Wine-Mate SSDWC Series User Manual

Page 23

- 22 -

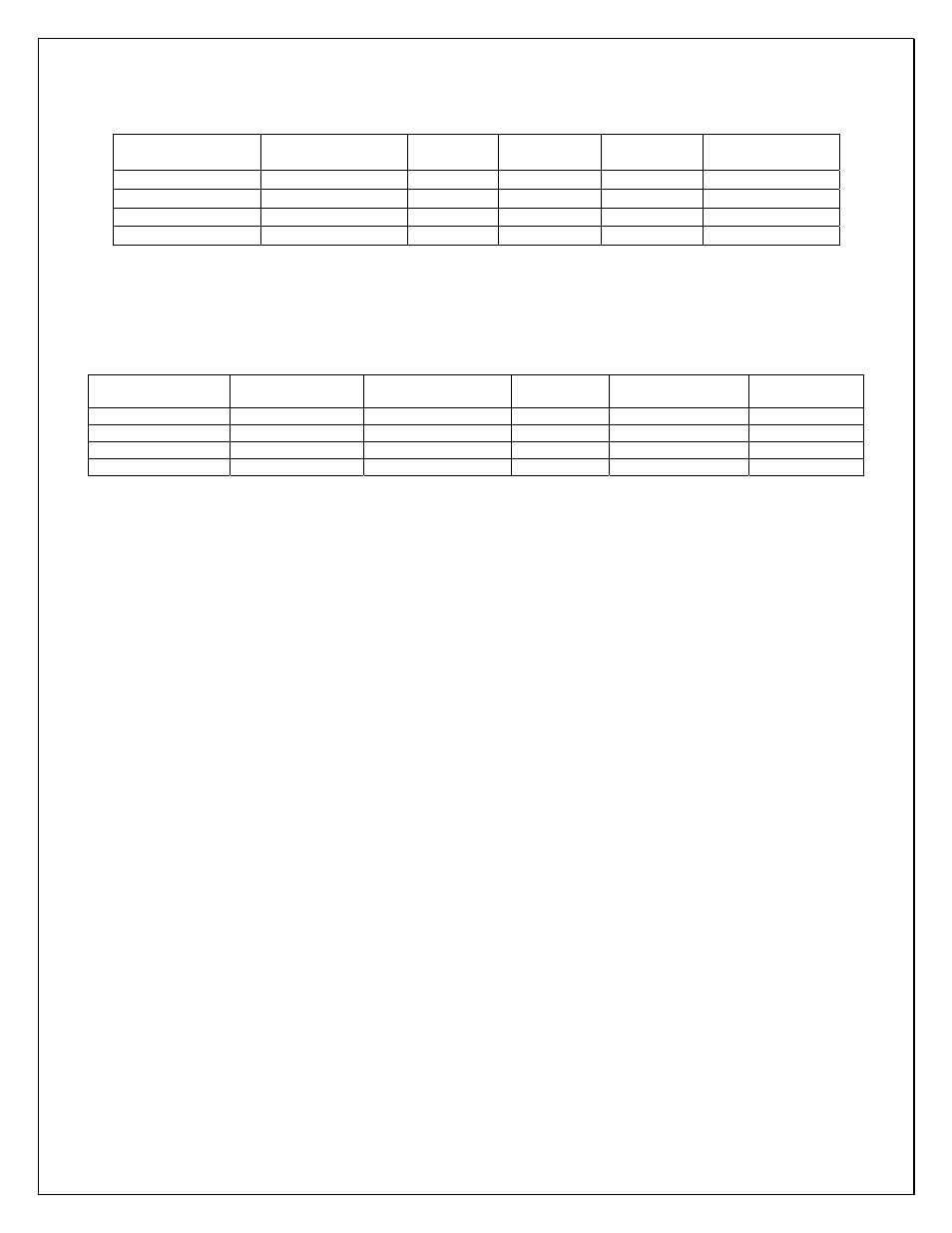

Model No

Equivalent

Line Set

Liquid

Line

Suction Line

Drain Line

Recommended

Charge

WM-2500SSDWC

<= 75 FT

1/4” OD

3/8” OD

1/2” OD

R134a/19 OZ

WM-4500SSDWC

<= 75 FT

1/4” OD

1/2” OD

1/2” OD

R134a/26 OZ

WM-6500SSDWC

<= 75 FT

1/4” OD

1/2” OD

1/2” OD

R134a/32 OZ

WM-8500SSDWC

<= 75 FT

3/8” OD

5/8” OD

1/2” OD

R134a/40 OZ

7. Water Piping

If a water pump is used, install it before the water inlet so that the condenser

cooling water is fed from the discharge side of the pump.

Model No

Condensing Unit

Water Flow

(75°F inlet, gal/min)

Water-in

Connection

Water-out

Connection

Water Pressure

Drop (PSI)

WM-2500SSDWC

WM-250SCU-WC

0.2

3/8” FPT

1/2" ODF SOLDER

0.2

WM-4500SSDWC

WM-450SCU-WC

0.4

3/8” FPT

1/2" ODF SOLDER

0.2

WM-6500SSDWC

WM-650SCU-WC

0.6

3/8” FPT

1/2" ODF SOLDER

0.2

WM-8500SSDWC

WM-850SCU-WC

0.8

3/8” FPT

1/2" ODF SOLDER

0.4

8. Connecting Electrical Wires

Connect all electrical components using the wiring diagrams in accordance with

all state and local codes.

9. Evacuating, Charging and Starting the system

CAUTION:

• Always use the superheat and subcooling, pressure readings to charge

refrigerant properly; the listed charge amounts are used for reference

only.

1) Evacuate the system; both discharge and suction valves must be in the

middle positions during evacuating.

2) Charge the system through both suction and discharge valves with refrigerant

using the recommended initial amount; both discharge and suction valves

must be in the middle positions during charging.

3) Turn on the water valve.

4) Turn on the power to start the system and check the following temperatures

and pressures.

10. Adjusting and Completing the installation

1) Set the water regulating valve opening set-point at refrigerant pressure of 120

PSIG. Turn counterclockwise to raise the operating set-point.