Thermopro brewing systems, Thermoserver cleaning – Wilbur Curtis THERMOPRO – CLEANING User Manual

Page 2

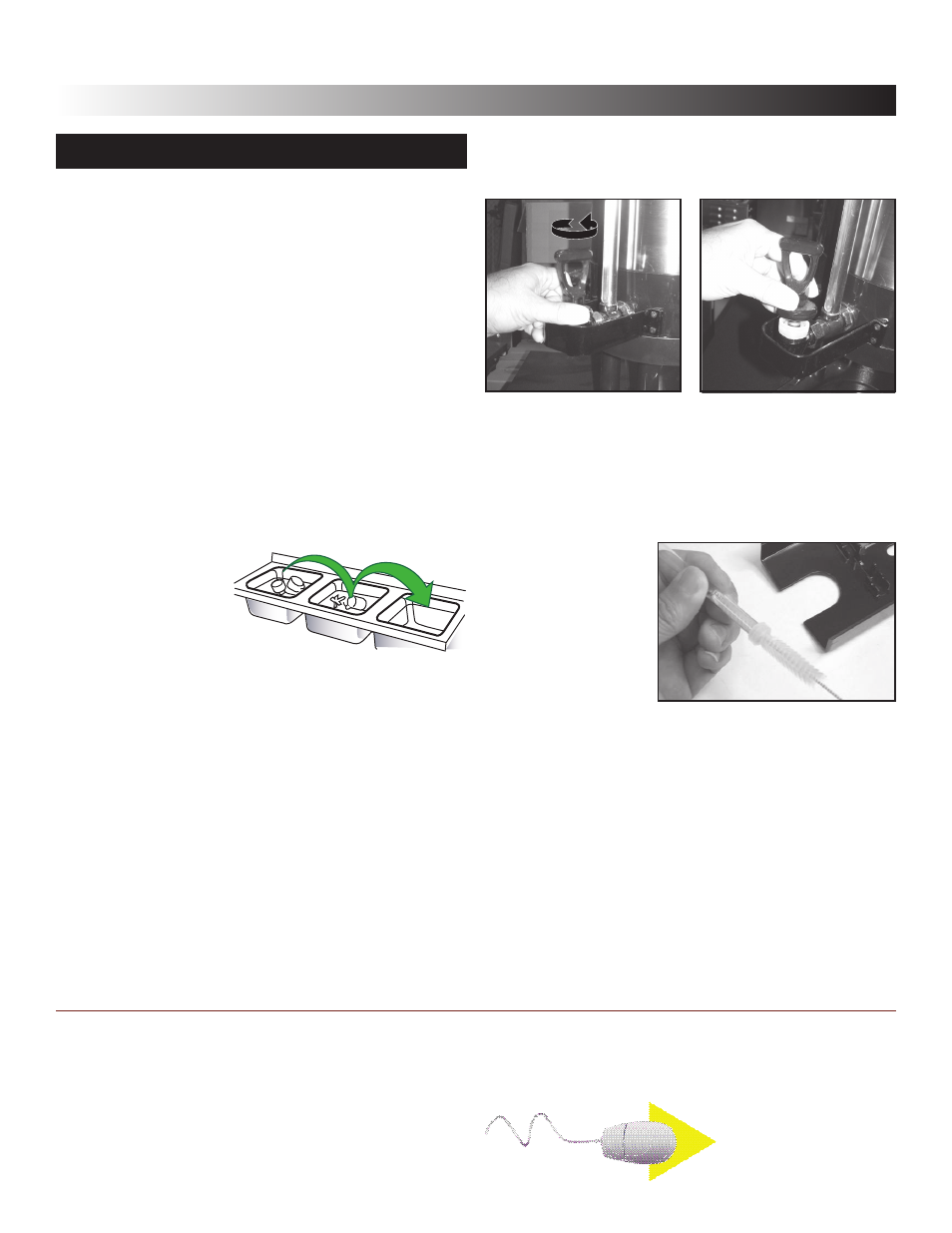

CLEANING OF THERMOSERVER FAUCET

1. Twist the faucet handle assembly counterclockwise to remove it from

the faucet. Disassemble the parts from the faucet handle.

2. Clean the seat cup, and other faucet parts with a mild detergent solu-

tion. When clean, rinse the parts. Inspect for cracks or tears in the

seat cup. Replace if damaged.

3. Clean the glass gauge.

a.Remove the sight

glass cover by pulling up

and off from the server.

b.Using the narrow

brush provided for this

purpose, brush out the

inside of the glass with a

mild detergent solution.

Rinse the sight glass tube of all detergent.

c.Replace the sight glass. Make sure silicone seals are seated.

d.Pay special attention to the small gauge glass liquid level hole

on the body of the faucet. You can brush this out with a small pipe

cleaner.

CLEANING THE STAINLESS STEEL LINER

1. Rinse out the liner with hot water to remove coffee from the server.

2. Fill the liner with a mild detergent solution and let it stand for 10 to

15 minutes.

3. After about 15 minutes take a sponge and scrub out the

stainless steel liner.

4. Completely drain out the soapy solution from the liner.

5. Fill the airpot with clean water to rinse out any detergent left inside

the unit. Repeat this rinsing several times until the water runs clear

and free of all traces of detergent solution.

CLEANING OF THERMOSERVER PARTS

This insulated server is designed to be easily disassembled for mainte-

nance.

Use three sinks to clean and sterilize airpot parts. Fill one sink with tepid

water containing detergent.

In the second sink pour a

sterilizing solution (follow

product manufacturer’s

instructions for mixing).

Fill the last sink with clean water for rins-

ing.

1. In the sink filled with the detergent solution, clean the removed parts.

Use a small, soft bristled brush to clean hard to reach areas.

2. Rinse the parts in clear water.

3. Place the parts into the sterilization sink and immerse for five minutes.

4. Rinse the solution from the parts.

5. Allow all cleaned parts to completely air dry.

6. Assemble the dried parts onto the server.

THERMOPRO BREWING SYSTEMS

WILBUR CURTIS COMPANY, INC.

6913 Acco Street, Montebello, CA 90640-5403

Telephone: 800-421-6150 323-837-2300

Fax: 323-837-2406

Printed in U.S.A. 11/07 F-3363 rev A

find the latest on the web at

www.wilburcurtis.com

THERMOSERVER CLEANING

11/12/7 . 12.7 . ecn 9374

4/6/04 . 9.0 . edr 4003