 to 120 volts present at the inlet valve terminals when water level is touching

the probe tip, replace the L.L.C. board.

1. Defective water inlet

valve

2. Liquid level probe

limed up

3. Non-grounded or loose

terminal connections

at liquid level control

board

TROUBLE SHOOTING

POSSIBLE CAUSE

SOLUTION

PROBLEM: WATER WILL NOT REFILL

1. Water line closed or

clogged filter

2. Valve coil burned out

3. Grounded probe

4. Defective water level

control board

Check the water system at your facility to make sure the line is open. Replace the water filter.

Turn machine off. Disconnect wires from water inlet coil terminals and connect a power cord to

the terminals. Plug cord into a 120V outlet and verify if water flows when plugged in and stops

when power is disconnected. If valve fails this test, replace valve.

When the water level gets below the probe tip, water should automatically refill the unit. If not, pull

wire off the probe terminal. Water should now start flowing into the water boiler.

Disconnect wire from probe terminal. With a voltmeter, check voltage at the water inlet coil termi-

nals. This should read 110-120 volts. If no voltage is present, check liquid level control (L.L.C.)

board. Make sure the L.L.C. board is supplied by 120V across terminals NEU and L1 120V. The

L.L.C. board is grounded to the body of the machine by contacting the board to the mounting

bracket. Make sure board is grounded here. Check for loose connections at terminals. Replace

the L.L.C. board.

POSSIBLE CAUSE

SOLUTION

1. Thermostat is turned

OFF (or set too low)

Check the thermostat adjustment to make sure the knob is rotated clockwise to the desired tem-

perature setting.

PROBLEM: WATER DOES NOT REACH PROPER TEMPERATURE

SOLUTION

POSSIBLE CAUSE

PROBLEM: WATER OVERHEATS, ELEMENTS DO NOT SHUT OFF

Replace the thermostat. You can sometimes operate temporarily by turning the thermostat knob

to off until the boiling stops.

1. Defective thermostat

4