Steam connection, 9 steam connection – B&C Technologies SI Series Industrial User Manual

Page 27

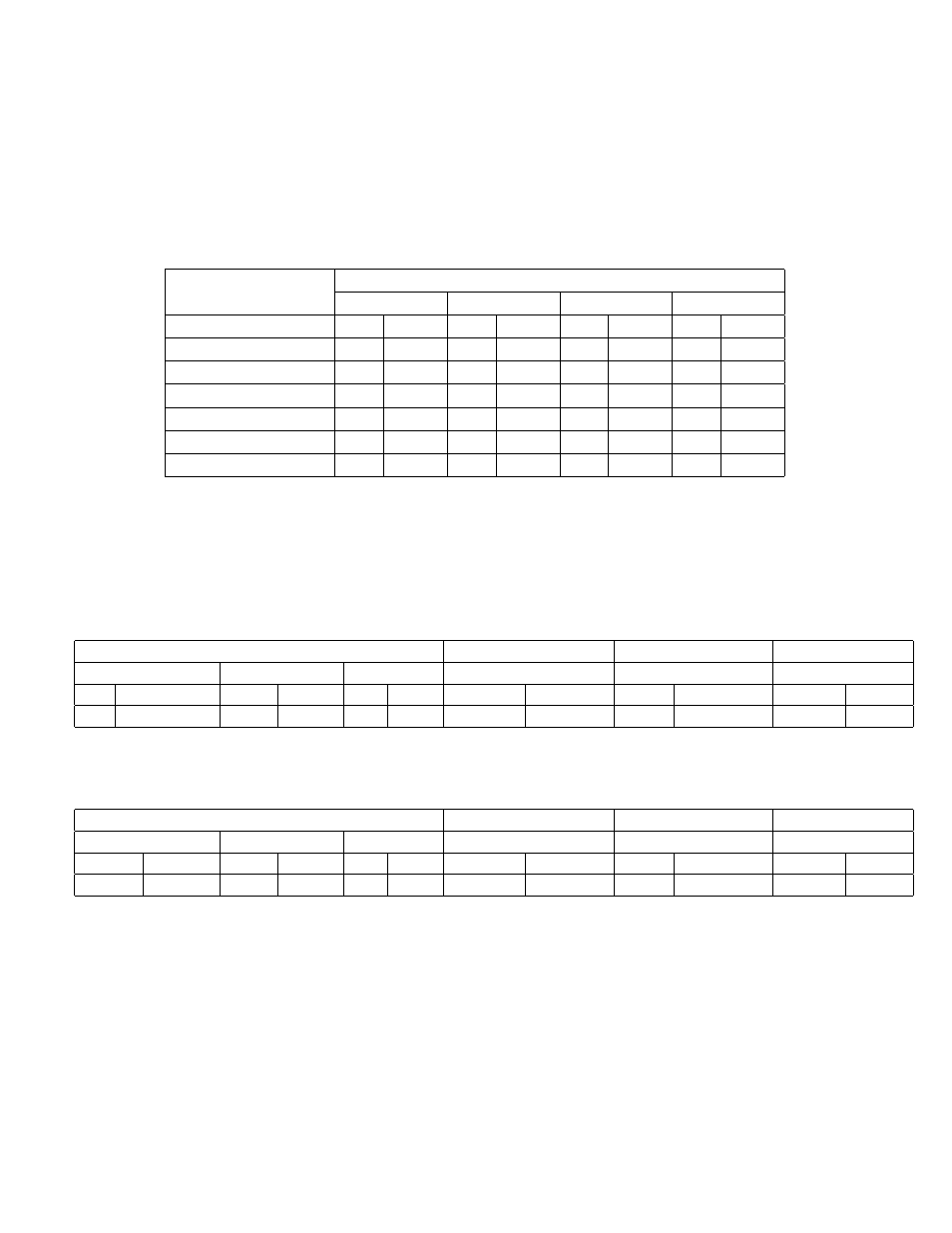

particles out of the solenoid valves. Hang the hoses in a large loop. Do not allow the hoses to

kink. The water connections to the machine should be supplied by a hot and cold water line of

least the sizes shown in table 5.4 on page 23. Refer to table 5.5 and 5.6 on page 23 for details on

individual machine requirements.

Table 5.4: Water Connection Detail

# OF MACHINES

SUPPLY LINE PIPE SIZES

SI-110

SI-135

SI-200

SI-275

DN

Inch

DN

Inch

DN

Inch

DN

Inch

1

25

1

32

1-1/4

32

1-1/4

40

1-1/2

2

25

1

32

1-1/4

32

1-1/4

40

1-1/2

3

40

1-1/2

50

2

50

2

50

2

4

40

1-1/2

50

2

50

2

50

2

5

50

2

63

2-1/2

63

2-1/2

63

2-1/2

6

50

2

63

2-1/2

63

2-1/2

63

2-1/2

To avoid eventual water hammer in the water line, suitable devices to reduce the water hammer

should be installed.

Table 5.5: SI-110 Water Requirements

Water

Flow Rate

Minimum Supply

Max Operating

Connection Size

Line Pressure

Max Temp

(@45PSI/3Bar)

Line Size

Pressure

US

Metric

PSI

Bar

F

C

gal/min

liter/min

US

Metric

US

Metric

1”

DN 25

30-75

2-5

200

93

30

113

1-1/4

DN 32

125 PSI

8 Bar

Table 5.6: SI-135 / SI-200 / SI-275 / SI-300 Water Requirements

Water

Flow Rate

Minimum Supply

Max Operating

Connection Size

Line Pressure

Max Temp

(@45PSI/3Bar)

Line Size

Pressure

US

Metric

PSI

Bar

F

C

gal/min

liter/min

US

Metric

US

Metric

1-1/4”

DN 32

30-75

2-5

200

93

37

140

1-1/2

DN 38

125 PSI

8 Bar

5.9

Steam Connection

For machines equipped with optional steam heat, install piping in accordance with approved com-

mercial steam practices. Steam requirements are shown in the table 5.7 on page 24. Failure to

install a steam filter/trap may void the warranty.

23